MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Was able to do a bit more work on the truck with the info I've been given. With the 16/18 setup I'm getting around 30" of travel, and this is what the sway bar angles are looking like.

Should be fine, guys are running 34-36" with minimal plunge. From ride height it's 13 degrees up, 16 degrees down. Travel still has to be restricted with limit straps and bumpstops/rubber stops on the shocks.driveline gonna handle that much travel?

I was considering trading my 18” coils for 20”s to get the 4” more inches^^ I just looked back... your links are 60" long. Makes more sense now.

Either way... seems like too much travel!!!

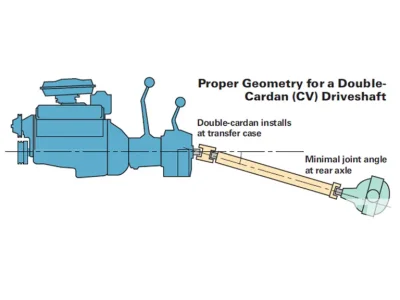

Correct depends on joint type. However from what I understand the 3° is for normal driving angles. You should not see the same forces on the driveline at full droop (in the air)Correct me if I'm wrong, but I believe a lot of this depends on driveshaft joint type.

View attachment 45751

For what it looks like you're doing (keeping trans output parallel with the pinion), there is a margin of about 1* in either direction that they can be out of alignment and not cause vibrations. You can mess with link and pivot geometry to induce a small amount of rock back on the pinion to help your angles at full droop.

I’m reading on trucks with 4”, but that’s with larger travel numbers. I’m sitting at 30” metal to metal so it will be bumped and strapped short2.6" of plunge is too much, 1" or less is a number to shoot for. 34-36" of travel is not gonna happen without bad side effects, 30-33" and you'll be way better off. Most fight vibration at some point in the travel, droop is a common one. Try lowering your tailshaft pivot and check your plunge again. 13" of up travel is a fair amount, drooping 15"+ is going to cause binding. What are you horizontal/vertical pivot measurements at the frame?

Here's the 4 link calculator I used. I know you're solid at CAD, but this spits out the numbers really fast

https://irate4x4.com/resources/4-link-calculator.4/updates#resource-update-133

Download button is in top right

This has been the calculator I’ve been working with. Big help but doesn’t answer all these more technical questions.What motor is this thing going to get? 30" is a lot to push through

The 6.35” vert is correct. Not sure about the 10” horizontal, that doesn’t make sense. The upper and lowers have about 38” horizontal at the frame. There’s ~11” vert at the axle end. If I start to raise the separation at the frame to “help” the pinion angle stay the same (parallel upper and lowers), the anti squat quickly drops into the 20-30%.Don't go off what people say, go off what works for you. Keep the u joint angles at the trans happy and the plunge numbers as low as possible. If I read that correctly you have 6.35" vertical and 10" horizontal separation at the frame end? Whats your u joint centerline height at the trans from the lower link pivot at the frame? Guessing your shooting for a belly height of 19-20" from ground or do you have the lower link mounts beneath the belly?

The 6.35” vert is correct. Not sure about the 10” horizontal, that doesn’t make sense. The upper and lowers have about 38” horizontal at the frame. There’s ~11” vert at the axle end. If I start to raise the separation at the frame to “help” the pinion angle stay the same (parallel upper and lowers), the anti squat quickly drops into the 20-30%.

Lowers are raised 2” from the belly of the cab to help with the anti squat numbers at the ride height I want. They are 21” from the ground