You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Local Legend Not much left Tacoma left... 4500 koh build

- Thread starter Hambone

- Start date

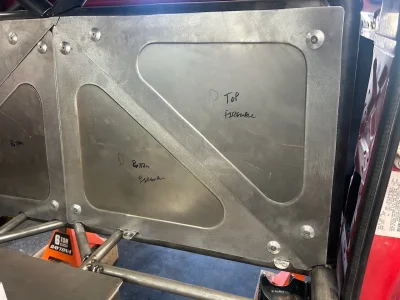

Made some tabs out of 1/8 with 1/4-20 stainless press in nutserts. Called for a 3/8 hole which I did but some push out so I put a tac on them. Starting tabbing out the panels which is a lot of work but got most the driver side panels done. I made 24 tabs and only have 5 or 6 left. Pretty happy with the look

My dad’s here for a few days and we are getting things done. Steering is in minus one link between 2 u joints. Also got the brake pedal mounted. Few more tubes in the rear. Didn’t like the summit radiator I got so holding off on mounting that while I wait for a griffin one to show up. Got the power steering cooler mounted in the front as well.

got more stuff done before my dad left. We got the trans cooler in. He got a bunch of tube in the rear and I got the gas pedal in and fit a few tubes in the subframe to brace the upper rear links. Minus an upper tube for the radiator and a lower tube over the tire, and some gussets in the front engine cage, between the roof bar and a pillar, and between the rear upper shock mounts, I think the tube work is done. The tubes sticking up off the rear near where rhe axle bumps are to keep the tire from sliding forward. There’s one set of dead tubes where the rear axle bumps but didn’t have much of a choice. Axle bumps so high it screwed up my plans to run them to the center under the fuel cell.

Overall happy with all the work. The air filter is way bigger than I expected so it’ll mount between the seats. Just need to find some 4” tube that’s reasonably priced. Ill end up making a dash that comes towards me as everything is to far to reach switch panel wise.

A lot of work left but feeling like I’m getting a lot done. Going to focus on finishing the gussets and tubes so all I have left after that is bumpers. I’ll cap everything that needs capped and then probably move onto a dash.

Overall happy with all the work. The air filter is way bigger than I expected so it’ll mount between the seats. Just need to find some 4” tube that’s reasonably priced. Ill end up making a dash that comes towards me as everything is to far to reach switch panel wise.

A lot of work left but feeling like I’m getting a lot done. Going to focus on finishing the gussets and tubes so all I have left after that is bumpers. I’ll cap everything that needs capped and then probably move onto a dash.

Think I got the last of the tubes in the rear and the rear bumper done. The interwebs told me the bumpstops would rip out of the frame so ran two tubes down that the bump can will weld to the back of.

Few other gusset tubes and some side pieces around the tire to give it a more complete look and a rear bumper. A 37 should sit just inside of it. It’s kicked up about 8*

Few other gusset tubes and some side pieces around the tire to give it a more complete look and a rear bumper. A 37 should sit just inside of it. It’s kicked up about 8*

Welded out the rear of the truck the best I could. I’m hoping when the body comes off I can roll it on the sides to do the bottoms instead of laying on my back. Got everything capped and got the radius tube gussets I want in on the back and front and got the ones for in the cab cut but I’ll wait till I weld all that out. And then milled the wilwood calipers ears to center the rotor.

This bolt got cut shorter after the picture.

This bolt got cut shorter after the picture.

Finished welding the radiator mount. There’s two neighbor hood kids that asked to learn to weld and fabricate so they’ve come over a few days. Told them I’d save the wing for them to practice welding on since it’ll get ground smooth and blended. Finished the rear bumpstops and some other welding including the strike pad for the bumps. They are a little narrow so I’ll add another piece.

Been practicing tig welding. Torch angle is the main thing I feel I have issue with which is causing me to have issues with the filler rod and moving to slow. Had lots of good suggestions and no shame in posting. Decent progress for just 3-4 hours of practice.

First picture is some of the first one. Second set of coupons are after some suggestions. 3rd set is 3/16 to .120 wall tubing. I struggled with that and the heat and filler.

First picture is some of the first one. Second set of coupons are after some suggestions. 3rd set is 3/16 to .120 wall tubing. I struggled with that and the heat and filler.

Tree trunk

Well-known member

I usually blame the neighbor kids when I put down some bad welds

I’m sure you will get in the groove with tig welding in no time

I’m sure you will get in the groove with tig welding in no time

Been getting ready for tacos on the rubicon next week so not much progress. Got some double shear steering done. Just need to do the passenger side. And welded and capped the front upper shock mounts

And finally got harnesses in the crawler.

And finally got harnesses in the crawler.

Pictafiedesign

Well-known member

- Joined

- Jul 11, 2023

- Messages

- 274

I've found that just saying "one" in my head over and over while tig welding gives me the right speed to not make anything too hot. Then it's just repetition after that lol.

DesertGoat

Well-known member

I'm no magician tig welder but a couple of people gave me some tips that have helped me a ton. maybe they'll help you out

1 - sharp tungsten matters more than your ability

2 - set the welder up such that the max amps is just what you need. ~1 amp per thousandth of thickness for fillet welds. Then just keep the pedal floored for the whole weld - this keeps your heat consistent. You'll need to modulate the pedal for corners, starts & stops still.

1 - sharp tungsten matters more than your ability

2 - set the welder up such that the max amps is just what you need. ~1 amp per thousandth of thickness for fillet welds. Then just keep the pedal floored for the whole weld - this keeps your heat consistent. You'll need to modulate the pedal for corners, starts & stops still.

Thanks for the tips. I’ve been good about keeping the tungsten sharp and cleaning it if I dip it.I'm no magician tig welder but a couple of people gave me some tips that have helped me a ton. maybe they'll help you out

1 - sharp tungsten matters more than your ability

2 - set the welder up such that the max amps is just what you need. ~1 amp per thousandth of thickness for fillet welds. Then just keep the pedal floored for the whole weld - this keeps your heat consistent. You'll need to modulate the pedal for corners, starts & stops still.

I started with the welder at the max amps needed and had a ton of people tell me to up the amps to get the puddle formed faster. Which that helped but I still feel like I need the pedal maxed out no matter the amps to keep the puddle moving. I’ll lower the amps again and try it that way just to see if that helps

Got the passenger double shear done and worked on the pitman arm some. Cycled the suspension to make sure the heims don’t bottom out so fully weld that tomorrow. Picked up some 1.5x.25 wall dom and made the tie rods/draglink and panhard and milled some flats in them for a wrench. Not made for a specific size to prevent taking to much material so I’ll just use a crescent wrench.

Trying to wrap up as much stuff on the outside as I can before starting a new task like the fuel cell filler or something else

Trying to wrap up as much stuff on the outside as I can before starting a new task like the fuel cell filler or something else

Similar threads

- Replies

- 10

- Views

- 263

- Replies

- 10

- Views

- 1K

- Replies

- 0

- Views

- 475