Hey all!

This is my old ford project!

It's a 1982 F250, engine is a ford 400, it has a T18 4 speed aka 3 speed. Dana 60 rear and 44HD TTB front.

I really enjoy driving this thing! I wanted to rebuild it into something to chill with and cycle into a daily driver, it's nothing hard core just a build I am doing for fun.

Starting in the back.

Because of an abundance of raptor parts around my house I decided to do a rear raptor suspension conversion, I mean it's really just shocks and leafs so pretty much the exact thing it came with from 82.

First thing was getting the leaf springs set up

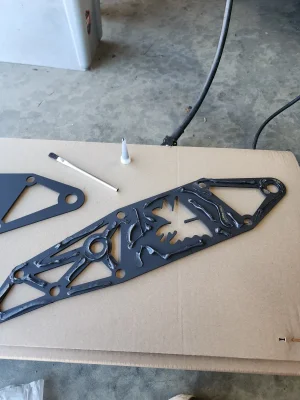

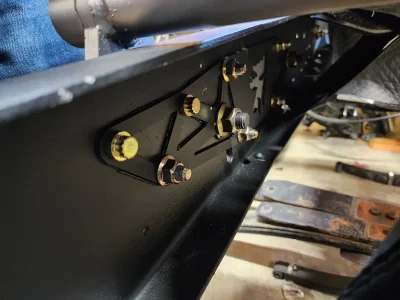

I got some fabricated leaf mounts from desolate. The rear I keept in the stock location lwtting the shackle do the location work. The front I had to move forward a bit to compensate for the extra leaf length.

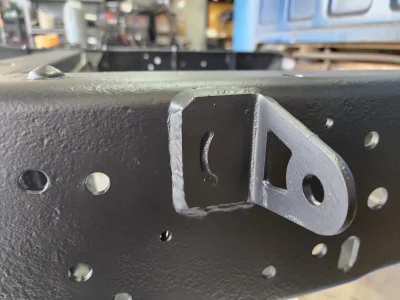

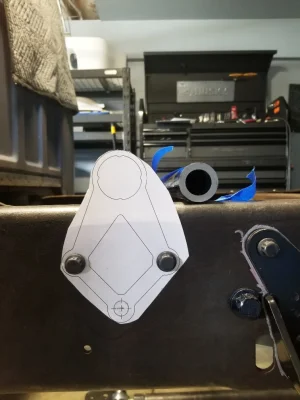

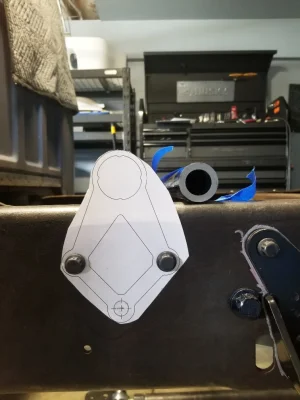

I made a doubler plate that will also serve to locate the fron spring mount. It locates off the OEM frame 3/4" frame alignment holes.

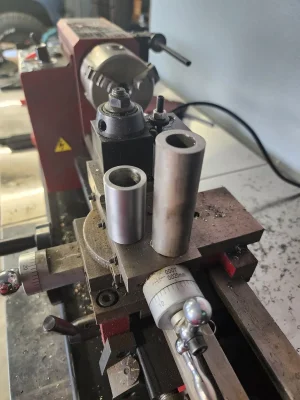

Then on the axle, I needed to convert it to a 2 pin leaf mount, I figured for sure the the pinion angles would be spot on form the two tucks so I based the sprin mount off the stock forged mounts on the axle even though they were in bad shape.

Well that was dumb and didn't work. The pinion angle was not ideal plus I just thought it was sketch.

So I Haddadddd to grind off the dang spring pearch. I got a new 3" wide pearch from barns 4x4 and tossed on a 2 pin top, set the pinion angle and was gtg. (This was wayyy later after pretending the original set up was good to go).

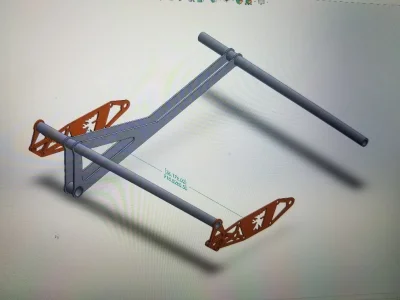

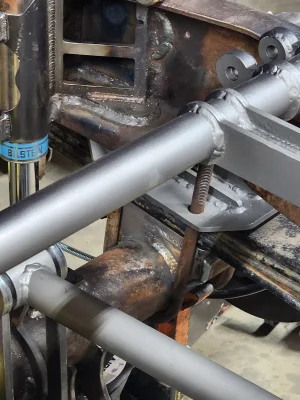

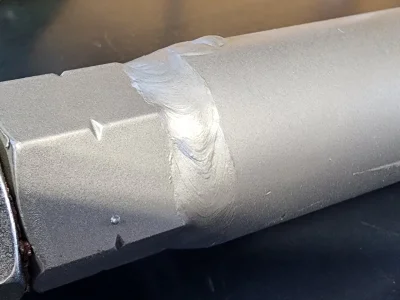

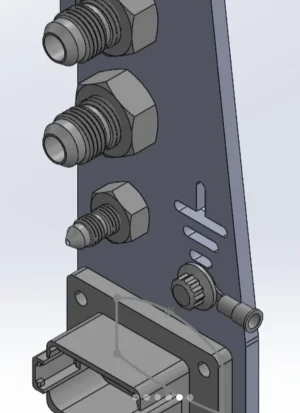

Mean while, I made a upper and lower shock mount. Now that I am confident in the spring cycle I locked in the upper location.

More updates to follow!

This is my old ford project!

It's a 1982 F250, engine is a ford 400, it has a T18 4 speed aka 3 speed. Dana 60 rear and 44HD TTB front.

I really enjoy driving this thing! I wanted to rebuild it into something to chill with and cycle into a daily driver, it's nothing hard core just a build I am doing for fun.

Starting in the back.

Because of an abundance of raptor parts around my house I decided to do a rear raptor suspension conversion, I mean it's really just shocks and leafs so pretty much the exact thing it came with from 82.

First thing was getting the leaf springs set up

I got some fabricated leaf mounts from desolate. The rear I keept in the stock location lwtting the shackle do the location work. The front I had to move forward a bit to compensate for the extra leaf length.

I made a doubler plate that will also serve to locate the fron spring mount. It locates off the OEM frame 3/4" frame alignment holes.

Then on the axle, I needed to convert it to a 2 pin leaf mount, I figured for sure the the pinion angles would be spot on form the two tucks so I based the sprin mount off the stock forged mounts on the axle even though they were in bad shape.

Well that was dumb and didn't work. The pinion angle was not ideal plus I just thought it was sketch.

So I Haddadddd to grind off the dang spring pearch. I got a new 3" wide pearch from barns 4x4 and tossed on a 2 pin top, set the pinion angle and was gtg. (This was wayyy later after pretending the original set up was good to go).

Mean while, I made a upper and lower shock mount. Now that I am confident in the spring cycle I locked in the upper location.

More updates to follow!