Got the driver side door bars done a couple weeks ago and welded everything up then painted the new tube work

Then on Friday I buttoned the whole truck back up and brought it out of the garage for the first time in months and cleaned it up. Took it down to cars and coffee to meet a buddy Saturday morning down there. Even brought the kid.

Now this is the part I’m hoping to get some ideas from you guys. After driving the truck back home about 30 miles or so I stopped to run into get lunch and when I went to restart the truck the fuel pump would not run kinda.

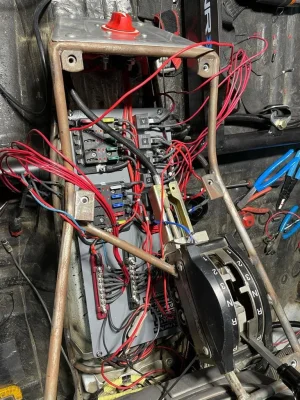

So iv wired my Bosch 044 to the stock 12v fuel pump wire that is powered off the ignition so it starts and run like a stock truck. So the problem is when I turn the key to ACC no fuel pump. As soon as I turn the key to run the starter the fuel pump starts the truck fires up and as soon as I let go of the key from the starter position it kills the fuel pump and truck dies.

I haven’t really dug into the situation to deep as it was about 95 degrees and I had my 2 month old with me so I simply hot wired the pump strait to the battery and drove home.

Then on Friday I buttoned the whole truck back up and brought it out of the garage for the first time in months and cleaned it up. Took it down to cars and coffee to meet a buddy Saturday morning down there. Even brought the kid.

Now this is the part I’m hoping to get some ideas from you guys. After driving the truck back home about 30 miles or so I stopped to run into get lunch and when I went to restart the truck the fuel pump would not run kinda.

So iv wired my Bosch 044 to the stock 12v fuel pump wire that is powered off the ignition so it starts and run like a stock truck. So the problem is when I turn the key to ACC no fuel pump. As soon as I turn the key to run the starter the fuel pump starts the truck fires up and as soon as I let go of the key from the starter position it kills the fuel pump and truck dies.

I haven’t really dug into the situation to deep as it was about 95 degrees and I had my 2 month old with me so I simply hot wired the pump strait to the battery and drove home.