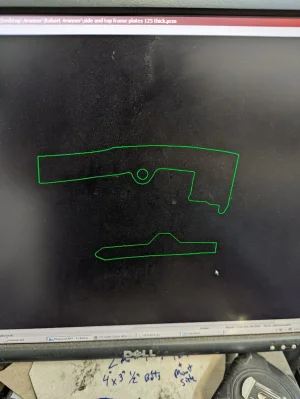

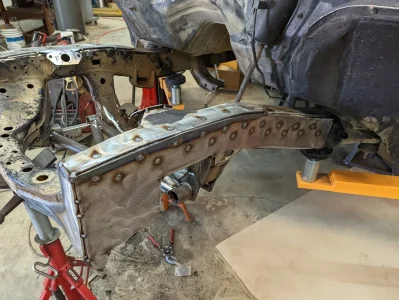

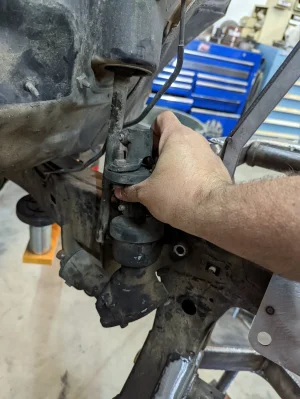

Ok so I am building this is stages for @SoCal4rnr. It's a 3rd gen 4Runner, I believe it's a 96 or 97. It was 4x4 BUT now it's got my TT Motorsports Race kit, with camburg 2.5 front Hubs, a LS 5.3 with 4l80e going in it, Also going to develop a swing steer setup for this thing to run a steering box and ram, eliminate the weak link of rack n pinion, because racecar. So first start to any major project is remove everything that was stock. It rolled into my shop with the 3.4 V6 almost ready to pull and we removed the MCM Fab 4x4 LT kit, which had 2.5 co and 2.5 bypass, front diff and axles were already removed before it came in.

Last edited: