You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fiberglass repair

- Thread starter Dirt Yota

- Start date

the bodj

Well-known member

Grind the area back like you’re grinding out a crack to fill with weld. Sand back the gel coat like an inch or two around the crack. Soak fiberglass strips in resin and layer it in there. Start skinny and then do enough layers to get the thickness you need to make it a bit proud of the original gel coat, each time going wider and covering more area. Throw some glass on the backside, too. I usually add a strip of aluminum or something to cross the crack on the backside so it adds rigidity. Sand the front side smooth and paint it white to match your mismatched fenders, because prerunner

Another thing people over look is the least amount of resin the better. They actually make special rollers that are supposed to help push out the resin. Like bodj said the more u can v out the Crack almost all the way through the better the patch will be almost like feathering it out as you go. They also make a mesh woven fiberglass that is similar to carbon cloth that works well too. kitty hair is good when u have to fill or build up superficial stuff. It is pretty strong as well.

Being first go at glass repair is it ok to layer same process @the bodj mentioned above on the back side of fender with minimal glass on front side of glass? Or is it necessary to glass front side of fender? So far I ground out crack and glassed back side real good. Was thinking minimal glass on frontside and some body filler. This is also a repair on top of a previously repaired area lol

smokeysevin

Active member

- Joined

- Mar 7, 2023

- Messages

- 241

You want to grind the crack out so it doesnt keep tearing and show through on the front side. Its almost impossible to make it look good if the crack is still there, you will always have pinholes or a seam.

Sean

Sean

4XForOffroad

Well-known member

Went through some of this myself last couple weeks. Paid a former student and his classmate to paint all my panels like 4-5 years ago trying to help their “drift car fab company” get off the ground but it went insolvent (I guess it was almost inevitable) and they never finished painting them. Luckily for me I got 4 years of free storage out of it when they got into ornamental fab doing railings for patios etc. and these sat in an adjacent cabinet maker’s shop getting covered in sawdust the whole time.

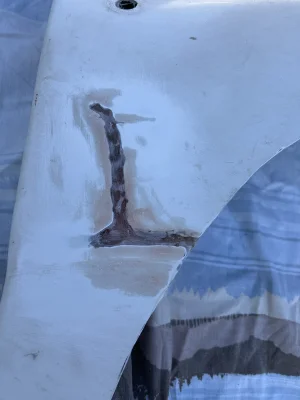

Of course the story didn’t end there as the pictures indicate and when I got them back recently, my friend now in his early 20’s decided to flight test one from the the back of his pickup truck in the middle of the 110 freeway in southern LA when he didn’t ratchet strap them when he should have (and had plenty to use haha). After faithfully driving 2 miles and backtracking on the streets in a now-rescue-mission, he found it injured but in stable condition on the side of the freeway and retrieved it. And of course it was the one side that Fiberwerx made to actually fit the truck right lol.

Anyway I spent a little time watching some videos that gave me enough confidence to think I could not completely screw it up (although I managed to a little regardless).

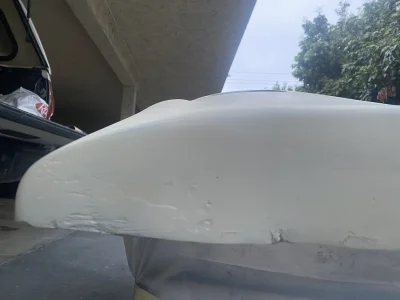

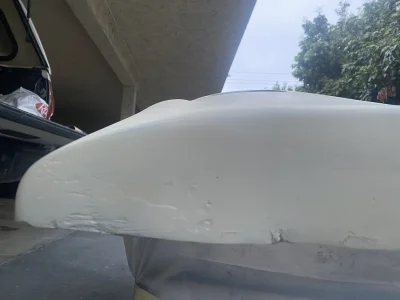

For next time I’m going to get some chopped and 90* weave and a roller to squeeze out the bubbles and maybe thin the resin too. This time around I used chopped mat on the inside and fiber reinforced bodyfiller from JB weld on the outside. I ground out the cracks, but in hindsight I would have done so with something smaller like my dremel than the flap disk I used since it all sands together with the body filler pretty nicely.

https://m.youtube.com/watch?v=ujk-wBQDUSk&t=800s&pp=ygUWRmliZXJnbGFzcyBib2F0IHJlcGFpcg==

https://m.youtube.com/watch?v=l86jZc6E_Z4&pp=ygUdRmlzaCBidW1wIHR5cGVzIG9mIGZpYmVyZ2xhc3PSBwkJsgkBhyohjO8=

https://m.youtube.com/watch?v=yo9sPApHULQ

Of course the story didn’t end there as the pictures indicate and when I got them back recently, my friend now in his early 20’s decided to flight test one from the the back of his pickup truck in the middle of the 110 freeway in southern LA when he didn’t ratchet strap them when he should have (and had plenty to use haha). After faithfully driving 2 miles and backtracking on the streets in a now-rescue-mission, he found it injured but in stable condition on the side of the freeway and retrieved it. And of course it was the one side that Fiberwerx made to actually fit the truck right lol.

Anyway I spent a little time watching some videos that gave me enough confidence to think I could not completely screw it up (although I managed to a little regardless).

For next time I’m going to get some chopped and 90* weave and a roller to squeeze out the bubbles and maybe thin the resin too. This time around I used chopped mat on the inside and fiber reinforced bodyfiller from JB weld on the outside. I ground out the cracks, but in hindsight I would have done so with something smaller like my dremel than the flap disk I used since it all sands together with the body filler pretty nicely.

https://m.youtube.com/watch?v=ujk-wBQDUSk&t=800s&pp=ygUWRmliZXJnbGFzcyBib2F0IHJlcGFpcg==

https://m.youtube.com/watch?v=l86jZc6E_Z4&pp=ygUdRmlzaCBidW1wIHR5cGVzIG9mIGZpYmVyZ2xhc3PSBwkJsgkBhyohjO8=

https://m.youtube.com/watch?v=yo9sPApHULQ

Last edited:

Fenix Motorsports

Active member

My experience with drift car people is they always want everything done as cheap as possible and subsequently, low quality, I assume because they crash their cars every 5 minutes because a lot of them can't actually drive, or at least my nephew can't.............Went through some of this myself last couple weeks. Paid a former student and his classmate to paint all my panels like 4-5 years ago trying to help their “drift car fab company” get off the ground but it went insolvent (I guess it was almost inevitable) and they never finished painting them. Luckily for me I got 4 years of free storage out of it when they got into ornamental fab doing railings for patios etc. and these sat in an adjacent cabinet maker’s shop getting covered in sawdust the whole time.

Bumping this

Hoping to start on some Fiberglass work here soon. Front corner of fenders that meets the hood, old fiberglass mounting holes, etc. Big one is adding structure next to the tail lights on the inside where the tailgate use to slide… thinking a piece of thin aluminum as the base and then fiberglass that. Any input on dos or donts? Already some good info in here

Hoping to start on some Fiberglass work here soon. Front corner of fenders that meets the hood, old fiberglass mounting holes, etc. Big one is adding structure next to the tail lights on the inside where the tailgate use to slide… thinking a piece of thin aluminum as the base and then fiberglass that. Any input on dos or donts? Already some good info in here

smokeysevin

Active member

- Joined

- Mar 7, 2023

- Messages

- 241

Drill some holes through the aluminum and rough the shit out of it with a carbide burr or something before you try and stick it down so the resin keys through it.Bumping this

Hoping to start on some Fiberglass work here soon. Front corner of fenders that meets the hood, old fiberglass mounting holes, etc. Big one is adding structure next to the tail lights on the inside where the tailgate use to slide… thinking a piece of thin aluminum as the base and then fiberglass that. Any input on dos or donts? Already some good info in here

I like to use a thickener with the epoxy like cabosil or something when attaching it to metal. You can also look at using something like west systems g-flex if you think you want the metal and glass to bend a bit rather than cracking there.

Sean

Similar threads

- Replies

- 10

- Views

- 920