BROmanian

Well-known member

- Joined

- Aug 16, 2023

- Messages

- 173

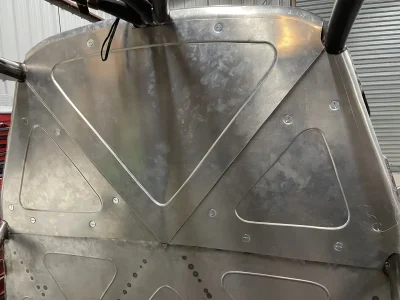

Designed this super intricate (not) fuel tank made out of 1/8 5052 aluminum, cut it on the laser and bent it on the bender. Lots of welding but after a few hours we have a functioning fuel tank. Fits like a glove, the bottom frame is 1.5 x 1.5 angle iron that I welded to the frame. Top will have removable tubes.