You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody have tips for regearing?

- Thread starter 95_Bluwhale

- Start date

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

Correct, takes more than 1-3 adjustments to get correct on average. Dont be alarmed, you want it just right and patterns looking similar to the finished picture above from SByota. Also if you run out of gear mesh goo, you can use white or silver anti sieze. It works as well. I’d suggest white so you can see it but depends on your age lol. I build gear assemblies at day job gears cost 50k and I used anti sieze. Ca does not sell gear marking compound for fear of cancer chems. FYI.Take your time and don’t be afraid to do it over and over again. I think people’s biggest mistake is getting frustrated after trying 23 different shims combos and just saying “close enough” and putting it together.

Start with whatever shims the diff had in it and work form there. Usually you have to overshoot the pinion depth a little to then work back to the “perfect” pattern.

The most simple explanation is, the pinion depth sets the pattern. The carrier shims set the backlash and carrier preload. You and SLIGHTLY tweak the pattern with the backlash, but that’s an advanced skill.

Carl Jantz had a good explanation of pattern changes vs shim changes.

https://youtu.be/nVb5WRUfM7Y?si=psFULeqeozFBvDAP

I am your basic garage mechanic and have set up several of my own diffs and nothing has exploded yet. Front “clamshell” Toyota diffs are terrible! Be grateful you are not doing one.

View attachment 46159View attachment 46160View attachment 46161

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

9”

Is way easier than all of the above. Might want to grab a junk yard on and we do VSS configuration instead. Not to get you side tracked but an easier option to work on as needed. I figured out all the VSS shit back in the day. I can look at my notes if needed.

Is way easier than all of the above. Might want to grab a junk yard on and we do VSS configuration instead. Not to get you side tracked but an easier option to work on as needed. I figured out all the VSS shit back in the day. I can look at my notes if needed.

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

Picking up a carrier tomorrow from marketplace so i can start with the front first

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

Future plan that's why doing the 8.8 the cheap way with a lunchbox locker but the truck desperately needs the gears9”

Is way easier than all of the above. Might want to grab a junk yard on and we do VSS configuration instead. Not to get you side tracked but an easier option to work on as needed. I figured out all the VSS shit back in the day. I can look at my notes if needed.

Tree trunk

Well-known member

Sorry stupid autospell. I and 4.10* can anyone teach me how to edit after posting please? Jeez.

At the bottom left of your post, next to the report button are three dots. Click that and it gives you the option to edit

Use your old bearings as set up bearings. After you press them off your old stuff, Dremel them out some so it's not exactly a press fit anymore. This way there's no chance of hurting new bearings with the press if they have to go on and off again. Last time I set it up slightly loose so the new bearings took up the slack, but it's been a few years so I can't say particular measurements.

Also, start with the measurements in place (using the old shims as a guide) it usually lands you pretty close.

I have done this and both times the shims I used on old bearing were not correct so wasn't worth the time or anything to do it. I just install stock shims back on the new bearings and gears and run pattern. With bearing puller you can remove and change them if needed.

Front D44 I just did was installed all stock shims with new bearings on new carrier and everything was perfect ready to go.

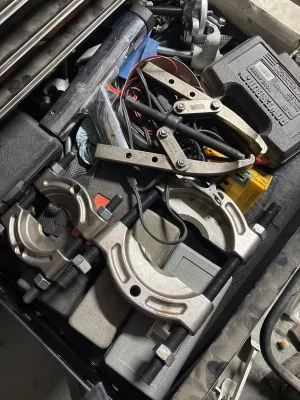

I have one of these and I used it to remove stock D44 carrier bearings and pressed onto new 4.56 carrier and it worked perfect.

https://www.amazon.com/VEVOR-Carrier-Pinion-Bearing-Puller/dp/B09RHXDMBP

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

Kind of my plan just to see how stock shims fit post the pattern and see the overall consensusI have done this and both times the shims I used on old bearing were not correct so wasn't worth the time or anything to do it. I just install stock shims back on the new bearings and gears and run pattern. With bearing puller you can remove and change them if needed.

Front D44 I just did was installed all stock shims with new bearings on new carrier and everything was perfect ready to go.

I have one of these and I used it to remove stock D44 carrier bearings and pressed onto new 4.56 carrier and it worked perfect.

https://www.amazon.com/VEVOR-Carrier-Pinion-Bearing-Puller/dp/B09RHXDMBP

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

Thank you so much man! Noob don’t mind me.At the bottom left of your post, next to the report button are three dots. Click that and it gives you the option to edit

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

FYI VSS tooth count is gear specific, the rest of the dudes apparently don’t know this. Anyway it makes exsisting ford math work so your speedo is accurate and shift points are correct. Hit me up when you’re ready. You only get like 5 resets of the VSS value before ECC-IV needs to be re-flashed or guage cluster replaced. So getting the correct value the first time is important, regardless of what rear axle type is.Future plan that's why doing the 8.8 the cheap way with a lunchbox locker but the truck desperately needs the gears

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

Yeah that was something I was hoping for I’ve read about it but not the processFYI VSS tooth count is gear specific, the rest of the dudes apparently don’t know this. Anyway it makes exsisting ford math work so your speedo is accurate and shift points are correct. Hit me up when you’re ready. You only get like 5 resets of the VSS value before ECC-IV needs to be re-flashed or guage cluster replaced. So getting the correct value the first time is important, regardless of what rear axle type is.

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

You’ll need a mag base a plunge indicator to check backlash. You can get a cheap one on Amazon it should due. I advise .0005 accuracy but .001 will get the job done. Usually there’s a higher price for 5 tenths vs 1 thou. But how often are you going to use it decides what you will buy.

If you want the good shit, Noga mag base and mitutoyo, .0005 plunge indicator. But peacock, aerospace, fouler brands ect will do just fine.

If you want the good shit, Noga mag base and mitutoyo, .0005 plunge indicator. But peacock, aerospace, fouler brands ect will do just fine.

Attachments

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

I have one from the time I swapped gears into the current housing but that was very minimal work compared to the whole swapping gears cause now I actually have to set it up from the starts I also found on it my master overhaul kit is missing bearings so new kit comes WednesdayYou’ll need a mag base a plunge indicator to check backlash. You can get a cheap one on Amazon it should due. I advise .0005 accuracy but .001 will get the job done. Usually there’s a higher price for 5 tenths vs 1 thou. But how often are you going to use it decides what you will buy.

If you want the good shit, Noga mag base and mitutoyo, .0005 plunge indicator. But peacock, aerospace, fouler brands ect will do just fine.

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

Alright I tried and I threw in the towel anyone know a shop or someone that can handle the job I have all parts so just the labor I have both axle and diff out so it’s easier already got quoted 1200 but not until mid Jan

95_Bluwhale

Active member

- Joined

- Jul 24, 2022

- Messages

- 303

The not having an easy way to take the pinion bearing off and put it on already messed one up new one comes tomorrow and I’m in Pomona,Ca

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

RMC

Active member

- Joined

- Oct 27, 2025

- Messages

- 131

Im only line an hour away, when you way pinion bearing do you mean the half on the pinion shaft or the half on the housing? Slid hammer with hook tip for housing side, half moon puller and slide hammer or press for the bearing side.

Attachments

Similar threads

- Replies

- 36

- Views

- 3K

- Replies

- 10

- Views

- 2K

- Replies

- 41

- Views

- 5K

- Replies

- 3

- Views

- 1K

- Replies

- 75

- Views

- 8K