95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 139

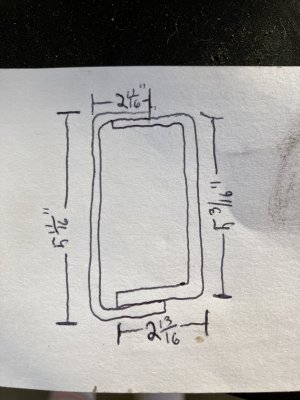

Any info on cutting and extending the beams on my bronco while keeping the solo radius arms I’m thinking cutting 1/4”-3/8” away from the threads on the side of the knuckle but need some help on best way to cut the beams straight and also have f someone can include the dimensions to make the extensions to match stock style plating would be great tried asking to buy some and even tried paying for some knowledge from Threat Motorsports and he got all pissy cause I’m trying to do the work on my own and not buy his full kit when I don’t need the full kit.

Yes I’m more than comfortable with attempting this and don’t want to go to a shop I can’t afford so just looking for tips and a little help.

Yes I’m more than comfortable with attempting this and don’t want to go to a shop I can’t afford so just looking for tips and a little help.