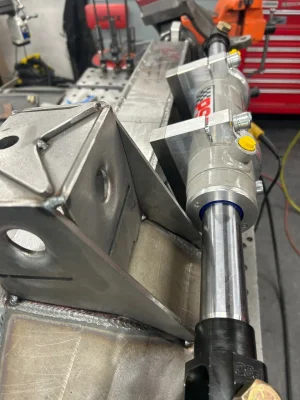

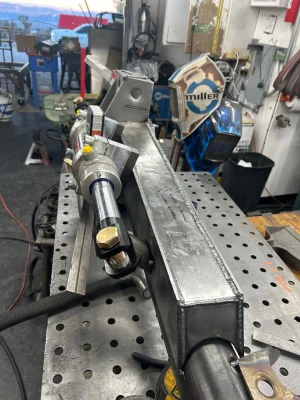

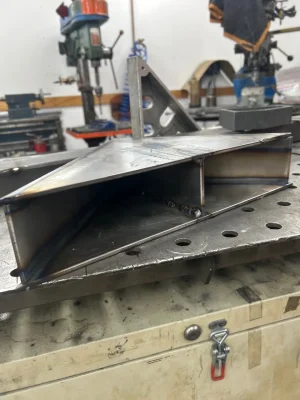

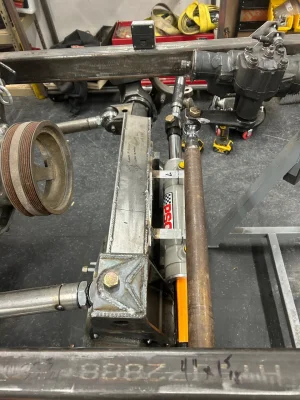

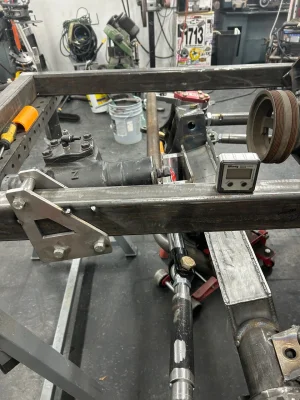

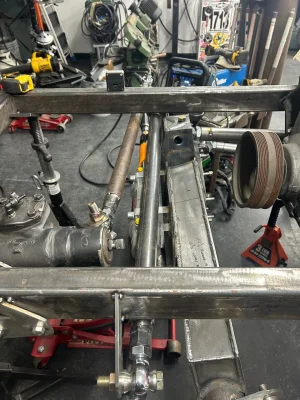

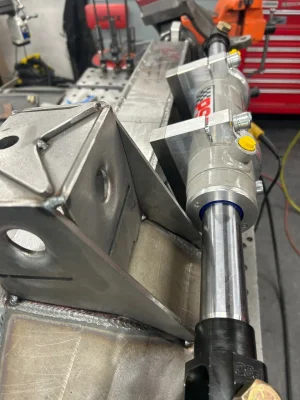

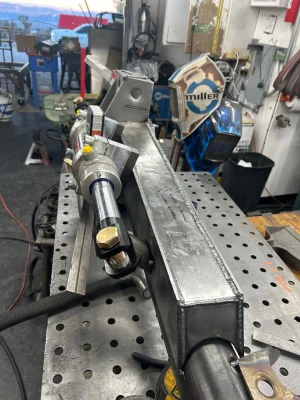

So I notched the tube around the center section and lowered it some and placed the ram at an angle. I honestly have no idea what I’m doing just using some pictures as a reference. Tomorrow I’ll measure how much steering I have on my other truck as it’s identical besides the knuckles on it are stock dodge ones. But that’ll give me an idea of how much steering I’ll get and if I need to move the ram closer to the housing to get the shaft inline at full steer.

If anyone has any input I’m all ears. I’ve never set up a double ended ram before.

If anyone has any input I’m all ears. I’ve never set up a double ended ram before.