MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

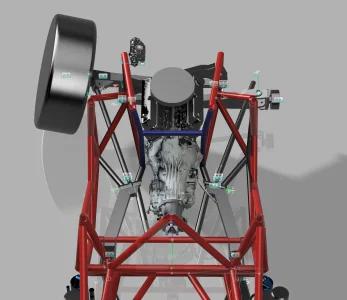

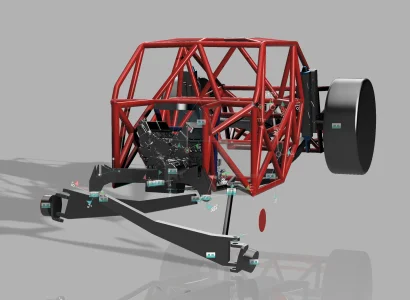

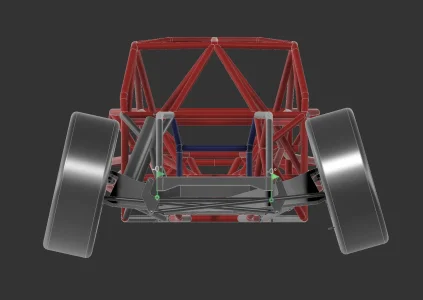

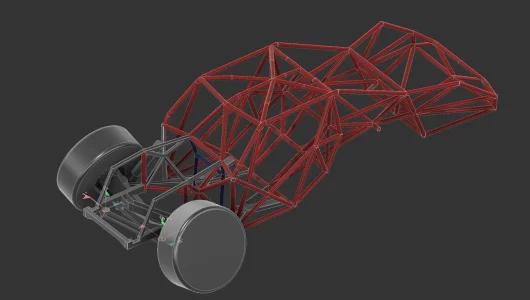

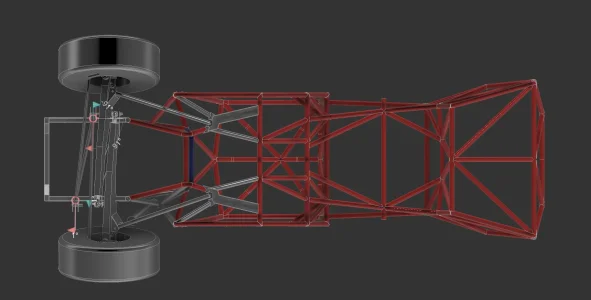

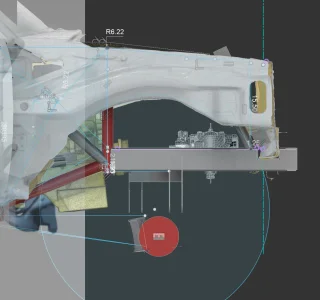

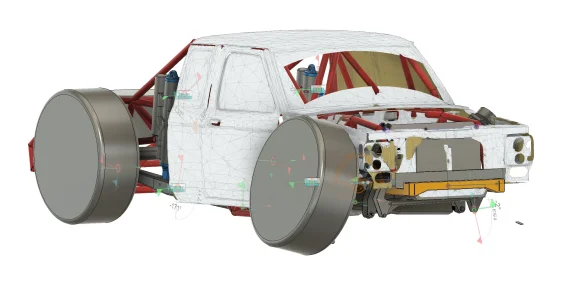

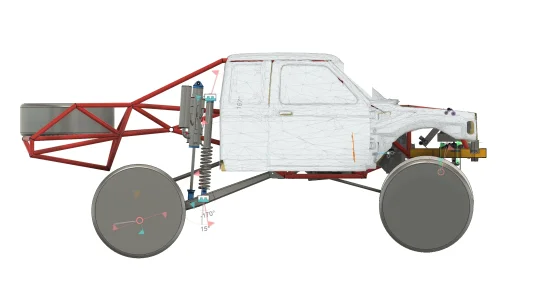

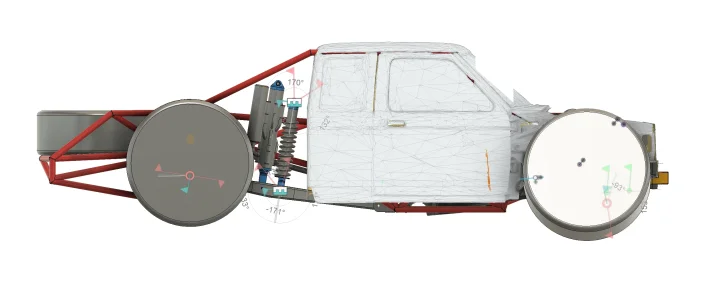

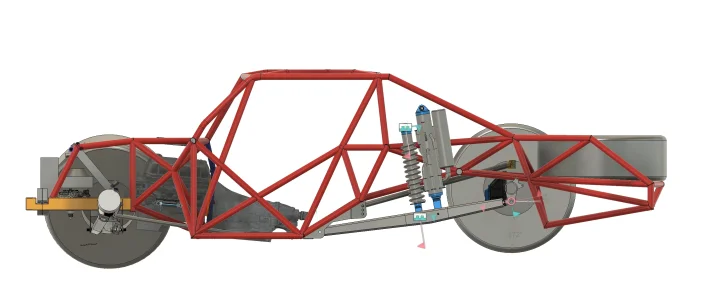

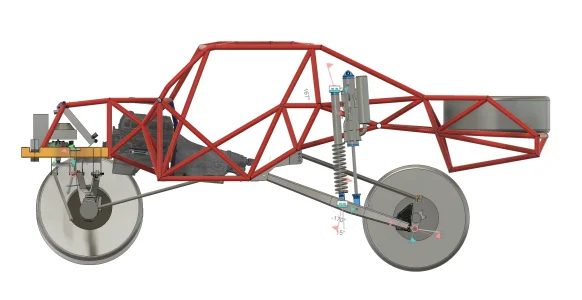

With the drivetrain placed damn near close, I spent the rest of the day locating my radius arm mounts. Kept them as long and near center as I could while keeping the middle open for ease in removing the transmission for service. Planning on finalizing/cleaning up the plate work on it in a few days. Other than adding a few more tubes to the engine bay, will do one more look over on tube interferences and send the chassis off to laser.

Been chipping at this project for the last 5 years, definitely itching to put this puzzle together. Given I already have most of the suspension/drivetrain ready, would like to see this thing rolling relatively shortly after starting. Appreciate all the help from everyone along the way.

Been chipping at this project for the last 5 years, definitely itching to put this puzzle together. Given I already have most of the suspension/drivetrain ready, would like to see this thing rolling relatively shortly after starting. Appreciate all the help from everyone along the way.