Copy and paste from other sites but same info.

Ok so I have a 1968 Ford F250 that was previously a prerunner and I am rebuilding it into a 4x4 badass prerunner.

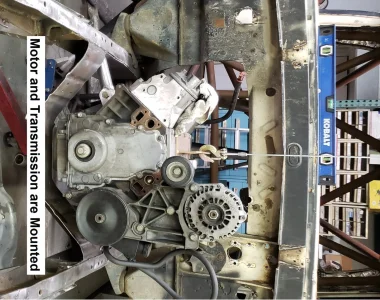

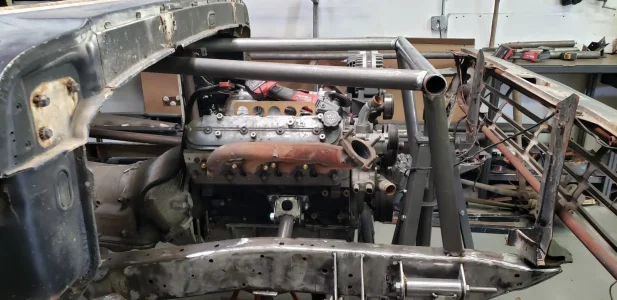

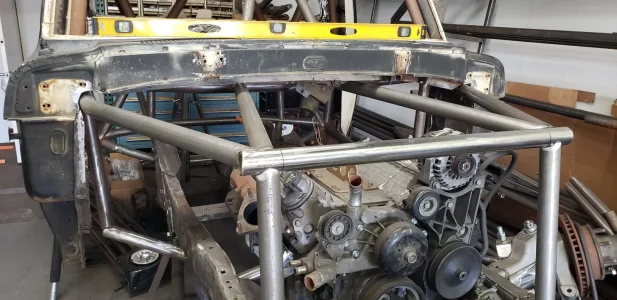

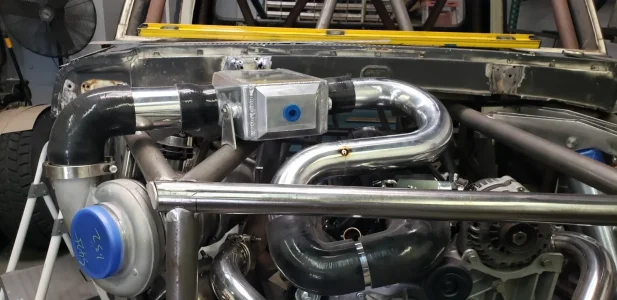

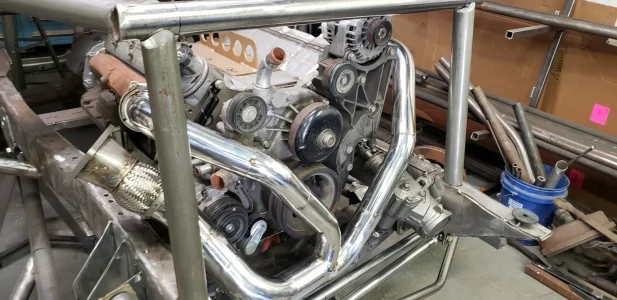

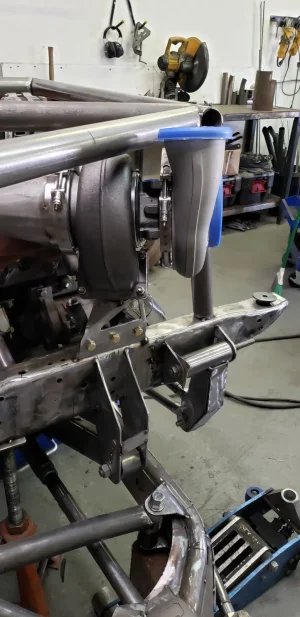

Going with a 6.0L LQ4 with forged bottom end since I'm running a single turbo on. 4L80e Trans and Ford NP205 T-case.

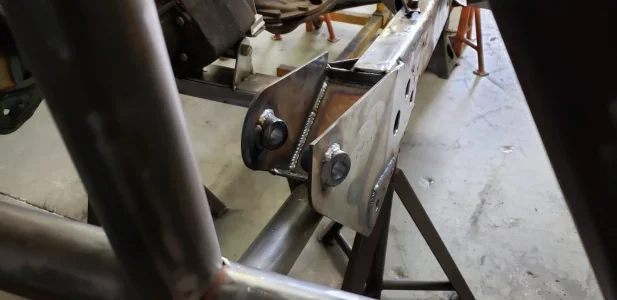

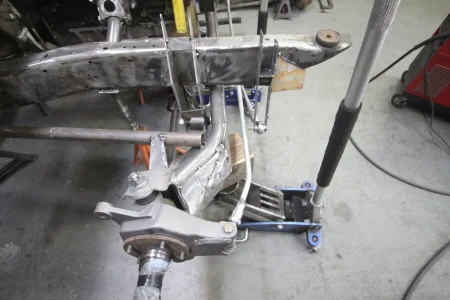

Equal length D50 TTB front end. Fox 3.0 coilovers and 3.5 bypasses and 2.0 air bump

Cab will be getting 3 seats across with middle PRP seat being slightly smaller and easily removable to make room for a nice cooler/Fridge to do in its place when going on a weekend trip with only 1 person, 3 seats will be for weekends in glamis and such to give more rides.

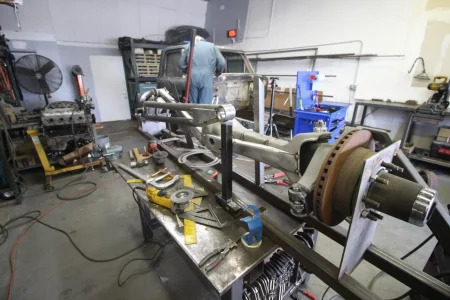

Rear is D70 Dually axle that is trussed and tabbed. D80 Spool with 37 spline chromo axle shafts. 5.13 gears since lowest gears I can run in the front end. 3.0 coilover and 4.4 Fox Bypass out back 2.5 air bump.

Most Likely going to run a different rear axle since the track width difference is quite a bit.

Trail Ready Beadlocks with BFG 40" tires

Single spare tire

Rear will also be running a Harmon Fuel Cell bladder in a custom can that I made. Approx 55 gallons

Cab will be getting all windows put back in along with a aftermarket Restomod AC system, heater and Stereo along with my Tablet mounted for GPS and Torque app when needed.

Mcqueen Front Fiberglass and Mcneil rear bedsides like the brodozer since i want to run stock tail lights as well.

Follow along with my instagram.com/tt.motorsports and my youtube since I'll be posting updated videos and photos on there as well as here.

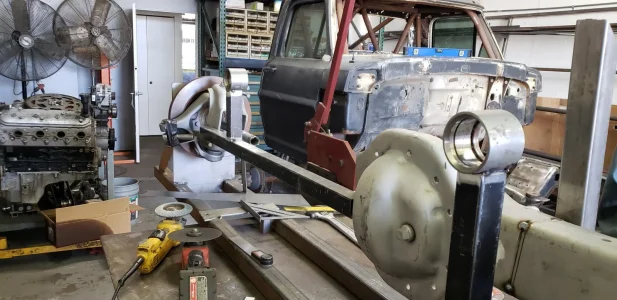

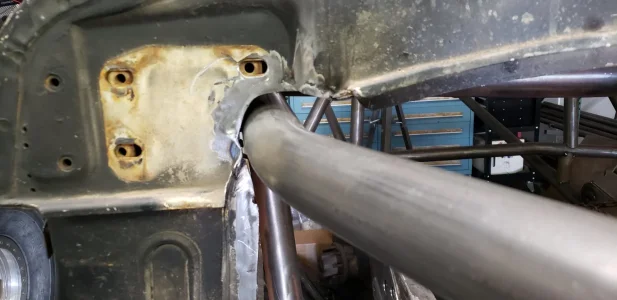

How it started. I got this truck in a trade as a "complete" prerunner that I parted out so essentially started with the registered pre smog truck for free. Started collecting parts and some of the fab work back in 2014. Worked on it for a couple years between jobs, stole some parts like trailing arms for my tacoma. Upgraded the coilovers from 2.5s to 3.0's but here's where the work started on it again after having it as a roller at my last shop in Santa Maria.

Ok so I have a 1968 Ford F250 that was previously a prerunner and I am rebuilding it into a 4x4 badass prerunner.

Going with a 6.0L LQ4 with forged bottom end since I'm running a single turbo on. 4L80e Trans and Ford NP205 T-case.

Equal length D50 TTB front end. Fox 3.0 coilovers and 3.5 bypasses and 2.0 air bump

Cab will be getting 3 seats across with middle PRP seat being slightly smaller and easily removable to make room for a nice cooler/Fridge to do in its place when going on a weekend trip with only 1 person, 3 seats will be for weekends in glamis and such to give more rides.

Rear is D70 Dually axle that is trussed and tabbed. D80 Spool with 37 spline chromo axle shafts. 5.13 gears since lowest gears I can run in the front end. 3.0 coilover and 4.4 Fox Bypass out back 2.5 air bump.

Most Likely going to run a different rear axle since the track width difference is quite a bit.

Trail Ready Beadlocks with BFG 40" tires

Single spare tire

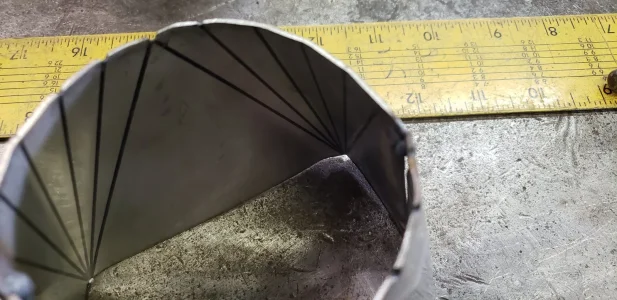

Rear will also be running a Harmon Fuel Cell bladder in a custom can that I made. Approx 55 gallons

Cab will be getting all windows put back in along with a aftermarket Restomod AC system, heater and Stereo along with my Tablet mounted for GPS and Torque app when needed.

Mcqueen Front Fiberglass and Mcneil rear bedsides like the brodozer since i want to run stock tail lights as well.

Follow along with my instagram.com/tt.motorsports and my youtube since I'll be posting updated videos and photos on there as well as here.

How it started. I got this truck in a trade as a "complete" prerunner that I parted out so essentially started with the registered pre smog truck for free. Started collecting parts and some of the fab work back in 2014. Worked on it for a couple years between jobs, stole some parts like trailing arms for my tacoma. Upgraded the coilovers from 2.5s to 3.0's but here's where the work started on it again after having it as a roller at my last shop in Santa Maria.