Long time no update but work has been slow and steady. Fuel and brake lines are all remade from stainless hard line and -3AN braided hose. Stock fuel pump and EVAP system all remain in place.

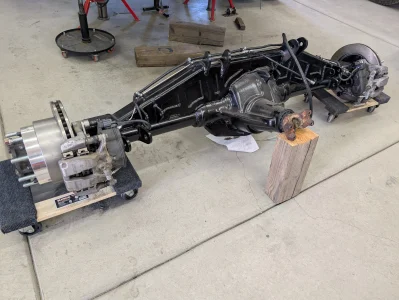

Rear axle is complete, trussed and 2019 F150 Electric E-brake calipers all mounted up.

View attachment 40363

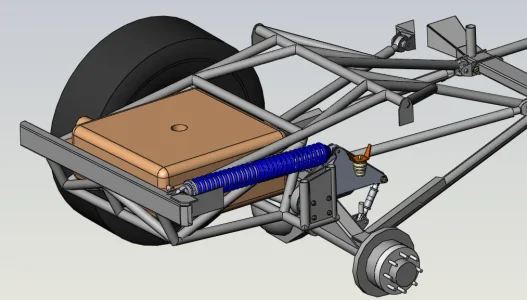

Rear cantilever final assembly complete. Calculated spring rate is in place but have yet to check ride height. 23in of travel with 8in bump should work in the desert well. Trying closed cell foam bumpstops to reduce noise, hope they are stiff enough.

View attachment 40364

Built the start on some rock sliders to ward off typical rock rash. Only a bit of clearancing needed in the rear wheel wells.

View attachment 40365

View attachment 40366

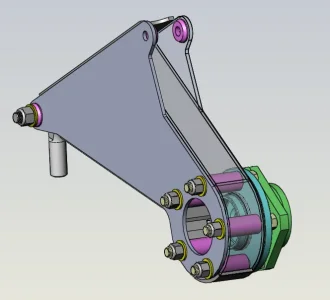

And finally got the transfer case built up. NP231 doubler in front of a NP242 with a 6 gear input planetary and 32 spline slip yoke eliminator. Drvieshafts are on hand but yet to be fit.

View attachment 40367