Figuring out a starting spring rate for your project can be difficult, even with corner weights of your vehicle it may be difficult to figure out what spring set up you should run, shock angle and position can all lead to a complicated trigonometry problem that will take half the day.

With a few simple measurements and formulas you can have great success, figuring out the corner force that your coil-over sees is not overly complicated but you will need a few items

1. tape measure

2. a jack that can lift the suspension into a full droop scenario

3. calculator or brush up on your long division

The first thing we need to do is determine the active spring rate that we have. For single rate that number is the rate of your spring as advertised by the manufacturer, for dual rate we use this formula to determine active rate, (upper rate x lower rate) / the sum of the upper and lower = active rate.

Example

10" 100lb/in upper

12" 200lb/in lower

(100x200)/300= 66.66666lbs/in

Secondly we need to know the free length of the springs, we can take this information either before installing them or from the manufacturers listings. Our example springs have a total combined length of (10" upper + 12" lower)=22". We will also need to know the thickness of our slider/spring divider in our example we will use .5" our total free length comes to (22" of spring+.5 slider)=22.5"

Ok now what? what do we do with this information?

We need to grab our tape measure and jack to figure out a few things, we need to know what our corner force is and we need to see how much droop and preload we have on our current set up. we can get all of this information with 2 measurements and simple math.

Step one

Measure the total length of your springs at ride height from top of top spring to bottom of bottom spring in our example we have 16.5"

Step two

Jack up the chassis of the vehicle and allow the suspension to fully droop out (leave your limit straps installed) our measurement comes out to 20.5"

Step three

Time for some math

To figure out our droop we take our ride height and subtract it by our full droop measurement 20.5-16.5=4. We have 4" of droop.

To figure out our preload we take our full droop and subtract if from our free length 22.5-20.5=2. We have 2" of preload.

To get our corner force number we take the preload plus the droop and multiply that by our active rate, (4+2)x66.6666666= (6)x66.6666666=399.99999

On our example vehicle we are using 399.99lbs/in to attain our ride height, Corner Force = 399.99lbs/in

What can we do with this number?

Now that we know how much energy or spring force it takes to hold up our chassis we can use this number to make changes without guessing what preload we need or combined rate.

"Generally" we like to set up vehicles with 2"-4" of preload this all depends on application and intended use and is greatly dictated buy the available springs and travel within the spring.

If you find that you have little to no, or even negative(loose) spring preload this formula will still help you get your springs corrected!

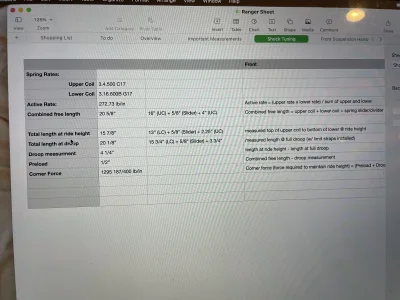

lets work on a messed up coil over set up on Dales Ranger

Dale has a beamed ranger that has less than stellar ride quality. He says his springs are loose and the truck seems overly rough. We had Dale take his measurements here is what he had

upper spring 14x400/lbin

lower spring 16x450/lbin

slider thickness .5"

= Total spring length 30.5" and 211.77lbin active rate.

Dale measured his ride height measurement at 27.5", when he measured his droop measurement the springs were very loose so we had him measure from the mating faces on his coil-over he got 32.5" that is -2" of preload, no good!

Lets finish our formula out

(Preload+Droop)x Active Rate = corner force (-2+5)x211.77= 3x211.77= 635.31 corner force

Dale likes his ride height and we agree that 5" of droop seems right for his application but the -2" of preload is not correct at all.

We know the corner force of his truck and we like our droop we just need to decide what preload we want, for Dale we want 2.5" of preload lets figure out what spring rate his truck wants.

lets take his droop add our desired preload and we can divide that by the corner force and it will give us our new desired combined spring rate.

635.31 corner force /(5" droop+ 2.5" of preload)/ = 635.31/7.5= 84.708.

Our new combined spring rate for 2.5" of preload and 5" of droop would be 84.708lbs/in ! Much different from the 211lb/in we had before.

If we use our formula from earlier we can play around with options of springs that get us to the 84.708 or we can call it 85lb/in to make things easy, a 150lb/in over 200lb/in looks almost perfect at (150x200)/350= 85.714. close enough for what we need!

I hope this little story helps out on getting your toys sprung correctly.

P.S.

Dale soon after cut his truck in half to start a back half project that he never finished, dont be like dale, run some preload and have fun out there your truck shouldnt be kicking your A**

We are doing some projects over here and i realized i left out all of you single rate guys and gals. here is the single rate method

Lets run this scenario on a single rate application and touch on a few common issues in these systems.

Bobbi, has an a-arm Tacoma with a Long travel kit on it, it runs a 8” long coil over with a single 16” 600lbin spring. Before she jacks up the vehicle she takes a measurement of the spring length at ride height. She measures 13”, when she droops out the suspension, the spring is measured again and we find 16”, this would mean there is 0” of preload on the spring, not good!

With our formula we can take our preload add it to our droop and then multiply it by the spring rate and get corner force.

(Preload + Droop) x Spring rate = Corner force

(0 + 3) x 600 = 1800lbs/in

Bobbi’s Tacoma has a front corner force of 1800lbs, she would like to get a spring with some preload in it to make the suspension a little more supple and active at droop for better traction.

Lets play with our formula and see what rate we can that allows for roughly 1-1.5” of preload we like the droop and will let that stay the same.

1800 / (Preload + Droop) = new rate

1800 / (1” + 3”) = 450lb/in

1800 / (1.5” + 3”) = 400lb/in

So it looks like we can just grab a 16” 400 or 450 and slap it on and run with our added preload right? Wrong! We need to check our spring travel and coil bind to see if these springs will work (short travel coilovers are a tricky balance between desired rate and available travel in the springs)

Lets check the spring travel numbers from Eibachs website, we find the following travel numbers listed for each spring

16 x 600lb/in 8.28” total travel

16 x 400lb/in 9.39” total travel

16 x 450lb/in 9.19” total travel

18 x 400lb/in 10.24" total travel

18 x 450lb/in 9.81” total travel

With the total travel numbers we can take our coil over travel and add it to our preload and see if we will coil bind or not, we need to have more travel in the coil spring than what is required for preload and shock travel.

16 x 600 spring

0 preload + 8” shock travel = 8” of spring travel required, we have 8.28” so we are good.

16 x 400 spring

1.5” Preload + 8” shock travel = 9.5” of spring travel required, we have 9.39” NO GOOD COIL BIND! This spring will not work for us

16 x 450 spring

1” preload + 8” shock travel = 9” of spring travel required, we have 9.19” this spring will work it has .19” more than we need so it will not coil bind, this margin is very little and will not allow for much adjustment if our measurements were slightly off.

So what should we do? Is Bobbi stuck with her 16 x 600 spring and no preload? We have the potential to run a longer spring with more spring travel in it and give her a bigger margin of error, allowing a lighter rate to be used. She has 1.5” of threads showing on her coil over body so there is room to move it up and, the spring rate she wants to run does require preload so it looks like it is possible to run an 18” spring. Lets check!

18 x 400 spring

1.5” preload + 8” shock travel = 9.5” of spring travel required, we have 10.24” we have .74” of spring travel left allowing for margin of error or future adjustment. This spring will work!

18 x 450 spring

1.0” preload + 8” of shock travel = 9” of spring travel required, we have 9.81” of spring travel this spring will work and has .81” of travel left over for future adjustment or margin of error more than our 18 x 400lb/in

Since Bobbi, is not running a bypass only a secondary bump stop we will sway her towards the 450lb/in to give a little more resistance at full bump.