SaltyMethods

Well-known member

Made it back from our yearly trip. This year was the Arizona Peace Trail. We did the Northern half this year to see what it was all about. Super fun. Rocky in the beginning, smoothed out about half way in the mountains and the last half was a little of both. Hot AF pretty much the whole time. A little bit of mayhem but all-in-all we made it through without rolling, crashing or anyone dying. Success!!

The T-Juan at the meeting point (View Point off the 8-Freeway)

Once we hit the dirt:

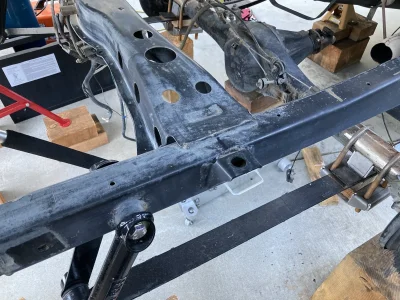

First day, thought I was Ivan Stewart in the washes. Shredded my rear driver's side tire and bent the wheel. Tried to get the tire replaced in Havasu City but the wheel prevented that idea:

Found a pretty dope beer spot. There was a huge key hole opening in a rock cropping:

(going full retard)

One of our friends decided to go 'passenger' when the spotter was telling him to go 'driver!!'. Lots of swear words and choice words were expressed soon after this little predicament. Got him out and to everyone's surprise NOT A GODDAMN SCRATCH on this Rubicon. Lucky bastard.

4Runner decided to drop his rear diff in a hole soon after. More fun words were exchanged:

The purple people eater convention happened to be out on the trail that day:

Should have went 'driver':

Fun little section:

The T-Juan at the meeting point (View Point off the 8-Freeway)

Once we hit the dirt:

First day, thought I was Ivan Stewart in the washes. Shredded my rear driver's side tire and bent the wheel. Tried to get the tire replaced in Havasu City but the wheel prevented that idea:

Found a pretty dope beer spot. There was a huge key hole opening in a rock cropping:

(going full retard)

One of our friends decided to go 'passenger' when the spotter was telling him to go 'driver!!'. Lots of swear words and choice words were expressed soon after this little predicament. Got him out and to everyone's surprise NOT A GODDAMN SCRATCH on this Rubicon. Lucky bastard.

4Runner decided to drop his rear diff in a hole soon after. More fun words were exchanged:

The purple people eater convention happened to be out on the trail that day:

Should have went 'driver':

Fun little section: