You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Uncle Eddie bronco build

- Thread starter Cgiles01

- Start date

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

Attachments

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

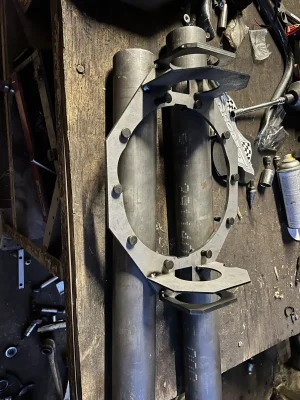

Started welding in the axle so far the face plate is in place and burned to the axle tubes. I started burning the back of it on I do 2 welds per side then let it cool 100%. I do 2 welds a day on it. That way I keep it as straight as I can. It currently sits at 72” tube end to tube end I will need to shorten it some once I decide what hubs ect will go on the ends of it.

Attachments

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

Last edited:

turbomonty

Well-known member

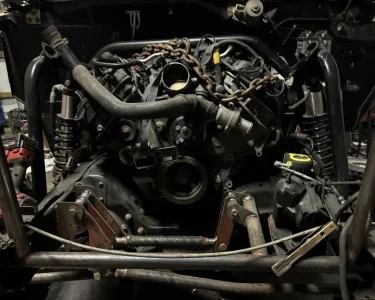

6r80 in the frame

i love 6R80!

what controller and shifter are you going to use?

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

I’m currently stripping a factory harness and will send my pcm out to get it unlocked. And tunedi love 6R80!

what controller and shifter are you going to use?

turbomonty

Well-known member

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

Right on it will have a up shift and down shift button on the steering wheel. I had my coyote swapped raptor set up the same way

turbomonty

Well-known member

very nice

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

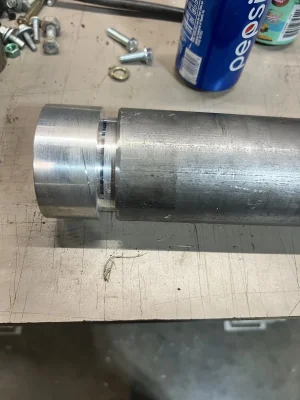

Nice job. I’m getting ready to make my own 9 in housing after prices doubled since I last built one. Where did you get the tubing from and did you run an alignment bar down the tube through your pucks? How did you decide how wide to make the pucks inside the 3rd to butt the axle tube against? Last question is what are your plans for axle seals?This evening I spent some time working on my son’s math. What better way to learn math by machining some parts to finally start building the axle for the bronco!View attachment 15849

Looks awesome

Cgiles01

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 265

I ordered my housing as a kit from a company called Rhoads race cars I think it was u see $300 for everything. As far as the pucks go I pretty much just made them a 3” wide and put 4 per axle tube. I used a alignment bar through it as well. I’m a machinist for a living so coming up with the pucks and alignment bar was easy for me. The company that sells the housing kit also sells a alignment bar kit you can buy also.Nice job. I’m getting ready to make my own 9 in housing after prices doubled since I last built one. Where did you get the tubing from and did you run an alignment bar down the tube through your pucks? How did you decide how wide to make the pucks inside the 3rd to butt the axle tube against? Last question is what are your plans for axle seals?

Looks awesome

Thanks I’ll look them up. I’m planning to cut my own center section and order tubing. I’m a hobbyist machinist at best but making the pucks will be easy. I’ll just need to find an alignment bar.I ordered my housing as a kit from a company called Rhoads race cars I think it was u see $300 for everything. As far as the pucks go I pretty much just made them a 3” wide and put 4 per axle tube. I used an alignment bar through it as well. I’m a machinist for a living so coming up with the pucks and alignment bar was easy for me. The company that sells the housing kit also sells an alignment bar kit you can buy also.

Similar threads

- Replies

- 5

- Views

- 296

- Replies

- 44

- Views

- 1K

- Replies

- 22

- Views

- 385

- Replies

- 22

- Views

- 1K

- Replies

- 70

- Views

- 2K