This will be my third attempt at ruining a perfectly good Toyota, but my first go at it with some actual (albeit small) funding and proper tooling. Having had a fully caged 92 pickup and it not giving me any issues chassis wise, I knew I wanted to stick with the 89-95 platform. I am also a believer in more people more fun so I started looking for 2nd gen 4runners.

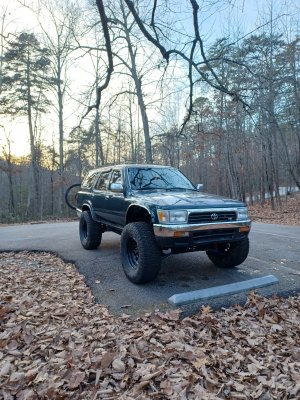

And one day this green machine graced my marketplace for $600![20220911_095002[1].jpg 20220911_095002[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4653-f293f2182337a2183eaba51b1955c391.jpg?hash=8pPyGCM3oh)

![20220910_135022[1].jpg 20220910_135022[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4654-a7b08791f4bd2c0abf39dc5aced3f12f.jpg?hash=p7CHkfS9LA)

Ole girl is a 1994 4x4 auto 4runner with a blown 3.0 that the prior owner had half torn into. I decided that I didn't want to deal with someone else mess and promptly ripped that thang out. I luckily found a 94 t100 with questionable history and a good 3.4 in it for $500:

![20220912_171940[1].jpg 20220912_171940[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4655-9061d5f4ef3515bfe4111834c3295cc3.jpg?hash=kGHV9O81Fb)

![20220915_184518[1].jpg 20220915_184518[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4656-c60976fbffde27ae3cce99a55f749281.jpg?hash=xgl2-__eJ6)

I had a wheeling trip planned two weeks out, so I started thrashing on the 3.4 swap. In total, including the t100, the swap cost me around $700. It was a lot of straightforward work and a bit of headache when trouble shooting the wiring situation.![20220918_171121[1].jpg 20220918_171121[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4657-c32d7c253da99d6287283beaea638c86.jpg?hash=wy18JT2pnW)

![20220922_210800[1].jpg 20220922_210800[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4658-e44b141ec2c73dc716079e6480ba7548.jpg?hash=5EsUHsLHPc)

![20221003_084505[1].jpg 20221003_084505[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4659-3d32ff34e1abeb0d03b74f6b95126a9f.jpg?hash=PTL_NOGr6w)

![20221003_160711[1].jpg 20221003_160711[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4660-c7819dd0f91e8b897da029efe6f9d8de.jpg?hash=x4Gd0Pkei4)

And one day this green machine graced my marketplace for $600

![20220911_095002[1].jpg 20220911_095002[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4653-f293f2182337a2183eaba51b1955c391.jpg?hash=8pPyGCM3oh)

![20220910_135022[1].jpg 20220910_135022[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4654-a7b08791f4bd2c0abf39dc5aced3f12f.jpg?hash=p7CHkfS9LA)

Ole girl is a 1994 4x4 auto 4runner with a blown 3.0 that the prior owner had half torn into. I decided that I didn't want to deal with someone else mess and promptly ripped that thang out. I luckily found a 94 t100 with questionable history and a good 3.4 in it for $500:

![20220912_171940[1].jpg 20220912_171940[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4655-9061d5f4ef3515bfe4111834c3295cc3.jpg?hash=kGHV9O81Fb)

![20220915_184518[1].jpg 20220915_184518[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4656-c60976fbffde27ae3cce99a55f749281.jpg?hash=xgl2-__eJ6)

I had a wheeling trip planned two weeks out, so I started thrashing on the 3.4 swap. In total, including the t100, the swap cost me around $700. It was a lot of straightforward work and a bit of headache when trouble shooting the wiring situation.

![20220918_171121[1].jpg 20220918_171121[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4657-c32d7c253da99d6287283beaea638c86.jpg?hash=wy18JT2pnW)

![20220922_210800[1].jpg 20220922_210800[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4658-e44b141ec2c73dc716079e6480ba7548.jpg?hash=5EsUHsLHPc)

![20221003_084505[1].jpg 20221003_084505[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4659-3d32ff34e1abeb0d03b74f6b95126a9f.jpg?hash=PTL_NOGr6w)

![20221003_160711[1].jpg 20221003_160711[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4660-c7819dd0f91e8b897da029efe6f9d8de.jpg?hash=x4Gd0Pkei4)

![20221009_132611[1].jpg 20221009_132611[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4661-fdad306591769f5cdd67a4f2d9c01a6a.jpg?hash=_a0wZZF2n1)

![20221008_123624[1].jpg 20221008_123624[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4662-a98d3aab13a1e526e273a439c00dafba.jpg?hash=qY06qxOh5S)

![20220920_065514[1].jpg](/data/attachments/4/4663-49839461e1923db7b91d5178b1ff3b09.jpg?hash=SYOUYeGSPb)

![20221025_145704[1].jpg](/data/attachments/4/4664-5053b28ac2ebaa1caca79185141c2c37.jpg?hash=UFOyisLrqh)

![20221125_085816[1].jpg 20221125_085816[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4668-db56a6744367668e6bb44db897d12028.jpg?hash=21amdENnZo)

![20221125_104706[1].jpg 20221125_104706[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4667-f41b859c0d0542d649cc9d2ab2783ec1.jpg?hash=9BuFnA0FQt)

![20221125_124614[1].jpg 20221125_124614[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4666-018c90a72927bce2402f97d1a576d64c.jpg?hash=AYyQpyknvO)

![20221111_173902[1].jpg 20221111_173902[1].jpg](https://forum.badlinesgoodtimes.com/data/attachments/4/4665-4738f59e71b1bab8f7b43a7e76b686f9.jpg?hash=Rzj1nnGxur)