ADSRACINGSHOCKS

Active member

- Joined

- Jan 16, 2023

- Messages

- 79

Steering scrub, what it is and how do you know if it is causing you poor handling or making your steering less than desirable.

There are some false statements and heavy generalizations that come out when discussing this subject lets put them to bed and explain what it is first.

Steering Scrub happens when the path or axis your tire rotates on is not landing on the same point as your tire contact patch.

To have a zero scrub set up you need to have your “KPI” or King pin inclination project a path to the center of your tire contact patch, this will allow the tire to pivot on the center and have as little scrub as possible, we will touch on Akerman in a later post we don’t want to mix up the two.

Your KPI is found by projecting an imaginary line from your upper ball joint or pivot and your lower ball joint or pivot at the spindle or even a real king pin for you old F-100 guys.

Let’s look at some examples since I am a visual creature.

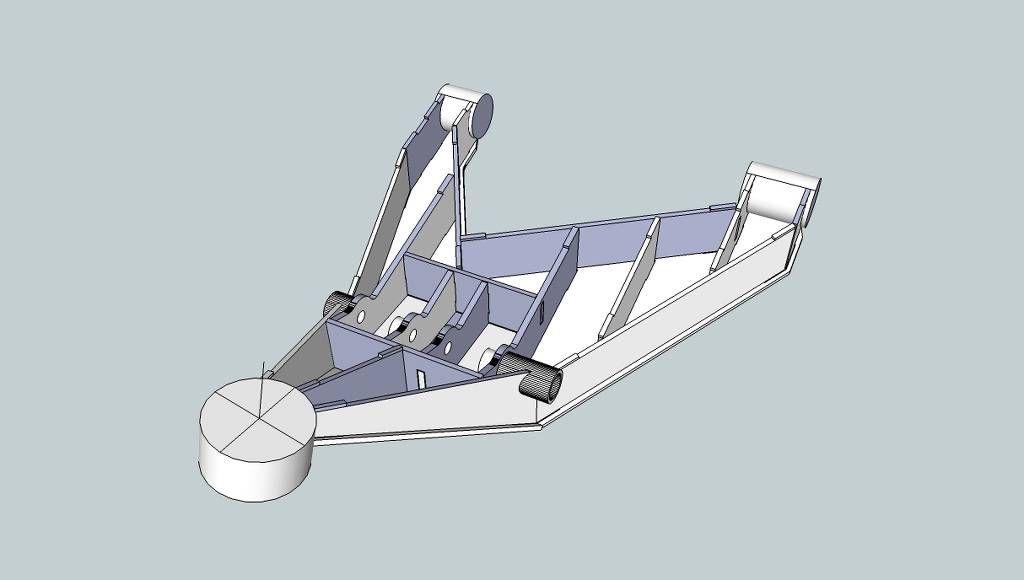

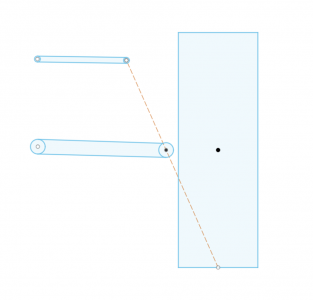

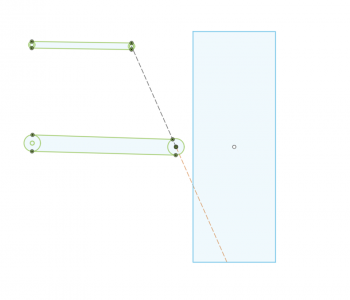

Shown below is a very generic drawing of an A-Arm setup. What we are interested in is the relation of the KPI projection to the center of the tire contact patch. This example would have minimum scrub as the wheel and tire turn on the same axis as the KPI.

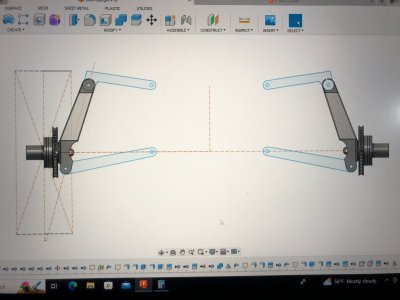

If you think about how certain changes would affect this, we can say that tire size and wheel offset are the main things we can change to make this scrub better or worse. What is the first thing we do to our toys normally? Big ole wheels and tires right, so it was us that made the problem in the first place haha

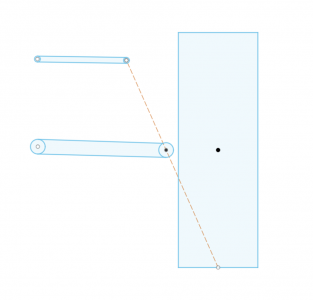

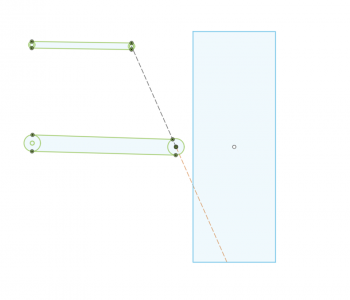

This is the same arm and wheel offset position, but we went from a 40”x13.50” to 35”x12.50” tire as you can see we would need a wheel with a larger/ deeper backspacing to get us back on the same axis and reduce that scrub because we are no longer hitting that center mark.

Each kit or vehicle has a sweet spot to try and hit and you can draw an imaginary line from pivot to pivot to see where you are, most cars and trucks from say 2000 and up have this pretty close but as soon as we put cool wheels and tires on it or aftermarket spindles from a long travel kit we can throw it out of whack in a hurry then we get that poor steering and less than amazing tire wear.

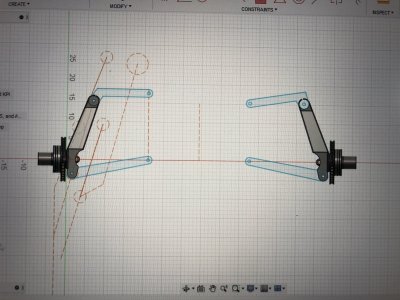

The worst offenders of this issue must be like the example below the pivot axis does not even fall into the tires contact patch at all.

And then we have the overlanders that really get it correct right out of the box. Excuse my squiggly lines but you get the idea here, they are very close to hitting the contact patch dead center if we put stock offset back on this truck and stock size tires it may be perfect.

that really get it correct right out of the box. Excuse my squiggly lines but you get the idea here, they are very close to hitting the contact patch dead center if we put stock offset back on this truck and stock size tires it may be perfect.

Hopefully this is helpful next time you are selecting your wheel offset on your build, there are obviously obstacles on each platform, and sometimes perfect results are hard to come by, with a little bit of home work and foresight you should be able to achieve a very acceptable amount of scrub and have a much easier to drive toy that wont chew up your tires in the mall parking lot.

There are some false statements and heavy generalizations that come out when discussing this subject lets put them to bed and explain what it is first.

Steering Scrub happens when the path or axis your tire rotates on is not landing on the same point as your tire contact patch.

To have a zero scrub set up you need to have your “KPI” or King pin inclination project a path to the center of your tire contact patch, this will allow the tire to pivot on the center and have as little scrub as possible, we will touch on Akerman in a later post we don’t want to mix up the two.

Your KPI is found by projecting an imaginary line from your upper ball joint or pivot and your lower ball joint or pivot at the spindle or even a real king pin for you old F-100 guys.

Let’s look at some examples since I am a visual creature.

Shown below is a very generic drawing of an A-Arm setup. What we are interested in is the relation of the KPI projection to the center of the tire contact patch. This example would have minimum scrub as the wheel and tire turn on the same axis as the KPI.

If you think about how certain changes would affect this, we can say that tire size and wheel offset are the main things we can change to make this scrub better or worse. What is the first thing we do to our toys normally? Big ole wheels and tires right, so it was us that made the problem in the first place haha

This is the same arm and wheel offset position, but we went from a 40”x13.50” to 35”x12.50” tire as you can see we would need a wheel with a larger/ deeper backspacing to get us back on the same axis and reduce that scrub because we are no longer hitting that center mark.

Each kit or vehicle has a sweet spot to try and hit and you can draw an imaginary line from pivot to pivot to see where you are, most cars and trucks from say 2000 and up have this pretty close but as soon as we put cool wheels and tires on it or aftermarket spindles from a long travel kit we can throw it out of whack in a hurry then we get that poor steering and less than amazing tire wear.

The worst offenders of this issue must be like the example below the pivot axis does not even fall into the tires contact patch at all.

And then we have the overlanders

Hopefully this is helpful next time you are selecting your wheel offset on your build, there are obviously obstacles on each platform, and sometimes perfect results are hard to come by, with a little bit of home work and foresight you should be able to achieve a very acceptable amount of scrub and have a much easier to drive toy that wont chew up your tires in the mall parking lot.