Forget Regrets

Member

Copied from my original thread on DR, will just copy, paste, and post as time allows. So starting from 2019 is as follows…

Waited until I was getting the new kit on this truck to make a build thread.

I bought the truck over a year ago off of Christian Ewing. It has the 4.2 V6, cold air intake and throttle body spacer. 8.8 rear end, re-geared to 4:56. 37” typo open country R/T on walker Evans beadlocks; wheel pattern 5x135mm. Simple cab cage (needs some work) bed cage, deavers, and king 2.5x14” 2 tube piggy back. The front was a CST long travel kit with Fox 2.5x8” COHR. Had all heims and uniballs or upgraded bushings. Worked good but really needed an air bump.

I changed out the 2 tube piggy back bypasses for 3 tube hose remotes, put a longer driveshaft on it, put the light box from my ranger on the back of the F150, added an external trans cooler with fan, and added a LED light bar to the front bumper.

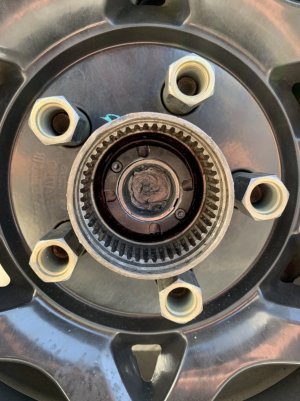

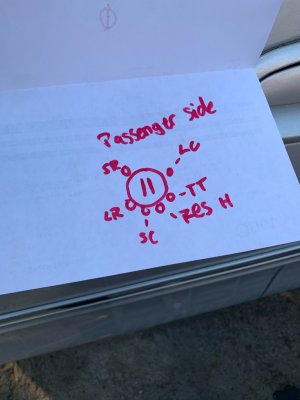

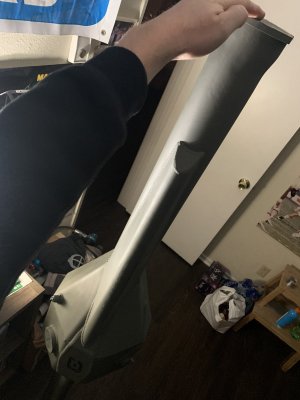

Last fall I bought Jerry Larimore’s old HM race kit. The kit that ODR fab fixed and made better. Over the last 6 months or so I had been collecting parts for it. Got the kit powder coated (probably should’ve waited on that) new 1.5” uniballs and heims for the steering through some friends, wilwood 4 piston calipers, king 2x2 bumpstops and cans, Dana 44 hubs, and snouts. Upgraded to 5/8 studs and had eversen performance redrill the rotors and hubs to my wheel pattern. I had bought front and rear shocks for my ranger before I blew the motor and transmission. I have 2.5x10 dual rate coil over hose remote with adjusters and 2.5x14” coil over hose remote with adjusters for the rear (when I get there). Gonna use the the 55” BTF links I bought for the ranger too.

Last week brought the truck in for the install and this is where we are at the moment. Had to drill out the lower pivot points to 3/4”, make some weld washers, plate the frame, and mock up where the upper arms are going to land. We had to cut off all the stock upper arm mounts, previous shock mount tabs, and eventually dismantle the stock brake calipers.

Pictures before and where I’m at. Will post updates as we go.

Waited until I was getting the new kit on this truck to make a build thread.

I bought the truck over a year ago off of Christian Ewing. It has the 4.2 V6, cold air intake and throttle body spacer. 8.8 rear end, re-geared to 4:56. 37” typo open country R/T on walker Evans beadlocks; wheel pattern 5x135mm. Simple cab cage (needs some work) bed cage, deavers, and king 2.5x14” 2 tube piggy back. The front was a CST long travel kit with Fox 2.5x8” COHR. Had all heims and uniballs or upgraded bushings. Worked good but really needed an air bump.

I changed out the 2 tube piggy back bypasses for 3 tube hose remotes, put a longer driveshaft on it, put the light box from my ranger on the back of the F150, added an external trans cooler with fan, and added a LED light bar to the front bumper.

Last fall I bought Jerry Larimore’s old HM race kit. The kit that ODR fab fixed and made better. Over the last 6 months or so I had been collecting parts for it. Got the kit powder coated (probably should’ve waited on that) new 1.5” uniballs and heims for the steering through some friends, wilwood 4 piston calipers, king 2x2 bumpstops and cans, Dana 44 hubs, and snouts. Upgraded to 5/8 studs and had eversen performance redrill the rotors and hubs to my wheel pattern. I had bought front and rear shocks for my ranger before I blew the motor and transmission. I have 2.5x10 dual rate coil over hose remote with adjusters and 2.5x14” coil over hose remote with adjusters for the rear (when I get there). Gonna use the the 55” BTF links I bought for the ranger too.

Last week brought the truck in for the install and this is where we are at the moment. Had to drill out the lower pivot points to 3/4”, make some weld washers, plate the frame, and mock up where the upper arms are going to land. We had to cut off all the stock upper arm mounts, previous shock mount tabs, and eventually dismantle the stock brake calipers.

Pictures before and where I’m at. Will post updates as we go.