MAY 13 2025

I was able to get some time in the garage after work, i wanted to get the front end pulled apart to start the prep. I havent done shit with it since the install 2 years ago as far as maintenance, honestly there is 3 desert trips and about 6k miles on it since the install but i figured i might as well prep to see how shit is holding up.

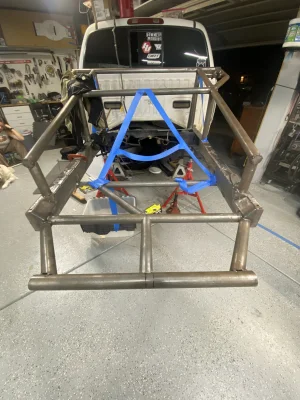

PULLED IN READY TO GO

View attachment 37774

Visual inspection was good other than the upper control arm to spindle bolt had a shit ton of surface rust that will be getting changed out to a grade 8 unit now to tear it down.

View attachment 37775

I got the driver side all stripped off besides the lower thinking i would keep them on to get a ball park length for making my tie rods with heims. Come to find out the lowers are not going to help me at all, i will need to make tie rods when its all going back together.

View attachment 37776

next on the list will be to pull the lowers and steering rack, then start with the upgrades. I have solo motorsports cam tabs that i have pictured earlier in the thread i need to install those, i have plate from SHP fab out of corona to plate the crossmember where the rack bolts onto to hopefully keep the rack from ripping the mounting material.

I did find when pulling my upper control arm that the bolt on the driver side is bent, do any of you Toyota guys know if i can buy a grade 8 bolt

for up there. Im also looking to run the total chaos lower uniball conversion, just not sure its worth the 1000$!! Other than that everything looks as it should especially with only 6k miles.