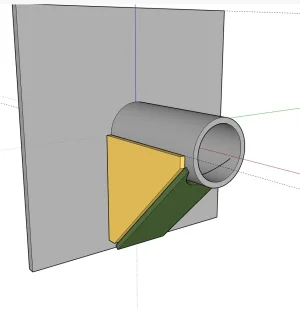

You’re right that you have to learn sometime, but when it comes to building or installing a critical part such as suspension you should really leave that to someone more capable.

This holds the entire vehicle up, and the quality here really puts you and/or passenger lives at risk in the desert. Off-roading at speed is already a risk, and not something that should be increased by unsafe work. I have seen better quality work fail in off-road conditions.

Please do not take this offensively, but I really think you need to step back and take a look at some other trucks, and the steps that people take to make them as structurally sound as they can.

Practice welding, build some shit outta scrap, build a fab table, or bumpers. Work your way up to something like this.

Budget build or not, it should be safe.