smokeysevin

Active member

- Joined

- Mar 7, 2023

- Messages

- 236

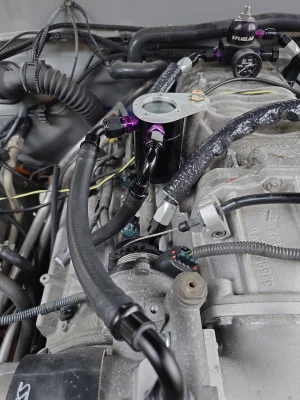

My second throttle showed up and I got to work dissecting it. My initial thinking was that I would just do a motor comparison and see where that got me as far as motor spec and control.

Stock Tundra throttle body

Tundra APPS, everyone assumes this is a cable driven throttle but that is just a sensor with a "limp home funciton" on it. If the sensor fails, you can get 20ish percent throttle if you go WOT with the pedal. We can mount the APPS sensor wherever, its big and annoying in the engine bay.

Jumping over to the drive side, the gearbox, motor, TPS, and motor clutch are in this gearbox.

Splitting the case gives you this, the motor and clutch are there in the bottom, and the dual TPS is up top.

On the other half is an integrated shaft, min/max throttle stop, and the gears as well as the tps fingers (nut and lock washer removed already, no proof)

Then I took the range rover throttle apart to see what if anything could be transferred. Start by drilling out the 6 rivets and popping the lid off.

Under the lid is a digital, hall effect/prox probe type sensor for the tps and the motor contacts.

Nylon/glass fiber reinforced gears, the motor, and throttle stops.

With the gear removed you can see the motor mounts and the gear a little better.

Motor removed, nothing special.

The gears mesh but the ratios are wrong, the stock tps on either setup would clash with the gears and the net result would still be not great. I went to sleep dejected.

Sean

Stock Tundra throttle body

Tundra APPS, everyone assumes this is a cable driven throttle but that is just a sensor with a "limp home funciton" on it. If the sensor fails, you can get 20ish percent throttle if you go WOT with the pedal. We can mount the APPS sensor wherever, its big and annoying in the engine bay.

Jumping over to the drive side, the gearbox, motor, TPS, and motor clutch are in this gearbox.

Splitting the case gives you this, the motor and clutch are there in the bottom, and the dual TPS is up top.

On the other half is an integrated shaft, min/max throttle stop, and the gears as well as the tps fingers (nut and lock washer removed already, no proof)

Then I took the range rover throttle apart to see what if anything could be transferred. Start by drilling out the 6 rivets and popping the lid off.

Under the lid is a digital, hall effect/prox probe type sensor for the tps and the motor contacts.

Nylon/glass fiber reinforced gears, the motor, and throttle stops.

With the gear removed you can see the motor mounts and the gear a little better.

Motor removed, nothing special.

The gears mesh but the ratios are wrong, the stock tps on either setup would clash with the gears and the net result would still be not great. I went to sleep dejected.

Sean