With tidying things up at the rear of the vehicle and moving into mounting the rear bumper, I needed to get the rear lights/antenna/whip mounts finished up. I'd originally built these out when it had the stock bumper on the rear, but with the updated change to the BA rear bumper, I had to make some changes.

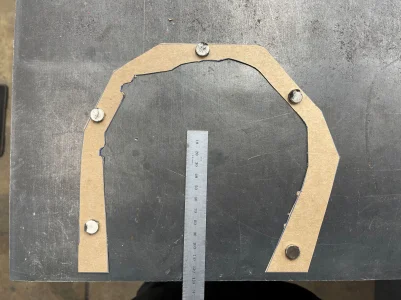

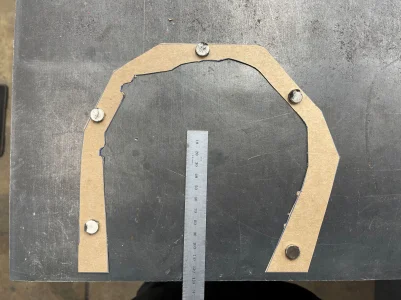

As with most things, chipboard mock-ups are vital and helped me establish the curve just under the taillight.

Getting the initial baseplates tacked up and working inward from there.

Given that these could serve as CB antenna mounts or rear light mounts, I didn't fully trust them hanging off the hatch bumper bolts and decided to build a small support under them. It was at about this time I got the news of the change of bumpers - glad I didn't drill into the OEM bumper haha.

Fast forward like 9 months later, and the bumpers landed and I was sent home with an initial prototype to start chopping up. These are for the 5th gen 4 Runners, so they're about 9 inches wider between the outermost 'wings'; I'd have to cut out the center and get it to sit closer.

Finding the centerline so I can make the cuts and get it to sit closer to the body.

No going back now...it's just metal after all haha!

Got it tacked up, verified fitment and took some more measurements.

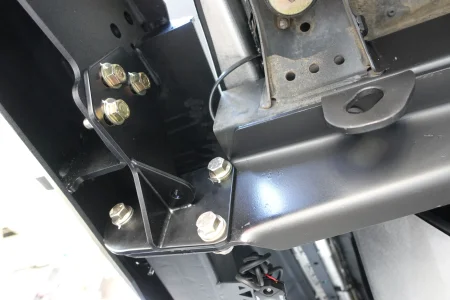

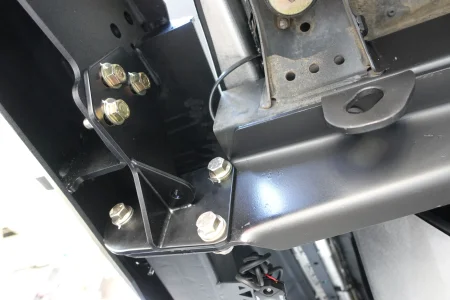

Built out some bumper mounts - with the bumper having opposing slotted holes, I added some in the bracket in order to finalize fitment as close as possible.

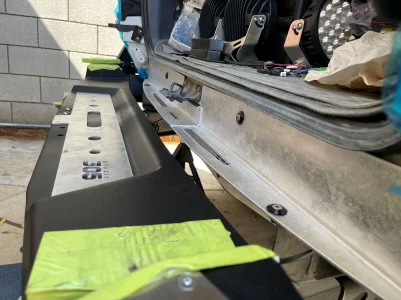

Got the mounts back from powder and got the bumper sitting just right.

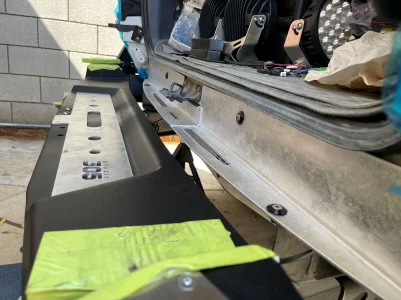

I started roughing out and fitting up a trim panel to bridge the gap between the bumper and the lower latch area. The difference between where the 3rd and 5th gens lie are quite a bit different. Also had a trim panel cut out for the top of the bumper.

At the forward most edge is a slotted bracket that helps brace the front of the bumper. Although pretty stout without it, I opted to add it in so there's minimal deflection up there.

I then added some standoffs on the side of the body and cut/bent up a trim panel to cover and fill the gap a bit better.