My name is Van Syverud I co own LSK Suspension. I used to love these build threads back in the day and Wally asked me a while ago to go on here and do something like this. I've got the same issue we all do and start projects before finishing old ones. I also have a 95 Bronco in progress over at Richer Racing with a bunch of Ocho Fab parts and a Ford "godzilla" 7.3, 6R80 trans getting linked and caged. This is kind of a side quest truck. Its a "budget" build. Should be a great truck to drive down the highway, tow the bronco and possibly put a 4 wheel camper/GFC in the back at some point. The truck is a 2002 Silverado 1500HD I traded a long travel kit for. Its been in AZ its whole rough life. But its got a LQ4 and a 4L80 and seems to run solid. Here is a picture of the truck after some headlights, a grill and a little bit of cleaning.

The goal originally was a strait axle swap and bolt in shocks in the rear. The issue i had once I started mocking up the SAS in cad is with a ford axle you would be at about a 5" lift for 5" of up travel. It works, and WFO has it figured out decently but I just sold my 2023 Carli Pintop F250 because it worked ok but not great. I then moved on to ttb beams. I scanned my Ocho Fab beams for my Bronco and really a similar issue arises. You basically need to change the driver side frame rail from the cab forward and also the pivot for the passenger side beam was in the oil pan. Its possible really to do it right means a very in depth project similar to the Bronco.

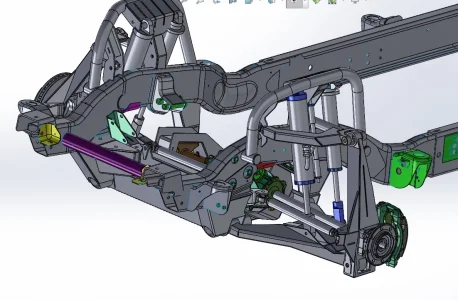

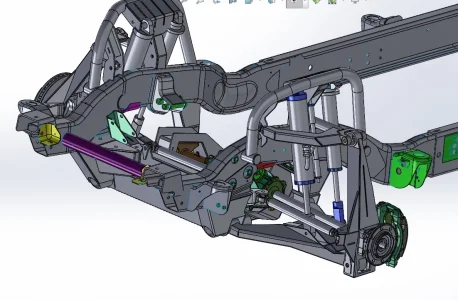

So I went down the rabbit hole of designing a new A- Arm Front suspension. I actually sell a long travel kit for these. It was designed by my business partner a long time a go. It works but was really tailored to a diesel and fire roads. 8" shocks, 12" of wheel travel. I wanted to run 10" shocks, drop the diff and lower arm pivots to allow for more wheel travel and integrate a fully fabricated steering system that gets rid of the factory idler and takes the load off the box/ pitman arm.

Here is where I ended up on that design. The really cool part about moving the diff and lower pivots around is you can eliminate axel plunge. Which really is the issue most 4x4 long travel kits have trouble dealing with. This has less then .065" of plunge and keeps the RCV inner CVs well within their design tolerances for angle.

So currently the truck is in progress. Spent the end of last week tearing out all the stock components and making it a hover truck. I also designed some bolt in inner fenders for these trucks while I was at it to make fiberglass installation less of a nightmare.

Here it is after hours of plasma cutting and cleaning.

Here is the diff test fitment before welding and rebuilding the diff with 4:88 Gears.

And here is where it sits end of day today with the 39x13.5 BFGs and Meathod 704HDs (trying these due to offset) . Hoping to have the front end installed and cycled in the next week so I can move to the rear spring under cantilever setup.

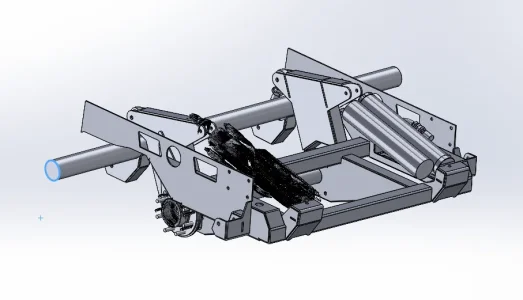

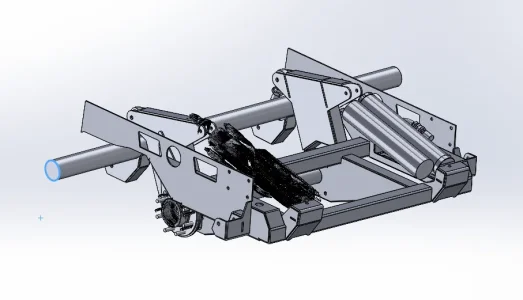

Here is the 3 piece subframe ready to be installed. The back portion unbolts to allow for diff installation, oil pan maintenance, ect.

Should have spindles, Lower Arms, Upper arms and steering ready to be cycled shortly.

The rear will be spring under C85 springs from Deaver with a cantilever style rear suspension using a 14" 3.5 bypasses. Here is a picture of the cad on that. Uses a Ford unit bearing as a pivot and should be able to lock and unlock a 35 spline sway bar.

Should wrap that up after we get that done with the front end.

The goal originally was a strait axle swap and bolt in shocks in the rear. The issue i had once I started mocking up the SAS in cad is with a ford axle you would be at about a 5" lift for 5" of up travel. It works, and WFO has it figured out decently but I just sold my 2023 Carli Pintop F250 because it worked ok but not great. I then moved on to ttb beams. I scanned my Ocho Fab beams for my Bronco and really a similar issue arises. You basically need to change the driver side frame rail from the cab forward and also the pivot for the passenger side beam was in the oil pan. Its possible really to do it right means a very in depth project similar to the Bronco.

So I went down the rabbit hole of designing a new A- Arm Front suspension. I actually sell a long travel kit for these. It was designed by my business partner a long time a go. It works but was really tailored to a diesel and fire roads. 8" shocks, 12" of wheel travel. I wanted to run 10" shocks, drop the diff and lower arm pivots to allow for more wheel travel and integrate a fully fabricated steering system that gets rid of the factory idler and takes the load off the box/ pitman arm.

Here is where I ended up on that design. The really cool part about moving the diff and lower pivots around is you can eliminate axel plunge. Which really is the issue most 4x4 long travel kits have trouble dealing with. This has less then .065" of plunge and keeps the RCV inner CVs well within their design tolerances for angle.

So currently the truck is in progress. Spent the end of last week tearing out all the stock components and making it a hover truck. I also designed some bolt in inner fenders for these trucks while I was at it to make fiberglass installation less of a nightmare.

Here it is after hours of plasma cutting and cleaning.

Here is the diff test fitment before welding and rebuilding the diff with 4:88 Gears.

And here is where it sits end of day today with the 39x13.5 BFGs and Meathod 704HDs (trying these due to offset) . Hoping to have the front end installed and cycled in the next week so I can move to the rear spring under cantilever setup.

Here is the 3 piece subframe ready to be installed. The back portion unbolts to allow for diff installation, oil pan maintenance, ect.

Should have spindles, Lower Arms, Upper arms and steering ready to be cycled shortly.

The rear will be spring under C85 springs from Deaver with a cantilever style rear suspension using a 14" 3.5 bypasses. Here is a picture of the cad on that. Uses a Ford unit bearing as a pivot and should be able to lock and unlock a 35 spline sway bar.

Should wrap that up after we get that done with the front end.

Last edited: