84projectFORD

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 339

most of the parts for the beams have showed up. probably run stock steering for a while. Got 5.13 gears, new carrier so the 5.13's work, spartan locker, mile marker stainless hubs (currently has auto hubs), new mevotech ttx ball joints (lets see how these hold up compared to napa blue boots), new seals for the diff and wheel bearings, and some other odds and ends.

in the mean time, headed to Moab this week so brought the tracker in for some prep.

Changed the oil/filter

Cleaned/oiled air filter

New control arm bushings (because why not when you are gunna cut this front end out anyhow lmao)

New fuel filter

And changed the 3500 mile old oil pressure sensor that’s leaking for another new one

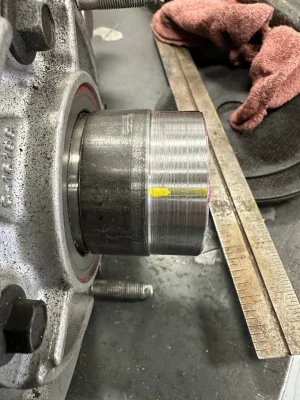

The bushings were a chore and were flat wore out lol

Couldn’t use my ball joint press to push them out due to the flange on one side being the same size as the arm. Found the air hammer with a chisel end made quick work of cutting the flange off. Then I could use the ball joint press to get them out. To put the new ones in, I had to heat up the arm before pressing them in. Fuckers were tight!

Had my helper out there with me today too. He helped tighten up the air filter, get me dropped tools and worked on his “dump truck” lol. yes, this child has no shoes on, hes also the same one that will continue to run around with a god damn cholla in his foot as well.

in the mean time, headed to Moab this week so brought the tracker in for some prep.

Changed the oil/filter

Cleaned/oiled air filter

New control arm bushings (because why not when you are gunna cut this front end out anyhow lmao)

New fuel filter

And changed the 3500 mile old oil pressure sensor that’s leaking for another new one

The bushings were a chore and were flat wore out lol

Couldn’t use my ball joint press to push them out due to the flange on one side being the same size as the arm. Found the air hammer with a chisel end made quick work of cutting the flange off. Then I could use the ball joint press to get them out. To put the new ones in, I had to heat up the arm before pressing them in. Fuckers were tight!

Had my helper out there with me today too. He helped tighten up the air filter, get me dropped tools and worked on his “dump truck” lol. yes, this child has no shoes on, hes also the same one that will continue to run around with a god damn cholla in his foot as well.