No. Plan is have it done summer 2025 and race is 2026this things gunna be cool! You trying to race this thing this year?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Local Legend Not much left Tacoma left... 4500 koh build

- Thread starter Hambone

- Start date

oddball23

Active member

Looks like a blast. Just 1 piece at a time

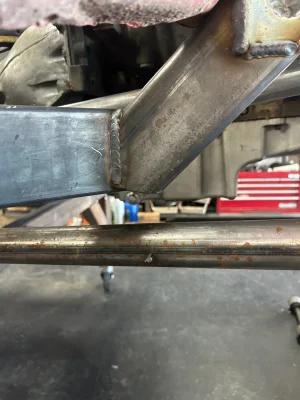

I could. Was just trying to keep the tabs out of the middle of the node for no real reason. I’ll either shorten the tabs or just box them in.yea, bent tabs look funky. Seems like you could just run them straight down to tube, no?

Cut a big pile of tabs today and got the axle side lower link tabs welded and got the axle side upper link tacd together. Ended up cutting the housing down but left it about an 1.5 long till I get hubs to measure exactly what it needs cut down too. I put the cs where I think they will end up and got the link mounts tacd to the frame and axle. Pretty happy with everything so far. Front links are looking like 33.5. I was wanting 36 ish so I’ll probably push the axle the 2.5 inches forward to where I want it.

Cut some tabs and made some hub tools for a few guys. Also got the mock up links cut and tacd and then got the tube I’ll mount the upper link off of cut and notched. It took forever with the 45 degree cut at the frame and 4 intersecting tubes to notch around at the bottom. But should work well.

Also made a magnetic grinding table to help hold tabs and clean them.

Also made a magnetic grinding table to help hold tabs and clean them.

Got the upper link tacd in place. Drilled a 1.5 hole in the tube for a sleeve and then built a bracket to make it double shear. Itll all get covered in gussets and supports. Wasn’t till I got it all tacd up I realized I need a 7 in bolt but would only fit it I dropped the trans or sleeved the frame. So ordered a piece of chromoly rod I’ll turn down and tap for 5/8-18 threads and use the longest bolt I can fit in there.

The first set of pictures are how I had it at first and after staring at it, I didn’t like the way the bracket was sitting so ground and bent some more to get the heim in the center of its travel.

The first set of pictures are how I had it at first and after staring at it, I didn’t like the way the bracket was sitting so ground and bent some more to get the heim in the center of its travel.

Put the axle at full bump and the upper link hits the motor mount so that will have to get redone. Currently it has 6 inches of uptravel. The lower links will hit the frame in an 1.5 and the housing will hit in 2.5. So I’ll change the motor mount and then probably cut the bottom of the frame to get the housing to bottom out on the frame. Shooting for 7.5-8inches of uptravel.

When I picked up the steering servo from a guy on Instagram. He gave me a few steering boxes. One was a depowered Saginaw box that was missing the sector shaft and the other was a complete box. So I took the complete one apart and put the sector shaft in the depowered one and made a template to cut a frame plate. I’ll order a rebuild kit and do the depowered box just to make sure it’s good and if I can find another sector shaft I’ll build the second as a spare.

And the trans tabs being bent bothered me so I remade them.

And the trans tabs being bent bothered me so I remade them.

Not necessarily. I need the vertical separation between the upper and the lower at the axle end. I wanted 8-10 inches of separation and it’s 8.5 right now. It’s horizontal just because it’s a file I bought from diy offroad. As long as I don’t run out of misalignment I’ll leave it. If not I’ll recur the side pieces and run it the oppositeSeems like that horizontally mounted rod end for 3 link is making the up travel harder to achieve for sure...

dwphoto

Administrator

Good work dude. Needs a Badlines sponsor door sticker  . DM me your add I’ll mail ya some

. DM me your add I’ll mail ya some

Thanks man. I keep meaning to order a trash sack and some stickers but marketplace deals keep taking my money lolGood work dude. Needs a Badlines sponsor door sticker. DM me your add I’ll mail ya some

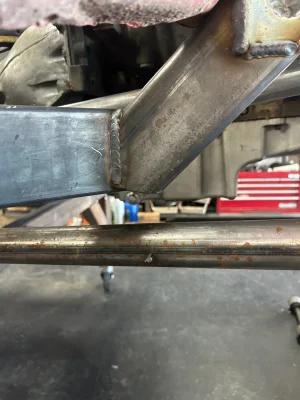

Spent yesterday getting the housing cut really close to length. Won’t know if it’s correct till I order spindles and hubs. I tried putting the solid axle industry cs on. Used a hone to clean them up some and heated them in the grill and sanded the tube. Same way I did my last axle but something was off and they wouldn’t go on. One got stuck and I beat the shir out of it to get it back off and called it a night.

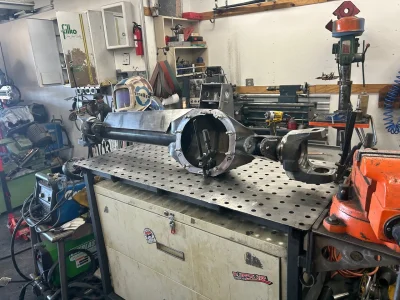

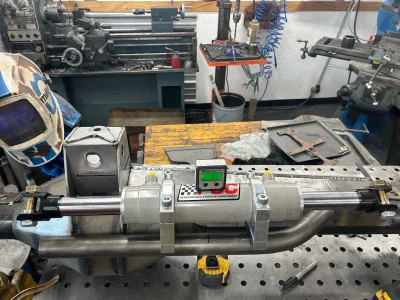

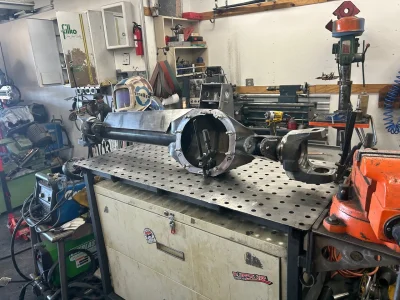

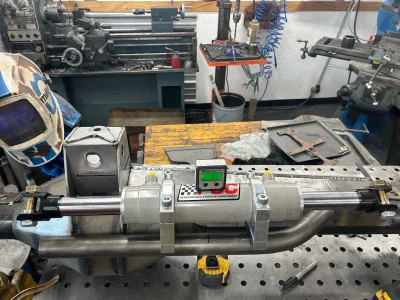

Today I just threw them in the mill and spent the time to get the boring bar centered and a single pass made it so they slip on with the tap of a hammer. This let me assemble the inner c and get the knuckle on so I can start to figure out the steering ram. Need the steering ram on so I can figure out the panhard and get the steering box in place before I throw it back under the truck.

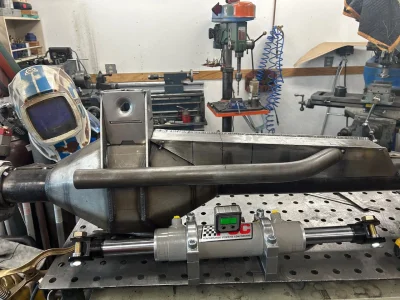

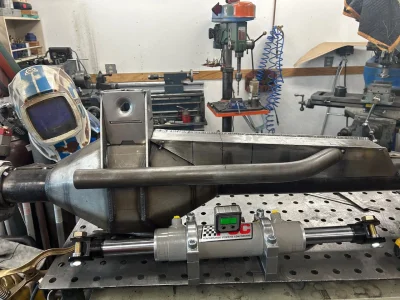

This was what I started with to mount the ram. Just a piece of 1.75 bent at a 45. I didn’t like the ram hanging over the front and how high it was.

Today I just threw them in the mill and spent the time to get the boring bar centered and a single pass made it so they slip on with the tap of a hammer. This let me assemble the inner c and get the knuckle on so I can start to figure out the steering ram. Need the steering ram on so I can figure out the panhard and get the steering box in place before I throw it back under the truck.

This was what I started with to mount the ram. Just a piece of 1.75 bent at a 45. I didn’t like the ram hanging over the front and how high it was.

Similar threads

- Replies

- 10

- Views

- 246

- Replies

- 10

- Views

- 1K

- Replies

- 0

- Views

- 472