You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Local Legend Not much left Tacoma left... 4500 koh build

- Thread starter Hambone

- Start date

the bodj

Well-known member

looks lke if you bend the top of the a-pillar some more it might tuck a little tighter/better

If he did that he'd have to raise the whole tube up, which would bring the lower windshield bend too high and probably hit the windshield. I'd leave it. It's a little low for getting in the truck, but makes for more room above your head when seated. My truck is set up similarly.

I’m afriad of wasting more tube if I over bend etc. I wish it was a little higher and it may end up slightly higher but it’s just about tucked into the body where I cut all the supports out so should leave plenty of head room. I added a c pillar and pushed up on the main tube and that helped some as well.looks lke if you bend the top of the a-pillar some more it might tuck a little tighter/better

I did some stuff for a buddy and some house projects so only got the c pillar done today and now I’m out of tubing. I’ll pick up some more this week after work and continue on the cage next week. Also slapped the headers on just cause and the driver clears but passenger v band gets into the motor mount. May have to find a different set.

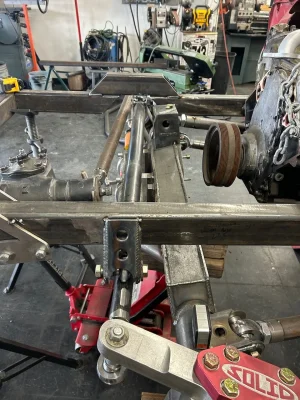

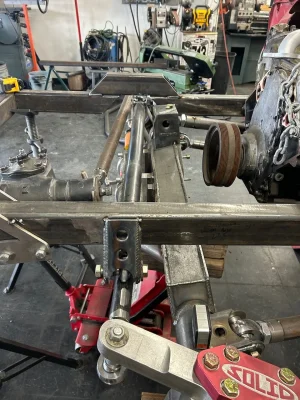

Was just going to have a lazy day but reading forums and looking at pictures decided to go out and mess with the panhard for a little bit. I’ve been putting off adding bends to the panhard and ended up adding (2) 12 degree bends on either side where the ram ends as at full bump the panhard hits the ram. I then notched the passenger side from for the panhard bracket to go into and draglink to go into. Regret putting it off as it worked well and now everything clears. 12 degrees may have been a little much and I can probably get away with 6-10 which I’ll try later. But this will allow me to lower the axle side panhard some as well so it’s not a giant lever. The draglink just barely gets into the bolts on the ram so I either need to move the steering box forward a 1/4-1/2 inch or add a bend. Not sure adding a bend will solve my issue but I may try it just to see.

And the upper link ends up getting into the headers so I’ll have to do something about that.

What’s everyone’s thoughts on offsetting the frame side panhard mount back as right now my limiting factor is the frame side panhard heim is hitting the tie rod.

And the upper link ends up getting into the headers so I’ll have to do something about that.

What’s everyone’s thoughts on offsetting the frame side panhard mount back as right now my limiting factor is the frame side panhard heim is hitting the tie rod.

Picked up more dom and got the c pillar knocked out and made a dash bar. Posted some pictures on Instagram and had a guy message me asking what happened if I swapped the a pillars side to side to minimize the gap between the sheet metal. I ended up doing it and made a big difference. Good chance I got them mixed up when I had them out last so I swapped them and made a big difference. Ended up tacking them back in after swapping them but need to make a new dash bar.

I think I’m over complicating the cage with to many bends. I have plans probably after the roof and b and c pillars get beat to cut them off and maybe even just run a hood and fenders and bedsides. So to simplify the cage, try to do a flat roof “x” and minimal bends so it doesn’t look goofy with the roof off.

I also got a set of prp seats my parents got me for Christmas a few years ago installed in the other crawler. Think they turned out good. Just waiting on harnesses. The harness bar is against the rear wall under the window.

First picture is before. 2nd picture is after.

I think I’m over complicating the cage with to many bends. I have plans probably after the roof and b and c pillars get beat to cut them off and maybe even just run a hood and fenders and bedsides. So to simplify the cage, try to do a flat roof “x” and minimal bends so it doesn’t look goofy with the roof off.

I also got a set of prp seats my parents got me for Christmas a few years ago installed in the other crawler. Think they turned out good. Just waiting on harnesses. The harness bar is against the rear wall under the window.

First picture is before. 2nd picture is after.

the bodj

Well-known member

Those look almost just like @Exploder_M seats haha

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

I think every tube on my roof is bent but being tall I needed every inch I could get. The pillars look good, the only way I have found to get them tighter is to tie into the top of a dash bar. There's probably a few pictures in my build thread if you're curious. The panhard on my Sequoia ended up with more bends than yours and only time will tell if it'll hold up. Tight packaging to maximize up travel for sure.

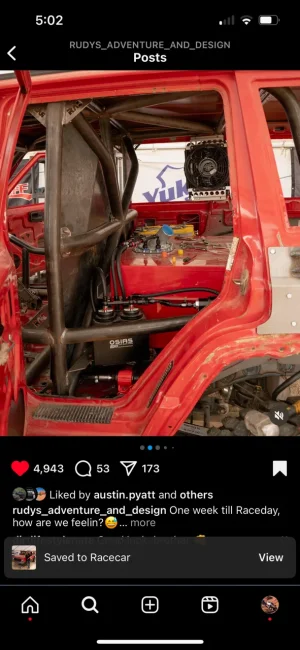

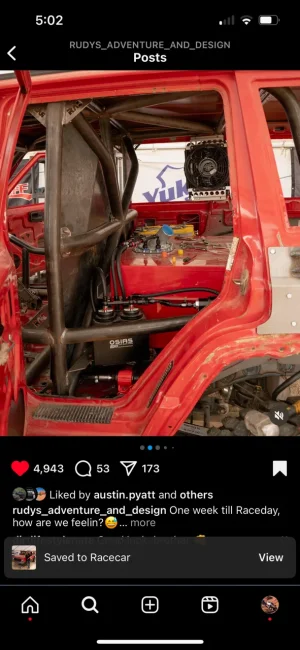

Spent the last 2 days messing with the cage. Wasn’t planning to add as many bends to the roof bars but it was needed to get the headroom and still be able to see. Still need to do one more bar down the middle in the back and the intrusion bars but I’ll wait till I screw up something and have some waste.

Next I want to get the seats mounted so I can do the b pillar. Plan is to run a bar between the an and b pillar and then run some tubes towards the trans but stop them short with some supports off the subframe. The trans needs to come out of the door so trying to make it easy ish to get out. Was originally going run tubes over the trans and atlas but my dad suggested just stopping them short.

Also ordered rhe shocks.. think I’ll order a rear housing so I can start on that while I wait for the shocks.

Next I want to get the seats mounted so I can do the b pillar. Plan is to run a bar between the an and b pillar and then run some tubes towards the trans but stop them short with some supports off the subframe. The trans needs to come out of the door so trying to make it easy ish to get out. Was originally going run tubes over the trans and atlas but my dad suggested just stopping them short.

Also ordered rhe shocks.. think I’ll order a rear housing so I can start on that while I wait for the shocks.

Couple questions as I need to order a bunch of parts so I’ll do a few different posts.

First question is gearing/atlas ratio.

Pretty set on 5.43 axle gears and a 3.0:1 atlas but still considering a 3.8:1. Goal obviously is to race koh and a few races here and there depending on funds but truck will also just be a rock crawler etc. 5.3/th350 and 37 on tires. 28-3000 stall.

Crawl ratios:

3.0/5.43-41

3.8/5.43-52

3.0/5.13-38

3.8/5.13-49

I’m pretty set on the 3.0 and 5.43s but considering the 3.8 and 5.13s. Any real world input on the ratios? A 4 speed is out of the budget. Is a 40 crawl ratio to high for “technical” stuff at sand hollow and moab and jv but is 52 to low for racing? Is there even enough difference I’ll notice it.

First question is gearing/atlas ratio.

Pretty set on 5.43 axle gears and a 3.0:1 atlas but still considering a 3.8:1. Goal obviously is to race koh and a few races here and there depending on funds but truck will also just be a rock crawler etc. 5.3/th350 and 37 on tires. 28-3000 stall.

Crawl ratios:

3.0/5.43-41

3.8/5.43-52

3.0/5.13-38

3.8/5.13-49

I’m pretty set on the 3.0 and 5.43s but considering the 3.8 and 5.13s. Any real world input on the ratios? A 4 speed is out of the budget. Is a 40 crawl ratio to high for “technical” stuff at sand hollow and moab and jv but is 52 to low for racing? Is there even enough difference I’ll notice it.

Next question is on the engine.

It’s just a gen 3 5.3. Plan is stock bottom end. Stock crank/rods/pistons. New bearings and rings.

Plan is to buy a set of heads from summit racing. But open to suggestions CHEVROLET Chevy small block Gen III/IV (LS-based engines) Summit Racing Cylinder Heads Cylinder Heads Engines & Components - Free Shipping on Orders Over $109 at Summit Racing

I bought a comp cam nsr drift cam 233/243 without knowing much if anything about cams (and still don’t) along with a set of springs (both linked below).

Cam

www.compcams.com

www.compcams.com

Springs

www.compcams.com

www.compcams.com

Is this a decent setup? Goal isn’t crazy high hp. Just something reliable that’ll scoot through the desert. I know some of the summit heads come with springs so I wouldn’t need the ones I bought but could always sell them. Is this a cam I should be running?

I was going to run a ls3 intake for clearance reasons and probably a 92mm throttle body. An aeromotive regulator with return port. (Recommendations?)

This fuel pump with a spare plumbed side by side

www.kartek.com

www.kartek.com

Plan is this kevko oil pan as it’s about the same price as buying a cast pan and adding a baffle system but same thing. Open to ideas.

kevkoracing.com

What returnless fuel rails are recommended?

What lifters? Anything else I’m missing?

I have very limited knowledge as I’ve never built an ls before and the information is a little overwhelming.

It’s just a gen 3 5.3. Plan is stock bottom end. Stock crank/rods/pistons. New bearings and rings.

Plan is to buy a set of heads from summit racing. But open to suggestions CHEVROLET Chevy small block Gen III/IV (LS-based engines) Summit Racing Cylinder Heads Cylinder Heads Engines & Components - Free Shipping on Orders Over $109 at Summit Racing

I bought a comp cam nsr drift cam 233/243 without knowing much if anything about cams (and still don’t) along with a set of springs (both linked below).

Cam

NSR Drift 233/243 Hydraulic Roller Cam for GM LS GEN III/IV

The NSR (No Springs Required) Drift Cam for GM 4.8-5.7 LS is a drop in camshaft upgrade designed to wake up smaller displacement LS's and provide a wide, usable power increase for the grassroots enthusiast.Springs

0.559" Max Lift LS6+ Beehive Valve Spring Kit w/ Chromemoly Steel Retainers

The COMP Cams® .559" Lift Beehive™ LS6+ Valve Springs are now available in complete valve spring kits that allow for easy installation on popular LS applications.Is this a decent setup? Goal isn’t crazy high hp. Just something reliable that’ll scoot through the desert. I know some of the summit heads come with springs so I wouldn’t need the ones I bought but could always sell them. Is this a cam I should be running?

I was going to run a ls3 intake for clearance reasons and probably a 92mm throttle body. An aeromotive regulator with return port. (Recommendations?)

This fuel pump with a spare plumbed side by side

Pierburg 7.21659.72.0 Insulated Electric Fuel Injection Fuel Pump 5/8" Inlet 10mm-1.0 Outlet On Top - Kartek Off-Road

Pierburg 7.21659.72.0 Insulated Electric Fuel Injection Fuel Pump 5/8" Inlet 10mm-1.0 Outlet On Top for offroad racing in the King of the Hammers, New Zealand Taupo 1000, Dakar Rally, Tatts Finke Desert Race, Score International Baja 500 or Baja 1000, Mint 400, Vegas to Reno, Silk Way Rally...Plan is this kevko oil pan as it’s about the same price as buying a cast pan and adding a baffle system but same thing. Open to ideas.

LS1002 F-BodyOff Road/Road Race 5

Pan Depth: 5"Pan Capacity: 6 Quarts (5.7 Liters)System Capacity: 7 Quarts (6.6 Liters)Description: 11" Long, 8-3/8" Wide, 5" Deep Rear Sump. 1-3/4" Front Depth. Designed for the F-Body but primarily used in the Off-Road Racing world. Features a Diamond gate design that forces oil through the...kevkoracing.com

What returnless fuel rails are recommended?

What lifters? Anything else I’m missing?

I have very limited knowledge as I’ve never built an ls before and the information is a little overwhelming.

And the last question is reference the high pinion front 3rd. Same thing. Excuse my ignorance as I’ve never done a hp or really any gears before but my dad has done some gear installs.

I have the case from gw and a Yukon zip locker. I know the case will need to be clearanced some for the zip and I’ll order the gears from gw but do I just use a regular 9” install kit? This is everything I think I need from the gw website but I’m not entirely sure. I emailed them and left a voicemail just waiting to hear back.

Parts I think I need:

1350 yoke

10” pinion support (can I use any pinion support or is theirs the better one to use)

Pinion shim set

35 spline pinion nut

3.250 Carrier bearing set

Load bolt

35 spline pinion bearing set

Ring gear bolts

Gears

Am I missing anything? And is there an install kit I can get from east coast gear supply or Yukon?

I have the case from gw and a Yukon zip locker. I know the case will need to be clearanced some for the zip and I’ll order the gears from gw but do I just use a regular 9” install kit? This is everything I think I need from the gw website but I’m not entirely sure. I emailed them and left a voicemail just waiting to hear back.

Parts I think I need:

1350 yoke

10” pinion support (can I use any pinion support or is theirs the better one to use)

Pinion shim set

35 spline pinion nut

3.250 Carrier bearing set

Load bolt

35 spline pinion bearing set

Ring gear bolts

Gears

Am I missing anything? And is there an install kit I can get from east coast gear supply or Yukon?

That’s what I’m learning and doesn’t really produce any power till 3500 rpm so I’ll be looking for new one I think.seems like that cam is more designed for revs, not torque? The graph shows it losing torque compared to stock from 3500-4500

Seat mounts have been kicking my ass. Sadly this took me two days and still not done. Trying to find something functional, looks good and allows my head to clear the cage has been a challenge but think I finally got it. Literally as low as they can go with the atlas. Should have maybe lowered the subframe some more but it’s done.

Redid the seat mounts after a suggestion on irate

Alright redid the seat mounts again. Got them a little lower by another inch or so and moved the one bar between the b pillar. So the entire seat mount is out of 1x.120 wall dom and 3/16 tabs. Between the seat cushion settling some (I’ve been told it’ll settle between 2-3”) and the harnesses pulling you into the seat. Should be more than enough room. Not really interested in going to composite Seats for now.

Alright redid the seat mounts again. Got them a little lower by another inch or so and moved the one bar between the b pillar. So the entire seat mount is out of 1x.120 wall dom and 3/16 tabs. Between the seat cushion settling some (I’ve been told it’ll settle between 2-3”) and the harnesses pulling you into the seat. Should be more than enough room. Not really interested in going to composite Seats for now.

Then messed with starting on the b pillar x. Was able to salvage the original cross bar I made by adding another 15 degree bend on each side. It probably only needed 10-12 degrees but the extra between the seat and bar will make getting to harnesses and any bags I put between easier. I got the top two bars of the x in as well. They look close but are no where near your head. Even if you got whiplash, your head won’t hit the bars because of the head rest. I may order the seats with +2 in height to just get the head rest a little higher. Pretty much copied this Cherokee build for the b pillar

Similar threads

- Replies

- 10

- Views

- 246

- Replies

- 10

- Views

- 1K

- Replies

- 0

- Views

- 472