ricky.vazquez

New member

- Joined

- Feb 3, 2023

- Messages

- 17

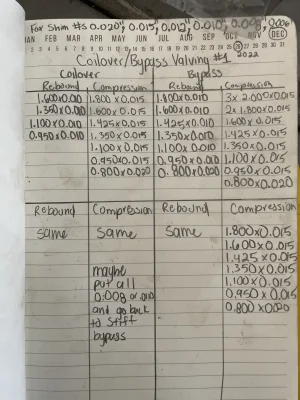

Looking for some guidance. Went from a single 2.5 coilover on the rear of the truck to adding a 3.0 4 tube bypass. Before with single coilover I was running double stack .020 shims and it felt very good only problem was thur very big gouts I would slam bumps. That’s the reason I added these bypasses. I Lowered the compression in the coilover to 0.015 and the bypass had a 321 .015 stack in it for the first test. It was super harsh with all tubes open. So now I took out the 3 biggest shims 2.000 diameter and only left the 1.800 and on. Now I’m thinking I lost all my bump zone. (Haven’t yet to try). I’m taking it out to hammers next week for the week. Going to do some testing and valving. Thinking about putting 0.012s or even 0.010s in the coilover and adding shims back into the bypass to get a good bump zone in. Does that sound about right or am I all fucked up. I’ll figure it out just the thought of driving my truck at hammers with a shitty valved rear is driving me crazy.