You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sequoia Family Crawler

- Thread starter Motiracer38

- Start date

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Transmission is the stock A340 2wd Sequoia edition with 5 pinion rear planetary. I modified a 98-01 XJ AW4 output shaft and used the AW4 4wd adapter to mount up the NP231. A pickup VSS fit in the housing and should read the XJ 4 pulse ring but hasn't been tested yet.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Only reason for the odd ball setup was to reduce the price of installing a doubler. Definitely not easier or quicker.

You could wire up the ebrakes for cutting but the couple reviews I've read from others that have them working is they are easily driven through so probably not too effective. Also would need a selectable rear locker and the Ford e-locker jumped in price from $500 to $900 so I may end up up with a $400 racheting one to save cost

You could wire up the ebrakes for cutting but the couple reviews I've read from others that have them working is they are easily driven through so probably not too effective. Also would need a selectable rear locker and the Ford e-locker jumped in price from $500 to $900 so I may end up up with a $400 racheting one to save cost

smokeysevin

Active member

- Joined

- Mar 7, 2023

- Messages

- 240

Transmission is the stock A340 2wd Sequoia edition with 5 pinion rear planetary. I modified a 98-01 XJ AW4 output shaft and used the AW4 4wd adapter to mount up the NP231. A pickup VSS fit in the housing and should read the XJ 4 pulse ring but hasn't been tested yet.

You got any shaft pics?

Of the modification I mean.

Sean

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Still working away on this thing, been able to get a couple solid weekends in and getting close to the end. Somehow the to-do list gets longer as I cross things off though so that's aggravating.

Got the front bumper done for now, will get a skid plate later.

Got the steering box ports for the assist welded up and built the pitman arm brace.

Got the front bumper done for now, will get a skid plate later.

Got the steering box ports for the assist welded up and built the pitman arm brace.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

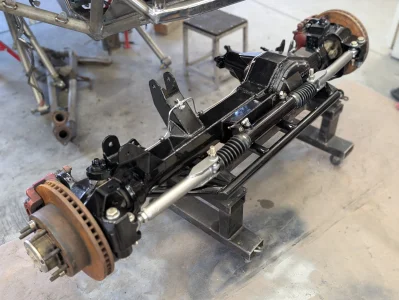

I like the hard brake line on the front axle. Makes it way easier and better than long lines that might get caught on something as it all moves and flexes out.

Also double ended ram as a tie rod is cool too since it has equal steering each way.

Also double ended ram as a tie rod is cool too since it has equal steering each way.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Equal force is why I went that way. Admittedly I have never driven with a single ended ram but it didn't seem like something I wanted.

GahnRacing

Well-known member

- Joined

- Apr 4, 2022

- Messages

- 418

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 975

Rude!

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Well I made a valiant effort to take advantage of the 4 day weekend with no plans other than to finish this thing up. Came up a but short but not due to a lack of effort.

Got all the paint on the front end and assembled the entire engine bay, front links, and the entire exhaust. Mounting the battery, fuse boxes, hoses, reservoirs and every else took forever but all came out pretty clean. The wiring harness is even designed and re-wrapped to the correct length. Still need to mount the winch solenoid box somewhere.

Found out Seymour stainless doesn't really like spraying in a 95deg garage.

Got the brake relocation setup in and working well. The dual arms were needed for the forward offset of the master to avoid side loading.

Even got the shifter installed and poking through into the interior.

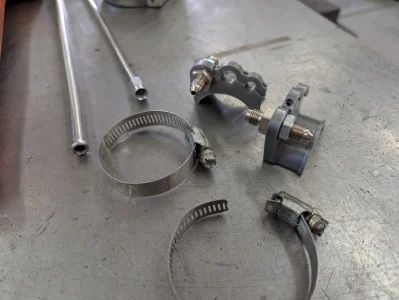

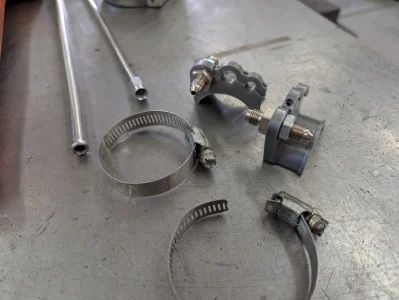

Got a start on the link mounted lines but came up short on AN nuts. These are 3D printed from PETG to see if they'll hold up.

Got all the paint on the front end and assembled the entire engine bay, front links, and the entire exhaust. Mounting the battery, fuse boxes, hoses, reservoirs and every else took forever but all came out pretty clean. The wiring harness is even designed and re-wrapped to the correct length. Still need to mount the winch solenoid box somewhere.

Found out Seymour stainless doesn't really like spraying in a 95deg garage.

Got the brake relocation setup in and working well. The dual arms were needed for the forward offset of the master to avoid side loading.

Even got the shifter installed and poking through into the interior.

Got a start on the link mounted lines but came up short on AN nuts. These are 3D printed from PETG to see if they'll hold up.

SByota

Well-known member

That’s some pretty awesome progress!

Did you 3D print that MAF/air filter mount adapter? If so, want to print another one, I could definitely use it with my V8 Tacoma swap.

Did you 3D print that MAF/air filter mount adapter? If so, want to print another one, I could definitely use it with my V8 Tacoma swap.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

I did design the relocation assembly on CAD, hand cut everything and built it. Needed to clear the shock and convert to a 2500hd master to match the caliper bore sizes.

Designed and printed the MAF mount as well. A 30 hour print that took 4 days due to filament issues but it ended up bolting right up. I'm a little nervous on reliability but it should hold up to under hood temperatures.

Designed and printed the MAF mount as well. A 30 hour print that took 4 days due to filament issues but it ended up bolting right up. I'm a little nervous on reliability but it should hold up to under hood temperatures.

WW_RANGER_X

Well-known member

Looks great, dude!

the bodj

Well-known member

Designed and printed the MAF mount as well. A 30 hour print that took 4 days due to filament issues but it ended up bolting right up. I'm a little nervous on reliability but it should hold up to under hood temperatures.

What type of plastic did you use?

The joys of 3D printing. I just did an 11 hour print for a cradle for my m18 impact, only for it to finish and be entirely too large. I goofed on the scale somewhere along the way

Similar threads

- Replies

- 10

- Views

- 246