4lowlance

Well-known member

- Joined

- Apr 17, 2022

- Messages

- 112

I know these old 90s frames need to flex.

If you don’t let them flex, you better make them stiff.

I have a cab cage with no frame tie in. Original design was just to protect the cab from shaking apart and create strong mounting points

I had a bed cage that was relatively strong.

My f150 frame cracked right near the rear bump stops. I hear it’s a common spot because the C is smallest there.

I assume my bed age held the center of the frame forcing the rear to flex more than normal.

I plated the frame from the cab back. Welded up the crack, and added an X inside the frame to reduce lateral shimmy/shake.

I’m now worried with the rear quite stiff, I’m going to induce cracking in other places.

I need to tie my bed cage into my cab cage, and my cage to the frame to disperse energy.

I put a lot of miles on my truck and it’s very quiet and comfortable inside. I have new door seals, new door strikers, dynamat everywhere. Headliner, lots of insulation ect. My truck really drives nice and tight and quiet at 70mph with the AC and cruise on.

I’m looking for advice on the best way to tie my bed cage to my cab cage, below the rear window.

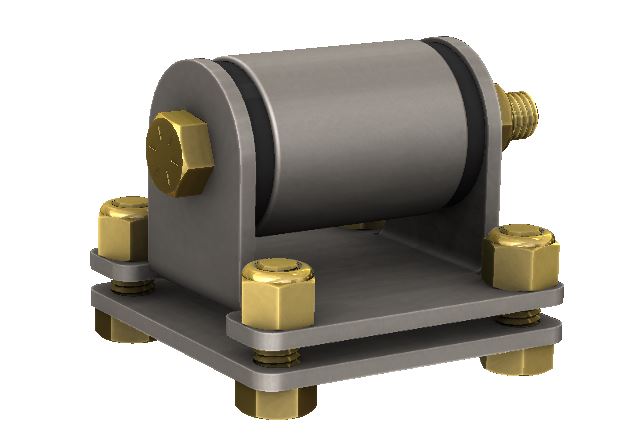

See pictures of my plan. I will use a sleeve/poly bushing to isolate the cab from the frame mounted bed cage.

Tips? Ideas? Am I going to be disappointed with the noise no matter what I do?

If you don’t let them flex, you better make them stiff.

I have a cab cage with no frame tie in. Original design was just to protect the cab from shaking apart and create strong mounting points

I had a bed cage that was relatively strong.

My f150 frame cracked right near the rear bump stops. I hear it’s a common spot because the C is smallest there.

I assume my bed age held the center of the frame forcing the rear to flex more than normal.

I plated the frame from the cab back. Welded up the crack, and added an X inside the frame to reduce lateral shimmy/shake.

I’m now worried with the rear quite stiff, I’m going to induce cracking in other places.

I need to tie my bed cage into my cab cage, and my cage to the frame to disperse energy.

I put a lot of miles on my truck and it’s very quiet and comfortable inside. I have new door seals, new door strikers, dynamat everywhere. Headliner, lots of insulation ect. My truck really drives nice and tight and quiet at 70mph with the AC and cruise on.

I’m looking for advice on the best way to tie my bed cage to my cab cage, below the rear window.

See pictures of my plan. I will use a sleeve/poly bushing to isolate the cab from the frame mounted bed cage.

Tips? Ideas? Am I going to be disappointed with the noise no matter what I do?