theycallmeWALLY

Administrator

- Joined

- Mar 30, 2022

- Messages

- 1,529

So yesterday when pulling the trans out of the Ranger I had 3 seized up bolts that hold the Y-Pipe of the exhaust in place.

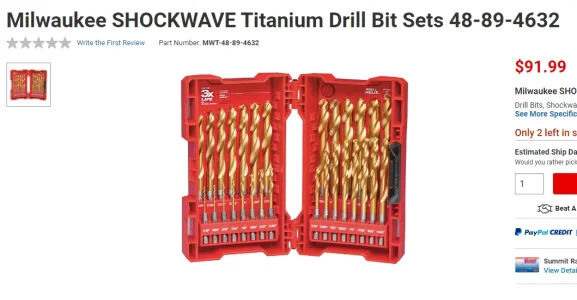

Ended up cutting the bolts and then proceeded to drill them out. I had brand new drill bits and I'm pretty sure I burnt up a few in the process. I tried to go slow use a bunch of cutting oil but it took me like 2 solid hours to get all 3 drilled out.

What I did and please tell me what you would have done differently...

#Trucksaredumb

Ended up cutting the bolts and then proceeded to drill them out. I had brand new drill bits and I'm pretty sure I burnt up a few in the process. I tried to go slow use a bunch of cutting oil but it took me like 2 solid hours to get all 3 drilled out.

What I did and please tell me what you would have done differently...

- Drill small pilot hole all the way through the bolt.

- This drilled through the fasted.

- Then drilled out with a drill bit 3 times the size and continued this process until I was at 7/16

- I tried mixing in some step drill bits but they didn't do $hit

#Trucksaredumb