You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Local Legend Project: Tur-BRO-yota

- Thread starter Turboyota

- Start date

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Moved the intercooler back toward the radiator. Intercooler mount will utilize McMaster 3/8" stud vibration damping mounts & Energy Suspension urethane bushings to support the top of the intercooler.

Machined a chamfer on the soft urethane bushings to clear the welds on the threaded spud on the intercooler.

Here's my upper mounting scheme with bushings and double studded rubber isolators:

The bottom will rest on 1/4" silicone sheet and will be bolted up through the front cross member with 5/16" bolts. I'll probably add red bushings on the bottom also. Notice the plate at the bottom of the intercooler is cracked at the mounting bung.

Tuned up the upper intercooler mounts. They need to be removable, so they will bolt to the radiator mounts.

Tiggered most of the mounting tabs & the front crossmember doubler plate.

Machined a chamfer on the soft urethane bushings to clear the welds on the threaded spud on the intercooler.

Here's my upper mounting scheme with bushings and double studded rubber isolators:

The bottom will rest on 1/4" silicone sheet and will be bolted up through the front cross member with 5/16" bolts. I'll probably add red bushings on the bottom also. Notice the plate at the bottom of the intercooler is cracked at the mounting bung.

Tuned up the upper intercooler mounts. They need to be removable, so they will bolt to the radiator mounts.

Tiggered most of the mounting tabs & the front crossmember doubler plate.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Total man-hours to date: 563

Total cost including parts & materials I had on-hand(4130 tube, bypasses, bumps, etc): $8789

Total length of tubing: 178 feet

Total weight of tubing added: 275 lbs

*(If all cagework was 1.75x0.120" wall, tube weight added would be 373 lbs)*

*(If all cagework was 2.0x0.120" wall, tube weight added would be 430 lbs)*

Total cost including parts & materials I had on-hand(4130 tube, bypasses, bumps, etc): $8789

Total length of tubing: 178 feet

Total weight of tubing added: 275 lbs

*(If all cagework was 1.75x0.120" wall, tube weight added would be 373 lbs)*

*(If all cagework was 2.0x0.120" wall, tube weight added would be 430 lbs)*

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Any of the DR bros remember the ¿What does the Turboyota weigh? Guessing game?

Everyone guessed the total weight and the front-to-back ratio.

Truck was weighed with a full tank of gas, 33x10.5 BFG Baja/alloy wheel spare, and the majority of the front bumper is included.

Everyone guessed the total weight and the front-to-back ratio.

Truck was weighed with a full tank of gas, 33x10.5 BFG Baja/alloy wheel spare, and the majority of the front bumper is included.

theycallmeWALLY

Administrator

- Joined

- Mar 30, 2022

- Messages

- 1,529

Can I help with the broken links? or is it from an old photobucket account or something?I joined months ago and my thread still has broken picture links. You're really putting me to shame.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Component weights:

Stock 5x4.5" Toyota hub with 12mm studs, 9.7x0.850" rotor, and bearings weight:

17.4lbs

Speedway Engineering 5x5.5" aluminum hub with 5/8" ARP studs, 2" ID Timken bearings, 12.19x.812" 160-5844Wilwood rotor, and rotor hat weight:

18.4 lbs

Splendid! Spectacular!

+1.0 lbs for all that badassery.

Wilwood 120-11131 Caliper and EBC brake pads weight:

6.4 lbs

Stock 5x4.5" Toyota hub with 12mm studs, 9.7x0.850" rotor, and bearings weight:

17.4lbs

Speedway Engineering 5x5.5" aluminum hub with 5/8" ARP studs, 2" ID Timken bearings, 12.19x.812" 160-5844Wilwood rotor, and rotor hat weight:

18.4 lbs

Splendid! Spectacular!

+1.0 lbs for all that badassery.

Wilwood 120-11131 Caliper and EBC brake pads weight:

6.4 lbs

Last edited:

charlie brown

Well-known member

- Joined

- Apr 4, 2022

- Messages

- 377

i did not know that FBC makes pads for willwood. whats the part numbers?

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

August 26 2017

Excellent quick shakedown dezert trip.

motiracer(Beaumont) and I did 84.3 dirt miles over two days

The Turboyota handled good! I'm stoked on the initial shock & bumpstop setup.

Heading down toward soggy dry lake from the rockpile, Beaumont and I both hit around 80MPH on the racecourse.

Drove the truck onto the trailer--Great success!

Excellent quick shakedown dezert trip.

motiracer(Beaumont) and I did 84.3 dirt miles over two days

The Turboyota handled good! I'm stoked on the initial shock & bumpstop setup.

Heading down toward soggy dry lake from the rockpile, Beaumont and I both hit around 80MPH on the racecourse.

Drove the truck onto the trailer--Great success!

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

September 11, 2017

Scrap tube cattle guard bumper fab:

Bumper is made from scrap tubes and mockup tubes. Rolled tubes are 1.75x0.090" welded seam, verticals are 1.75x0.120" 4130. Top & bottom frame horn plates are 3/16x2" bar, frame horn sides are 1/8" P&O.

Skid plate tubes are laid out with blue tape.

Scrap tube cattle guard bumper fab:

Bumper is made from scrap tubes and mockup tubes. Rolled tubes are 1.75x0.090" welded seam, verticals are 1.75x0.120" 4130. Top & bottom frame horn plates are 3/16x2" bar, frame horn sides are 1/8" P&O.

Skid plate tubes are laid out with blue tape.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

October 5, 2017

Passenger inner frame horn plate has a joggle in it to clear the intercooler. (The intercooler is shifted slightly towards the passenger side.)

Added 1.5x0.120" 4130 skid plate support tubes:

Skid plate material: 0.125" 7075 aluminum.

I cut the aluminum sheet with my wifey's "crafting" jigsaw because the dickhead former 1/2 owner of the truck borrowed my badass $150 DeWalt jigsaw and never returned it. Fucker. I had to use that shitty $30 Craftsman jigsaw--like a brokedick poverty line asshole. Fuck.

Installed the swapmeet-sourced Mastercraft belts:

Lap belts attach a little behind the rear seat mount tab. The 7/16-20 eyelets are attached through the 1.25"x0.065" 4130 rear seat tubes.

Crotch strap is bolted through the floor with 3" washers.

I attached my bitchin' 1980's Con Ferr roof rack to the rear of the truck.

Turned a couple tube clamps from 2.0x0.120" DOM that will be affixed with hose clamps. Reliefs are so the hose clamps sit flush with OD of the tube. Halved it on the bandsaw.

Welded the tube clamps to the rack, and drilled/through-bolted to the rear cagework.

The 30-year-old Con Ferr rack is beefy enough to hold my 260# large mammal ass!

Also, it's the perfect size for two camping chairs at the races. It will still unbolt and attach to the back of my racetruck with 4X 3/8" bolts in a jiffy.

Front bumper & skidplate fab time: 17.5 hrs

80's Con Ferr rack install: 1.5 hrs

Mastercraft 5pt belt install: 1.5hrs

Passenger inner frame horn plate has a joggle in it to clear the intercooler. (The intercooler is shifted slightly towards the passenger side.)

Added 1.5x0.120" 4130 skid plate support tubes:

Skid plate material: 0.125" 7075 aluminum.

I cut the aluminum sheet with my wifey's "crafting" jigsaw because the dickhead former 1/2 owner of the truck borrowed my badass $150 DeWalt jigsaw and never returned it. Fucker. I had to use that shitty $30 Craftsman jigsaw--like a brokedick poverty line asshole. Fuck.

Installed the swapmeet-sourced Mastercraft belts:

Lap belts attach a little behind the rear seat mount tab. The 7/16-20 eyelets are attached through the 1.25"x0.065" 4130 rear seat tubes.

Crotch strap is bolted through the floor with 3" washers.

I attached my bitchin' 1980's Con Ferr roof rack to the rear of the truck.

Turned a couple tube clamps from 2.0x0.120" DOM that will be affixed with hose clamps. Reliefs are so the hose clamps sit flush with OD of the tube. Halved it on the bandsaw.

Welded the tube clamps to the rack, and drilled/through-bolted to the rear cagework.

The 30-year-old Con Ferr rack is beefy enough to hold my 260# large mammal ass!

Also, it's the perfect size for two camping chairs at the races. It will still unbolt and attach to the back of my racetruck with 4X 3/8" bolts in a jiffy.

Front bumper & skidplate fab time: 17.5 hrs

80's Con Ferr rack install: 1.5 hrs

Mastercraft 5pt belt install: 1.5hrs

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

October 9, 2017

Fuck that steering.

Started with 1.25x0.25" wall 4130 tube. Drilled one end 13/16" and tapped 7/8"-14.

Notched the other end

Machined the bushing sleeve from 1.25x0.188wall 4130

Machined the bronze bushings. Sourced from McMaster Carr.

Bushing assembly that will be on the idler arm side:

Centerlink almost ready for tack welding. Tierods pivots to follow.

Time: 1.5 hrs

Cost: 7/8 muffpuff rodend $20; bushings from McMaster SAE 660 leaded tin bronze part number: 7815K44, $6.36 each

Therefore: total cost $32.72

Had all the 4130 tube on-hand

Alcohol consumption: 1/3 bottle of Stoli

Fuck that steering.

Started with 1.25x0.25" wall 4130 tube. Drilled one end 13/16" and tapped 7/8"-14.

Notched the other end

Machined the bushing sleeve from 1.25x0.188wall 4130

Machined the bronze bushings. Sourced from McMaster Carr.

Bushing assembly that will be on the idler arm side:

Centerlink almost ready for tack welding. Tierods pivots to follow.

Time: 1.5 hrs

Cost: 7/8 muffpuff rodend $20; bushings from McMaster SAE 660 leaded tin bronze part number: 7815K44, $6.36 each

Therefore: total cost $32.72

Had all the 4130 tube on-hand

Alcohol consumption: 1/3 bottle of Stoli

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

October 23, 2017

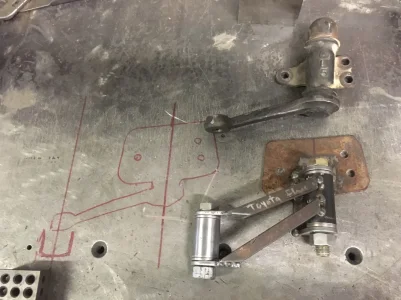

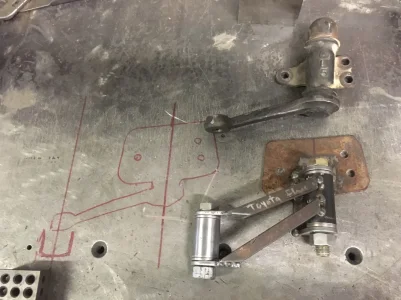

Idler arm mock-up & complete:

Moved the inner tierod pivots around on the centerlink to gain clearance and reduce bumpsteer. I'm still getting some toe-in at full droop.

Since I used a 7/8 heim at the pitman arm, I had to machine clearance into the driver's-side tierod.

I had to space up the outer tierod pivot a LOT to try to reduce bumpsteer. I'll probably tune it up a little more before finalizing the inner tierod pivot location.

Idler arm mock-up & complete:

Moved the inner tierod pivots around on the centerlink to gain clearance and reduce bumpsteer. I'm still getting some toe-in at full droop.

Since I used a 7/8 heim at the pitman arm, I had to machine clearance into the driver's-side tierod.

I had to space up the outer tierod pivot a LOT to try to reduce bumpsteer. I'll probably tune it up a little more before finalizing the inner tierod pivot location.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Dec 2017

Clearanced the lower arm for the pitman arm interference at full bump.

Music: Metallica—Ride the Lightning

Drinks: 4oz Coldcock herbal whiskey

Tools: 4.5” grinder with cutoff wheel and flap wheel. Tig welder. Mig welder for tack welds

Materials: 1/8” steel plate from the scrap bin,

Self etching primer

Current lower a-arm weight: 16lbs 4.8oz

Stock centerlink weight: 7lbs 10.6oz

New centerlink weight: 8lbs 6oz

New longer Tierods weigh: 7lbs 15.6oz

And I primed & painted the centerlink and pitman arm.

Clearanced the lower arm for the pitman arm interference at full bump.

Music: Metallica—Ride the Lightning

Drinks: 4oz Coldcock herbal whiskey

Tools: 4.5” grinder with cutoff wheel and flap wheel. Tig welder. Mig welder for tack welds

Materials: 1/8” steel plate from the scrap bin,

Self etching primer

Current lower a-arm weight: 16lbs 4.8oz

Stock centerlink weight: 7lbs 10.6oz

New centerlink weight: 8lbs 6oz

New longer Tierods weigh: 7lbs 15.6oz

And I primed & painted the centerlink and pitman arm.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

Hours for all the aforementioned completed tasks:

Upper front shocks mounts: 26 hrs

Front cagework(firewall forward): 41 hrs

Mount grill, headlights, & fiberglass: 13 hrs

Mount engine accessories on engine cage: 11.5 hrs

Front bumper: 13.5 hrs

All new steering: 33 hrs

Upper front shocks mounts: 26 hrs

Front cagework(firewall forward): 41 hrs

Mount grill, headlights, & fiberglass: 13 hrs

Mount engine accessories on engine cage: 11.5 hrs

Front bumper: 13.5 hrs

All new steering: 33 hrs

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 17

- Views

- 1K

- Replies

- 13

- Views

- 1K