You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

88’ Raingutter Ranger

- Thread starter MTSuarez

- Start date

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

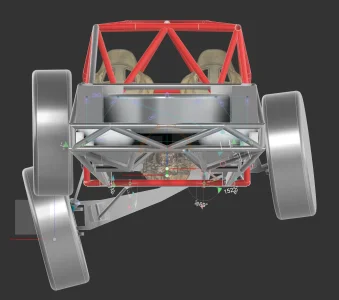

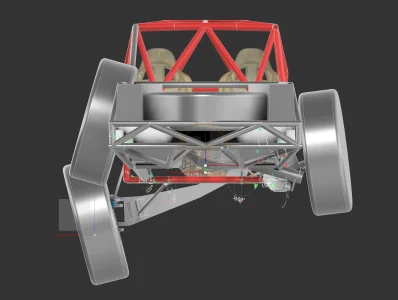

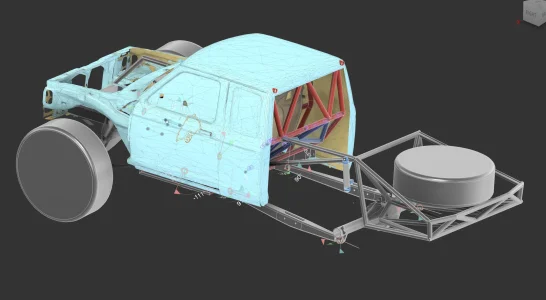

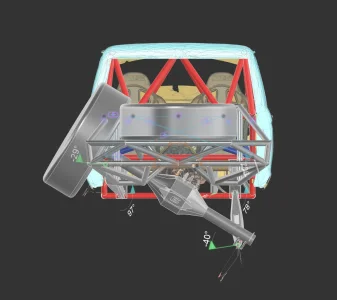

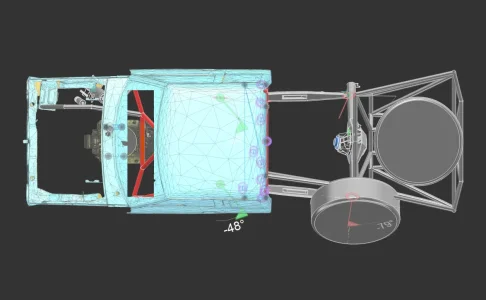

Probably going to start by taking 4" off overall on the cab side of the fuel cell carrier and see where that gets me. Not sure if the angle I put the rear end at is "realistic" or even possible with a sway bar installedPost some pictures, the tire will have some deflection when they get bottomed out

Attachments

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Looks killer, I would add and least 2" from the rear of the diff to the chassis for it to "swing" up or down that will leave room for the diff oil cap and a skid plate.

Yes everything on the chassis is going to be custom.Are you running a custom or prebuilt fuel cell?

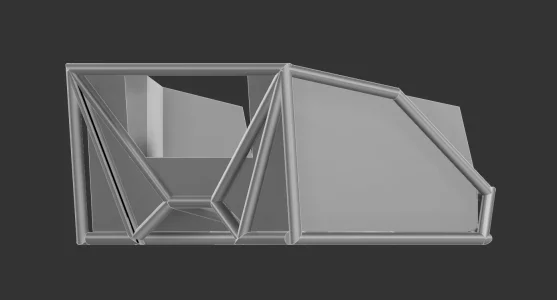

All that clears, the back of the fuel cell indents inboard to clear around the diff as it cycles. May be hard to tell in these photos but it indents 2" inboard

Attachments

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Still not sure on how much articulation this truck will ever see, edited the fuel cell carrier a bit and ended up with just over 6" clearance with the suspension all in line. If it somehow contacts it still, may my bumpstops find mercy.

Attachments

From the drawing, it looks like it is more likely to hit chassis than bump stops.

I took angle measurements a looong time when setting up 2ghetto for cyling. What I found was with a lot of angle the shocks will bottom out before the bump stops even contact the axle. This never happens in real life. I cant remember... but I swear its not as much angle as you would think. I want to say in the 30 range from memory. I can't go find pictures right now because my work firewall blocks the site with geofence.

With that said.. i dont feel like 5-6" is much space!!

I took angle measurements a looong time when setting up 2ghetto for cyling. What I found was with a lot of angle the shocks will bottom out before the bump stops even contact the axle. This never happens in real life. I cant remember... but I swear its not as much angle as you would think. I want to say in the 30 range from memory. I can't go find pictures right now because my work firewall blocks the site with geofence.

With that said.. i dont feel like 5-6" is much space!!

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

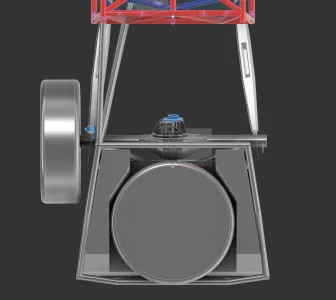

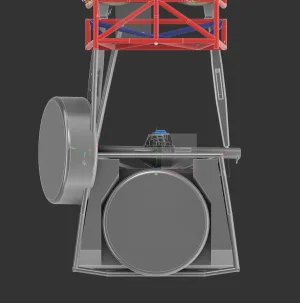

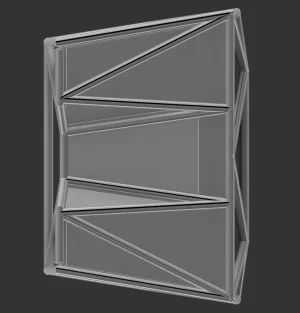

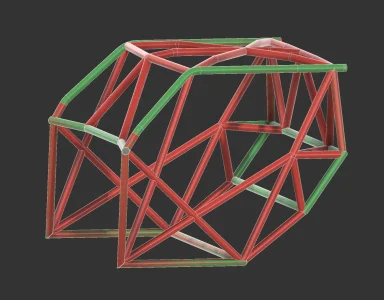

Here is 30 degrees of angle. Don't know about you, but this does not look realisticFrom the drawing, it looks like it is more likely to hit chassis than bump stops.

I took angle measurements a looong time when setting up 2ghetto for cyling. What I found was with a lot of angle the shocks will bottom out before the bump stops even contact the axle. This never happens in real life. I cant remember... but I swear its not as much angle as you would think. I want to say in the 30 range from memory. I can't go find pictures right now because my work firewall blocks the site with geofence.

With that said.. i dont feel like 5-6" is much space!!

Attachments

OK yea... like i said.. its less than you would think!!! I originally typed 20-30.... but then thought.. it's gotta be more than 20. I just checked photos. And just thought this too. What is max misalignment of the heim joints. Cant be more than that! lol

Pretty sure it never does either of these below: You can see how shock is totally bottomed out at 24 and bump isnt even close to hitting

I have pics at 18*

and 24*

Pretty sure it never does either of these below: You can see how shock is totally bottomed out at 24 and bump isnt even close to hitting

I have pics at 18*

and 24*

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

G

Awesome thank you! Did you run a sway bar at all? And if so how much did that limit that articulation you were seeing?OK yea... like i said.. its less than you would think!!! I originally typed 20-30.... but then thought.. it's gotta be more than 20. I just checked photos. And just thought this too. What is max misalignment of the heim joints. Cant be more than that! lol

Pretty sure it never does either of these below: You can see how shock is totally bottomed out at 24 and bump isnt even close to hitting

I have pics at 18*

and 24*

the bodj

Well-known member

Thankfully if you're that articulated the suspension isn't usually moving fast, so bumping the shock like that isn't too bad (especially with the foam shaft bumps). But it's for that reason that I like mounting my bumpstops as close to inline with the shocks as I can (within reason)

Flexed out. It actually goes more but I forgot the driver tire was still on in this picture, so that side could droop further

Flexed out. It actually goes more but I forgot the driver tire was still on in this picture, so that side could droop further

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Guess my current thought is making a bad transition from one section to another and my rear end gets put into heavy articulation, even if only for a second. I’m looking at other trucks with wider rear ends and it doesn’t look like the clearance is any better than mine. Think I’m just going to do a full mock up of my rear end without a sway bar and see what components max out during articulation and at what angles.Thankfully if you're that articulated the suspension isn't usually moving fast, so bumping the shock like that isn't too bad (especially with the foam shaft bumps). But it's for that reason that I like mounting my bumpstops as close to inline with the shocks as I can (within reason)

View attachment 43228

Flexed out. It actually goes more but I forgot the driver tire was still on in this picture, so that side could droop further

View attachment 43229

I didnt have one at first on that truck. And it never did anything wonky.. except roll over. LOL. But it has one now. Definitely run one. It's a world of difference for cornering speed and confidence. (in my opinion of course.)

I can't tell you how much it changes the extreme angles you reach in real world application. It feels significant but I cant put it in numbers because I cant compress shit like that in my driveway/garage. A sway bar is really just a spring that leverages force downward on the opposite corner. I would cycle without one for sure for worst case scenarios.

In case you want an apples to tomatos comparison... I have about 8.5-9" from my bumps to tire bulge.

I can't tell you how much it changes the extreme angles you reach in real world application. It feels significant but I cant put it in numbers because I cant compress shit like that in my driveway/garage. A sway bar is really just a spring that leverages force downward on the opposite corner. I would cycle without one for sure for worst case scenarios.

In case you want an apples to tomatos comparison... I have about 8.5-9" from my bumps to tire bulge.

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

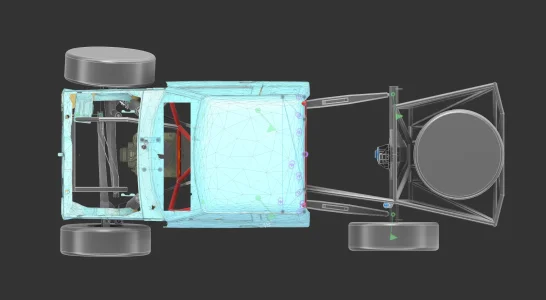

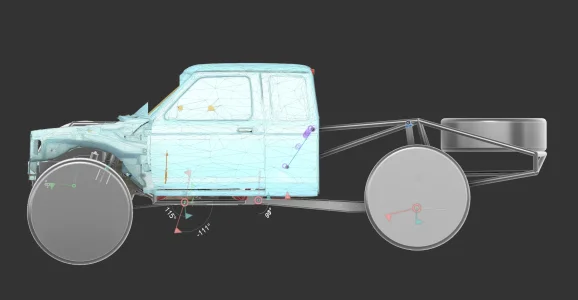

Rad thank you. Mocked up the rear a bit more on the computer and can see the issue where the shocks bottom out before the bumpstop even comes close to contacting. Hard to tell what the limiting factor would be for articulation other than the shocks at this point.I didnt have one at first on that truck. And it never did anything wonky.. except roll over. LOL. But it has one now. Definitely run one. It's a world of difference for cornering speed and confidence. (in my opinion of course.)

I can't tell you how much it changes the extreme angles you reach in real world application. It feels significant but I cant put it in numbers because I cant compress shit like that in my driveway/garage. A sway bar is really just a spring that leverages force downward on the opposite corner. I would cycle without one for sure for worst case scenarios.

In case you want an apples to tomatos comparison... I have about 8.5-9" from my bumps to tire bulge.

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

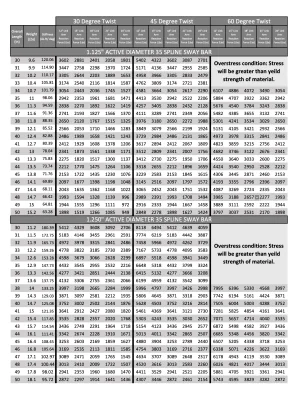

Alright, been a month since I started looking for answers regarding the sway bar and haven't come up with much. Made it out to the Offroad Expo to see what everyone else was running but the numbers were all over the place. SLR Motorsports has their bumpstop 2.5" inches away from the inside tire, while others were at 8-9". Watched Tom's (Deathwish Racing) near miss on his TT, hitting soley on a single rear tire at 80MPH and his tire didn't contact anything (waiting on specific numbers but its packaged pretty tight). Jake with Robert's Custom Trucks was able to send me a graph, which I'll post since someone will make use of it, showing the loads needed to twist bars to a certain degree. Good info, but I'm not smart enough to figure out what the truck would have to do to create a given Load on the sway bar. Still unsure of what angle to mock the rear end up at to start building around it, if anyone has experience with hard impacts and are using a sway bar I'd love to know how much clearance you have at ride height.

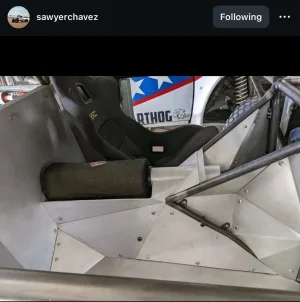

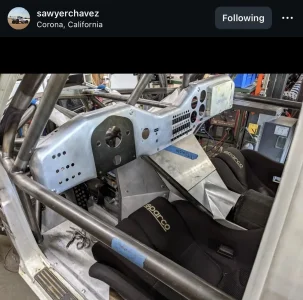

With the Engine being moved back, the amount of space for where my legs will end up is relatively restricted. Mocked up where my tranny would sit, a race seat, and the downtubes that will hold the midplate for the motor. I'm sitting at around 12" of clearance for my feet (between door and midplate tube), its gonna be tight but hoping everything above my calves should have better room. Looking at Jesse Kline or Sawyer Chavez's rangers you can imagine how cramped it might get. Had to redo a good chunk of the cab cage, which I thought was "finalized", to make sure I have the ability to move the seats farther back incase it is worse than I anticipate.

With the Engine being moved back, the amount of space for where my legs will end up is relatively restricted. Mocked up where my tranny would sit, a race seat, and the downtubes that will hold the midplate for the motor. I'm sitting at around 12" of clearance for my feet (between door and midplate tube), its gonna be tight but hoping everything above my calves should have better room. Looking at Jesse Kline or Sawyer Chavez's rangers you can imagine how cramped it might get. Had to redo a good chunk of the cab cage, which I thought was "finalized", to make sure I have the ability to move the seats farther back incase it is worse than I anticipate.

Attachments

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Here's some of the sway bar setups and bumpstop locations/clearance I found

Attachments

-

Screenshot 2025-11-03 at 5.40.04 PM.webp179.2 KB · Views: 30

Screenshot 2025-11-03 at 5.40.04 PM.webp179.2 KB · Views: 30 -

Screenshot 2025-11-03 at 5.40.12 PM.webp226.8 KB · Views: 28

Screenshot 2025-11-03 at 5.40.12 PM.webp226.8 KB · Views: 28 -

Screenshot 2025-11-03 at 5.40.18 PM.webp316.4 KB · Views: 29

Screenshot 2025-11-03 at 5.40.18 PM.webp316.4 KB · Views: 29 -

Screenshot 2025-11-03 at 5.41.25 PM.webp123.2 KB · Views: 31

Screenshot 2025-11-03 at 5.41.25 PM.webp123.2 KB · Views: 31 -

Screenshot 2025-11-03 at 5.41.48 PM.webp87.7 KB · Views: 30

Screenshot 2025-11-03 at 5.41.48 PM.webp87.7 KB · Views: 30 -

Screenshot 2025-11-03 at 5.42.25 PM.webp117.5 KB · Views: 28

Screenshot 2025-11-03 at 5.42.25 PM.webp117.5 KB · Views: 28 -

Screenshot 2025-11-03 at 5.42.48 PM.webp120.5 KB · Views: 28

Screenshot 2025-11-03 at 5.42.48 PM.webp120.5 KB · Views: 28

Pictafiedesign

Well-known member

- Joined

- Jul 11, 2023

- Messages

- 274

I've always understood it as the sway bar needing to be as wide as your lower link pivots. You want the sway bar upper link to run parallel to the lower link in a plan view and as it articulates it should stay as close to 90 as it can be for the majority of motion from a side view. I run a 51" wide 1.125" bar with 20" upper links mine are about 3" from the tire these align with the lower link pivots on the axle. The wider you can get both lower link and sway bar the more stable the rear end will be. Hope this helps, I'm sure it's up for debate but I don't think it articulates as much as you're thinking it will.

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

That's what I was thinking. Pretty sure if that truck articulates 10 degrees it would blast the shrader valve off the bump stop at the very leastMan, that one bump is way close!! must be the 2.5" one. I would think that could hit from looks of it. Does it get beat on? No tire marks?

MTSuarez

Active member

- Joined

- Nov 27, 2024

- Messages

- 88

Thanks for the info Dave I appreciate it. I had talked with Tom over with Deathwish Racing and he had the same offset from inside tire to sway bar as you.I've always understood it as the sway bar needing to be as wide as your lower link pivots. You want the sway bar upper link to run parallel to the lower link in a plan view and as it articulates it should stay as close to 90 as it can be for the majority of motion from a side view. I run a 51" wide 1.125" bar with 20" upper links mine are about 3" from the tire these align with the lower link pivots on the axle. The wider you can get both lower link and sway bar the more stable the rear end will be. Hope this helps, I'm sure it's up for debate but I don't think it articulates as much as you're thinking it will.

Similar threads

- Replies

- 5

- Views

- 318

- Replies

- 36

- Views

- 3K

- Replies

- 13

- Views

- 887

- Replies

- 19

- Views

- 1K