4XForOffroad

Well-known member

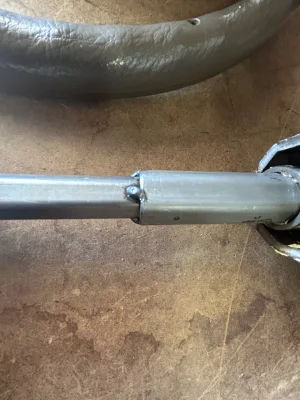

Fluid won’t take up slop in the gears, it’s just there to assist the movement under load and to lubricate. Whatever movement there is, is between the metal to metal contact in the rack. It might be helpful to remove everything down to the splined end of the pinion shaft and see if you’re getting the play without the rag joint attached although to remove any possibility that it’s play between the rag joint and the pinion shaft - although that doesn’t seem likely as the lower part of the rag joint would have to have been de-splined or really mashed in order for that to happen.

According to Dirty Pool on TW there should be no lash (I’m guessing he means perceivable lash) between the rack and pinion gears on the rack.

https://www.tacomaworld.com/threads/oem-steering-rack-rebuild-s.703995/page-2#post-28480143

Here’s a good view of the rack taken apart in a rebuild write up he made so you can see the inner workings of it:

https://www.tacomaworld.com/threads/rack-pinion-service-tools-tips.312600/#post-8072827

According to Dirty Pool on TW there should be no lash (I’m guessing he means perceivable lash) between the rack and pinion gears on the rack.

https://www.tacomaworld.com/threads/oem-steering-rack-rebuild-s.703995/page-2#post-28480143

Here’s a good view of the rack taken apart in a rebuild write up he made so you can see the inner workings of it:

https://www.tacomaworld.com/threads/rack-pinion-service-tools-tips.312600/#post-8072827