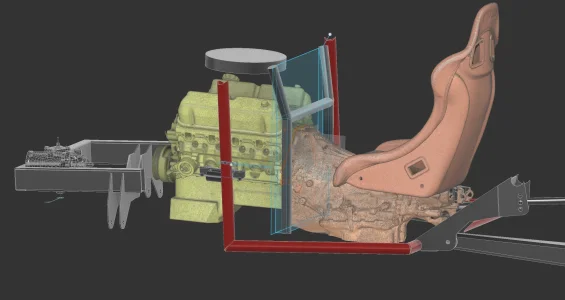

3/8" is pretty thin. The only mod you'll need to do is spacing with the torque converter, starter spacing, longer dowel pins, etc. Looks like a Ford engine with a C6?

Personally I would soft mount the engine and transmission. Makes for a way quieter and smoother deal. I would also recommend an overdrive transmission; you'll be bummed with a C6 (hard to get parts; and only 3 forward gears). i would do a Reid Case 4L80 with a Ford bellhousing if you want to keep the Ford engine. It'll bolt right up