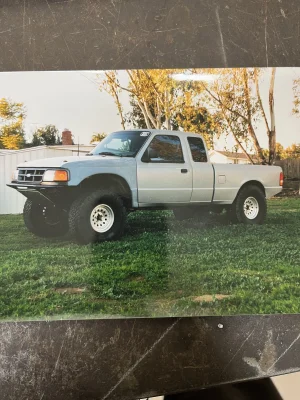

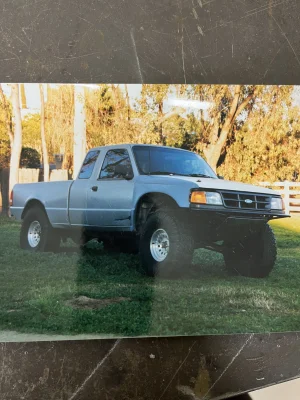

When you look at a bypass shock, it has compression tubes and rebound tubes to allow fluid to bypass the piston, depending on where these tubes are located on the shock bod, it will create a zone in which it controls via external adjustment. Smooth body shocks, you are limited to how how the compression and rebound stacks are built to control dampening. Ads has some good writes ups on shock in another thread on here. As was as shock placement for what you are building, i would suggest trying to get as close to perpendicular to the beam and radius arm at full bump and try to mount the shock as far out on the beam as reasonably possible, you will most likely encounter some challenges with the coil bucket in the stock location, but once you get in there and start building and cycling it, you will figure out where it needs to live. Like most builds, there will be compromises, just take your time and measure 2x- cut 1x