@the bodj

Inner sleeve is .75 x 0.120wall 4130

White is 6-6 Nylon 1.0x0.120” wall tube from mcmaster

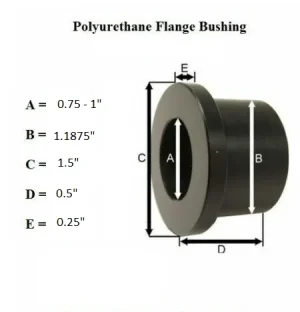

Black is soft urethane 2”ODx.5” wall tube from McMaster. I custom ground a tool to cut it—which is really difficult to hold tolerances because it’s soft and moves all over the place. I suggest grinding whilst spinning the soft urethane in the lathe. Cuts down on the bypass noise by around 70%. Dodah bought some bushings for this propose, IIRC. Shoot him a text, or I’ll ask that bastard if I see him at work.

These are for 3.0’s:

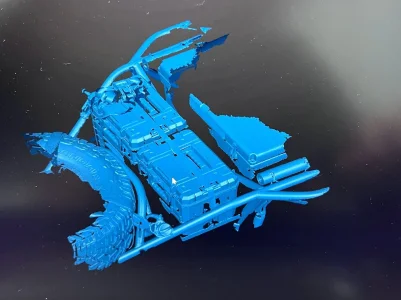

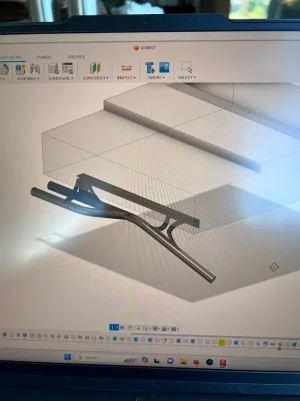

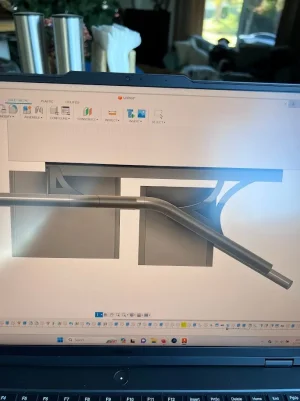

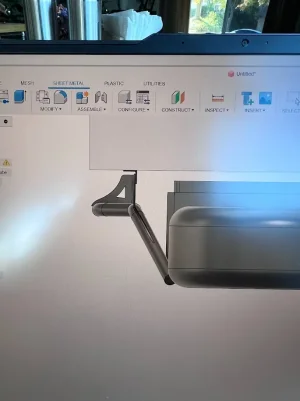

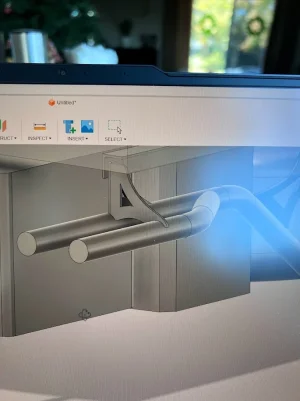

View attachment 17758View attachment 17759View attachment 17760View attachment 17761View attachment 17757