smokeysevin

Active member

- Joined

- Mar 7, 2023

- Messages

- 236

What shift kit are you going to use?

Sean

Sean

On the headers, use oem gaskets for the block to header connection.

I have some stainless header flanges where the cats connect already cut if you want them. They are 3/8" or 1/2" thick iirc.

I really like the remflex gaskets for that flange. Ill see if I can find the part number I used.

Sean

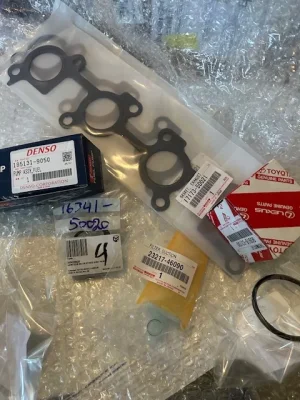

V bands are the way to go.View attachment 43222

Toyota gaskets already purchased and ready to go. I’m going to have to chop off the 3 bolt flange and doing a weird extension to clear the rack/steering shaft. I’m probably going to to do V bands instead of flanges. Thanks though.

Sometimes 2 min worth of cutting and welding saves hours of work.Straight through the core support NICE!

Did you get an OE fit 3 core rad or custom mounting a generic one?Sometimes 2 min worth of cutting and welding saves hours of work.

I may have to modify the core support/radiator support to mount the new radiator/fan combo anyways. Cutting that one little support bar made so much more room

for motor swapping activities. The V8 will have to go in and out at least twice, probably more.

The new 3 core radiator is real thick compared to the OE one. I don’t want any cooling issues.

A 3 core designed for a diesel surf. The version we don’t get in the states. The inlet/outlet are in the correct spots for the V8 and it bolts into the core support. I don’t know if they will be enough room between the front of the motor and the new radiator to fit a fan. The Camaro ZL1 fan I got is pretty shallow, but this is a lot of engine in a little truck.Did you get an OE fit 3 core rad or custom mounting a generic one?

All good. My response was reaffirming what we both said. Sometimes internet talk without facial expressions or inflection can be misinterpreted.Oh I wasn’t dissing it I think it’s smart and the right way to go.