Tree trunk

Well-known member

Thanks dude, I know ice cream fucks me up up but I took a gamble on some scetchy looking mint and chip anyways.That sounds like a wonderful Saturday night. Feel better

That’s how she goes

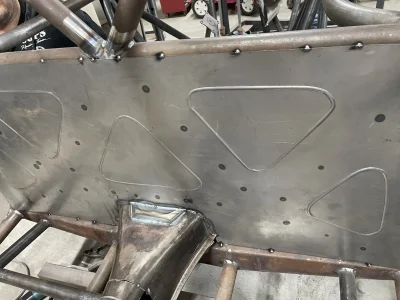

I went to cal-mesa steel the other day for some tube and just for fun I got a quote for a sheet of 3/16 chromoly…. Granted cal-mesa isn’t the cheapest metal supply. I wanna say that sheet he quoted me for was approaching 600 bucks….. yikes