That looks slick as fuck! But… are you going to add some more side to side strength or are we just gonna commit a nun genocide?

Thanks Patrick! I'm trying to figure out where/how to incorporate a horizontal X across the frame rails. I think I can get one below the cooler (probably should have done that first lol), and I'm going to add a tube across the down tubes, just aft of the tool boxes. From there, I'll run tubes from the frame up to the center of that cross tube. Imagine like windshield ^ tubes. It's going to get a bumper and I'll try adding an x somewhere in there, and possibly an x in the gas tank cradle.

Edit: Looking at it now, I can throw an X between the tool boxes and cooler. It'll make getting the cooler in and out a pain, but will add a ton of strength.

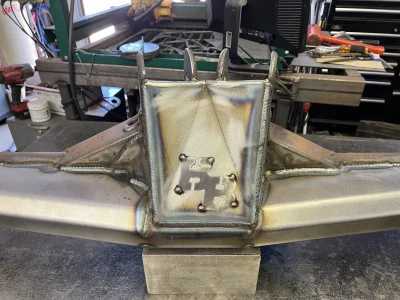

Here is where I finished off yesterday. Cooler and tool box tie down tabs welded on, limit straps tabbed up (I need the right hardware), and upper shock mounts boxed in.

Notice the shaved bump mount. I'm a loser and didn't droop the driver side all the way when bumping the passenger side during mock up, so the tire rubs a bit. Now it rubs a bit less. Even though I have a hydro bump, the coilover is still going to get a foam bump on the shaft, so hopefully that limits articulation a bit. Maybe a swaybar is in the future?

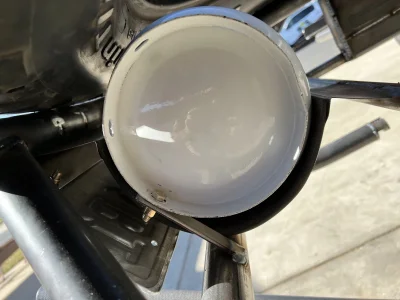

I keep going back and forth between flat and angled spare. I'm leaning towards flat...

All together

And how it's going to sit for a couple weeks.

Gotta pack and get everything squared away for our wedding/honeymoon!