You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

THE NUCLEAR UNICORN

- Thread starter Ajones880

- Start date

Ajones880

Well-known member

I had planned to add weld washers to the inside of the tabs. After a ton of time and measurements over the weekend... I got it to cycle the entire 14" without any binding! I'm going to weld the washers on the outside now.On our beam setup we added weld washers to the inside to add room for articulation so the shock ends doesn't bind. Not sure if you're having similar issues

Ajones880

Well-known member

HAHAHA!! Yep! 3.0" 14" Coilover.then a coil over next to that big old sucker?

Ajones880

Well-known member

Thank you! all hand cut on the bandsaw and then finished on the DA sander and 12" bench sander.Very nice work. Nice edges on the plate work they look laser cut.

Ajones880

Well-known member

The limiting factor on my setup is the beams hitting the frame rail. My u-joints are heavily clearanced to accept maximum bump travel. This time around I may run RCV axles. Not too sure though. The bronco gets roughly around 18" of usable front wheel travel.What is the limiting factor for your up travel is it the driver side beam hitting the bottom lip of the frame rail? Or U joint bind?

Ajones880

Well-known member

I have not experienced any problems as of yet. I strap the front right around 18" of travel.I plan on grinding out the u-joints as well any issues in the passed with the u-joints after material is removed from them?

Ajones880

Well-known member

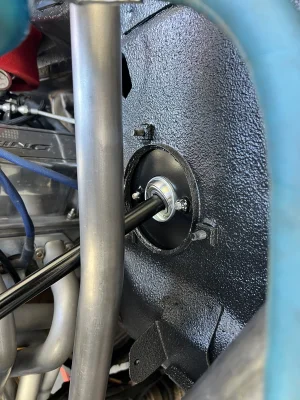

Slowly cranking along on the unicorn rebuild. Shock mount-tabs are almost completely finished up. Once that’s finished up, I’ll slowly tie up the dash and mount a few of the accessories. At the same time I’ll be in the process of designing/building a tube core support that will be tied into the engine cage structure, that will be 100% removable with grill, headlights, etc… #builtnotbought #onemanshow #garagefab #americanmade #builtintheusa  #kingshocks #moruzziracemotors #toyotires #threatmotorsports #familyfunhaver #prelander #badlinesgoodtimes #cleandezert

#kingshocks #moruzziracemotors #toyotires #threatmotorsports #familyfunhaver #prelander #badlinesgoodtimes #cleandezert

Attachments

Ajones880

Well-known member

Some Nuclear Unicorn updates.

Attachments

-

IMG_3434.webp989.8 KB · Views: 63

IMG_3434.webp989.8 KB · Views: 63 -

IMG_3521.webp1.4 MB · Views: 63

IMG_3521.webp1.4 MB · Views: 63 -

IMG_3522.webp1.6 MB · Views: 64

IMG_3522.webp1.6 MB · Views: 64 -

IMG_3523.webp1.4 MB · Views: 61

IMG_3523.webp1.4 MB · Views: 61 -

IMG_3524.webp1.4 MB · Views: 60

IMG_3524.webp1.4 MB · Views: 60 -

IMG_3432.webp960.7 KB · Views: 59

IMG_3432.webp960.7 KB · Views: 59 -

IMG_3431.webp907.3 KB · Views: 58

IMG_3431.webp907.3 KB · Views: 58 -

IMG_3334.webp1.4 MB · Views: 68

IMG_3334.webp1.4 MB · Views: 68 -

0D0A6811-72B8-40F5-B986-727934EC1478.webp478 KB · Views: 64

0D0A6811-72B8-40F5-B986-727934EC1478.webp478 KB · Views: 64 -

IMG_3398.webp1.1 MB · Views: 59

IMG_3398.webp1.1 MB · Views: 59 -

IMG_3401.webp1.2 MB · Views: 56

IMG_3401.webp1.2 MB · Views: 56 -

IMG_3400.webp1.8 MB · Views: 60

IMG_3400.webp1.8 MB · Views: 60

Ajones880

Well-known member

Updates.. I ordered an OCHO Fab steering kit. And a (similar to this) 4L80 to Ford Reid case transmission from Maximum Transmission.

Attachments

jackbeaugureau

Member

- Joined

- Mar 13, 2025

- Messages

- 16

badass dude! getting a ton of inspo for the front end of my truck haha

Ajones880

Well-known member

Some updates! Got the OhhCho fab steering cross member installed, mounted the power steering reservoir, picked up a PSC ported steering gear from my favorite dudes over at Desolate Motorsports, and grabbed a Howe steering cooler from Kartek.

Moving slowly, but surely..!

Moving slowly, but surely..!

Attachments

Ajones880

Well-known member

Yes, very straightforward. Installation was a breeze.!How's the fitment and install for that crossmember? Pretty strait forward?

Ajones880

Well-known member

Tree trunk

Well-known member

Very cool

Correct me if I am mistaken but you have a 4.5” over beam?

If so, did you ever consider going up to ohhcho’s 6” over beam with the fabricated go fast hubs?

6” is pretty damn wide

Correct me if I am mistaken but you have a 4.5” over beam?

If so, did you ever consider going up to ohhcho’s 6” over beam with the fabricated go fast hubs?

6” is pretty damn wide

Ajones880

Well-known member

Yes, 4.5” over beams. And yes, I have considered the race beam kit at 4.5” over. It’s currently on the list of upgrades, just not at the moment.Very cool

Correct me if I am mistaken but you have a 4.5” over beam?

If so, did you ever consider going up to ohhcho’s 6” over beam with the fabricated go fast hubs?

6” is pretty damn wide

UR_Mawm69

Well-known member

IT MADE ME SOOOOOOOOOOOOO HAPPY TO SEE THIS NAME POP UP UNDER THE "WHAT'S NEW" TAB!!!!!!!!!!!!!

soooooooooooooo much looooooooooooovvvvvveeeeeeeeeeeeee for this thing all the way back from the DR days!!!!!!!

soooooooooooooo much looooooooooooovvvvvveeeeeeeeeeeeee for this thing all the way back from the DR days!!!!!!!

Ajones880

Well-known member

IT MADE ME SOOOOOOOOOOOOO HAPPY TO SEE THIS NAME POP UP UNDER THE "WHAT'S NEW" TAB!!!!!!!!!!!!!

soooooooooooooo much looooooooooooovvvvvveeeeeeeeeeeeee for this thing all the way back from the DR days!!!!!!!

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 31

- Views

- 2K