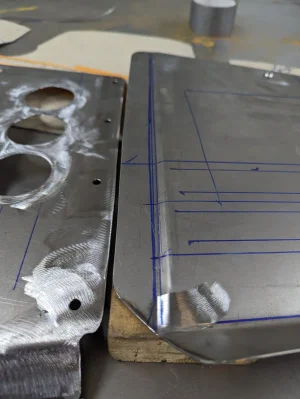

looks so fucking good Tommy.

also, to you and anyone else who does this, fucking props for posting sooooooooooo many pictures of not every step but, A LOT of the steps youre taking to get to what youre making. it might just be me but, "oh just take a few pics while your working so i can see!".......... is really NOT that fucking simple. maybe physically, yeah it doesnt take much work but, to stop what youre fucking doing, pull/go get your phone out, plan the right angle/zoom of the picture, take the picture and make sure its somewhat focused, then put everything back to where it was and get back into the groove of whatever the fuck you were doing.............. idk. its a lot, and like i said could just be me and being to worried about banging mawmacitas at the same time, or very likely because im legitimately fucking retarded. but SAME SAME.

im just saying thank you!!!!!!!!!!!!!!!!!!