You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

92 Ranger rebuild

- Thread starter 85Yota

- Start date

Well started mocking up the shocks today and the tube I don't like interferes with the Coilover. Do I made executive decision to remove the cell and move it behind the axle. The rear area doesn't need a full box just a few spots for some action packer type boxes with spare parts fluid container and jack. So that will all fit between the cell and the laid down spares on a lid. Redid the front tubes on each side like I originally wanted them to be like. The down tubes from top of cab will land at the junction of these tubes. From the upper rear side of bump tube it will angle down to the bottom of fuel cell cradle, sway bar tube etc. no dead tubes and keep it all flowing good like it should.

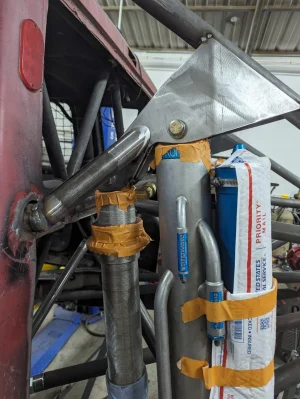

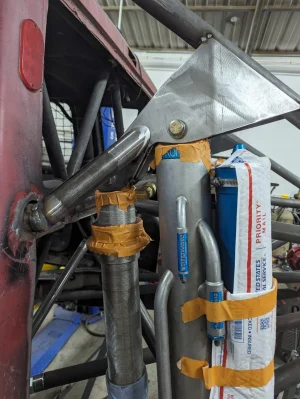

Got the miter outer tube done and tacked in, these were not fun with the miter being at a strange angle and the shock mounts needed a long angle. Got the inner shock mounts and a boxing piece between them tacked in place. Of course after I tacked them in and welded the top to the tube I noticed the bypass is probably going to contact them at full droop so gonna check that tomorrow and modify as necessary.

the bodj

Well-known member

Morgan Clarke designs just did same style on a t100 he's building. I also did same thing in a ranger I built back in 2008 and it's still running same cage work with a built ls3 and 40s now. I'm not worried about it moving at all on this play truck. If racing I'd not worry about back window and tie it all in to harness bar and C pillar. Sacrifice's are made to keep some amenities for the customer.

the bodj

Well-known member

Yeah, but Morgan's designs are pretty gross looking.

Damn, making me go back and look at some things up close. Most everything I’ve seen from him looks absolutely killer.Yeah, but Morgan's designs are pretty gross looking.

the bodj

Well-known member

Damn, making me go back and look at some things up close. Most everything I’ve seen from him looks absolutely killer.

The fab work is beautiful, though I've heard some panels don't fit together as well as you'd expect. I was talking more about his designs. The organic/freeform stuff is really ugly. I'd be pissed if I spent that kind of money for my trophy truck to look like the goblin lookin' thing he's building

For sure. I could see how there are varying opinions when it comes to visual aesthetics. He presents it as artwork a lot of the time, which I agree, it is a work of art. I’m sure he works with his customers and presents idea prior to physical work, but yea, I couldn’t even imagine what kind of cash dudes are shelling out for one of his builds. Probably cheaper to just buy a Gieser TT Lol.The fab work is beautiful, though I've heard some panels don't fit together as well as you'd expect. I was talking more about his designs. The organic/freeform stuff is really ugly. I'd be pissed if I spent that kind of money for my trophy truck to look like the goblin lookin' thing he's building

The fab work is beautiful, though I've heard some panels don't fit together as well as you'd expect. I was talking more about his designs. The organic/freeform stuff is really ugly. I'd be pissed if I spent that kind of money for my trophy truck to look like the goblin lookin' thing he's building

Yeah I'm not a fan of the Eversen 6100 that he turned into a SUV look with his paneling.

I'm gonna add a tube from the junction up to the top by the cab where window will still be able to install etc. The shock mount doesn't look complete now that I got it on and been looking at it. was gonna run another tube on opposite side to the tube that goes into cab below window BUT it would have to land in a dead spot to be able to get the bolt in and out without interference.

Well got the rear fuel cell cradle tray tubes in place. Now I can put some plates to keep it from sliding around and then do the hold downs structure. Will have trans cooler mounted top on tube above axle and rear bottom of cooler near fuel cell. The front of the fuel cell cradle is 1-1/4" tubing and only has the one support in middle to it. My friend said that a bigger fuel cell may be in this trucks future so that portion will be easier to remove if that happens. If not it will be plenty strong in its current situation.

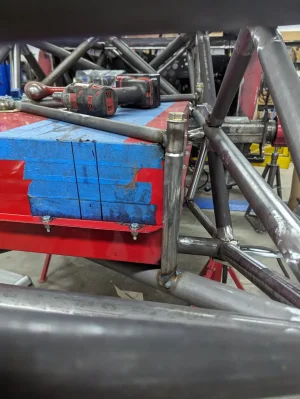

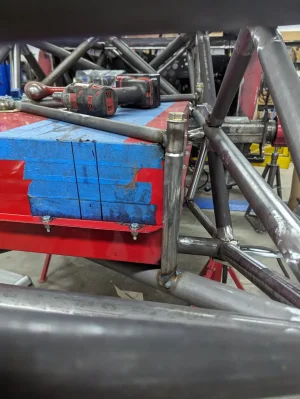

Ok got big trans cooler in place. Drilled tapped cross tube for upper mount and put another 1-1/2 tube between rails Infront of the cell that I landed a lower tab off on. Then added a couple diagonals from lower frame bump area to center to keep everything square and tight. Also fuel cell cradle is in and welded up too.

Pictafiedesign

Well-known member

- Joined

- Jul 11, 2023

- Messages

- 274

Just got doin this on mine as well! lol. Some good progress dude!Ok got big trans cooler in place. Drilled tapped cross tube for upper mount and put another 1-1/2 tube between rails Infront of the cell that I landed a lower tab off on. Then added a couple diagonals from lower frame bump area to center to keep everything square and tight. Also fuel cell cradle is in and welded up too.

View attachment 18687View attachment 18688View attachment 18689View attachment 18690View attachment 18691View attachment 18692View attachment 18693View attachment 18694

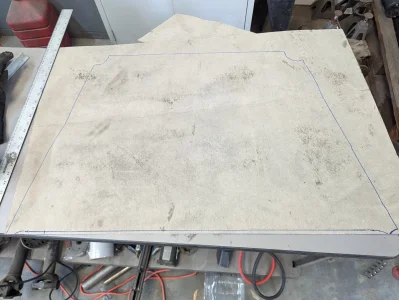

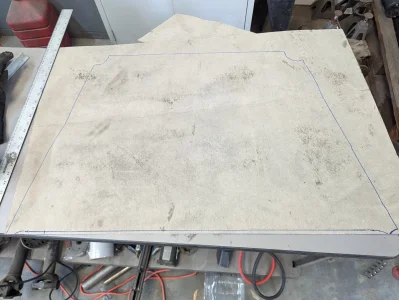

Starting on the floor and rear firewall. Going to make the middle rear panel tight against the X below back window. Then angled triangle pieces from the cab to that tube as well. Then a bottom triangle to box it all in.

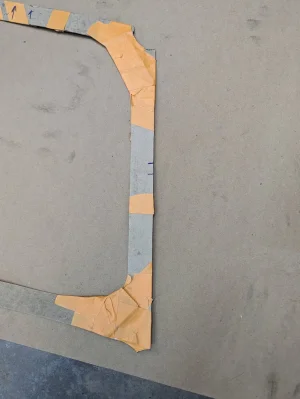

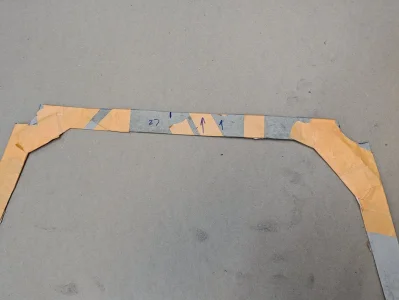

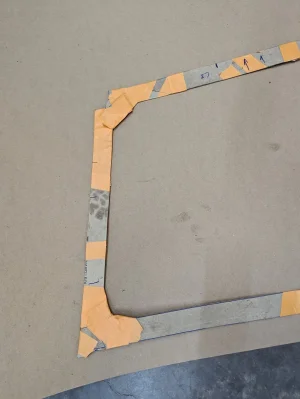

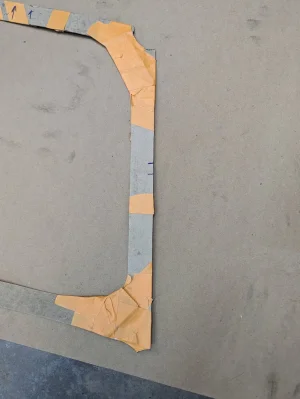

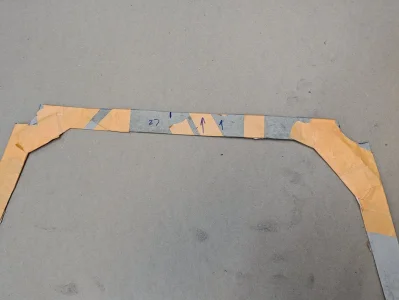

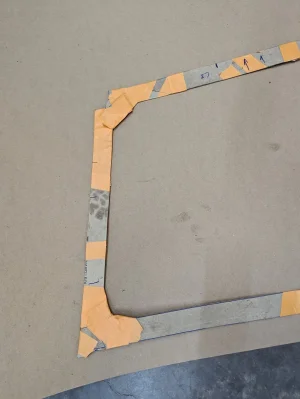

When making these big panels it's hard to fit a big sheet of ram board in for the templates. So I measure lengths of each side and cut some 1-1/2" strips then trim ends and mark and fit each side. Then more tape and shorter ram board pieces on the corners to make a frame that gets transferred to a big panel that is fit in place and trimmed as needed then traced into sheet metal. Using 18 ga sheet and big panel will have some bead rolls to make it not rattling.

When making these big panels it's hard to fit a big sheet of ram board in for the templates. So I measure lengths of each side and cut some 1-1/2" strips then trim ends and mark and fit each side. Then more tape and shorter ram board pieces on the corners to make a frame that gets transferred to a big panel that is fit in place and trimmed as needed then traced into sheet metal. Using 18 ga sheet and big panel will have some bead rolls to make it not rattling.

OK back to work on this for a few days now and I haven't updated this thread in a while. Back firewall pieces are in except middle which I'll finish after I get the driveshaft and carrier bearing crossmember made. Rear air bumps are on and scrub 1/8" at full 4" stroke and line up perfectly on the backhalf tube's since I calculated the angle they would be st when designing that stuff. Also mounted the rear light box as well.

Similar threads

- Replies

- 17

- Views

- 613

- Replies

- 5

- Views

- 315

- Replies

- 43

- Views

- 4K

- Replies

- 13

- Views

- 887