You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Turbo Glue Factory: Boosted Colt Build

- Thread starter turbomonty

- Start date

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

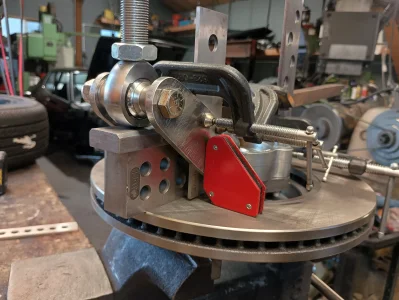

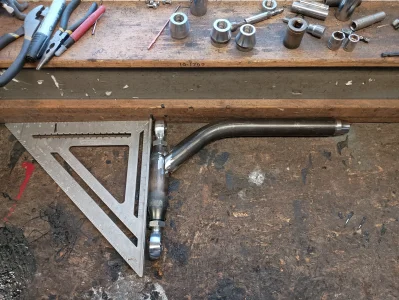

finally got my CNC lathe up and running. made some rod end threaded bushings for the control arms.

i made some over size ones and back bored them for race car function. also took some basic bitch tabs and made them race car too with some .075" deep pattern

i made some over size ones and back bored them for race car function. also took some basic bitch tabs and made them race car too with some .075" deep pattern

Attachments

Last edited:

turbomonty

Well-known member

took a piece of 2" tube to fixture up the tabs all nice and straight like.... probably

i am liking to tig weld these up as you know that shits melted together, very quite and no dam berries all over the fucking place!

i am liking to tig weld these up as you know that shits melted together, very quite and no dam berries all over the fucking place!

Attachments

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

chatbot likes it too!

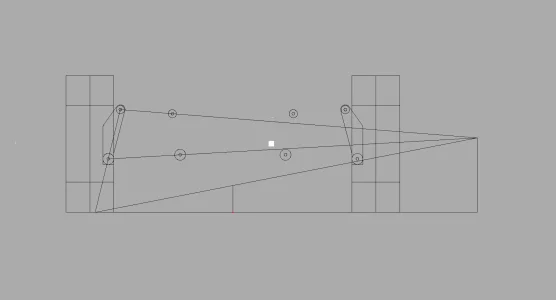

Front track = 52.25"

Half track H = 26.125"

Using your IC:

RC = 13.625 × (26.125 / 70.75)

RC ≈ 13.625 × 0.369

RC ≈ 5.0"

So your front roll center is about 5 inches off the ground.

That’s a very good street / performance number:

Front track = 52.25"

Half track H = 26.125"

Using your IC:

- X = 70.75"

- Y = 13.625"

RC = 13.625 × (26.125 / 70.75)

RC ≈ 13.625 × 0.369

RC ≈ 5.0"

So your front roll center is about 5 inches off the ground.

That’s a very good street / performance number:

- Not too low (no lazy response)

- Not too high (no jacking / weird load transfer)

- Should feel stable and predictable

turbomonty

Well-known member

I am the ship breaker now!

whipped out my harbor freight plasma cutter and with my carnival cruise ship pieces i now have enough 6mm and 3/8" plate to finish the race car

https://www.youtube.com/watch?v=hQVNtXIy3B4

whipped out my harbor freight plasma cutter and with my carnival cruise ship pieces i now have enough 6mm and 3/8" plate to finish the race car

https://www.youtube.com/watch?v=hQVNtXIy3B4

Attachments

Last edited:

turbomonty

Well-known member

turbomonty

Well-known member

turbomonty

Well-known member

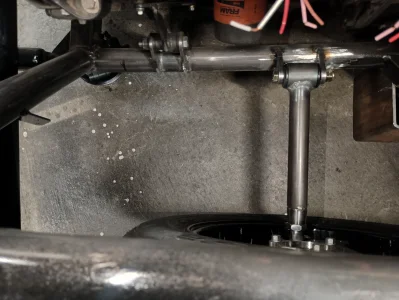

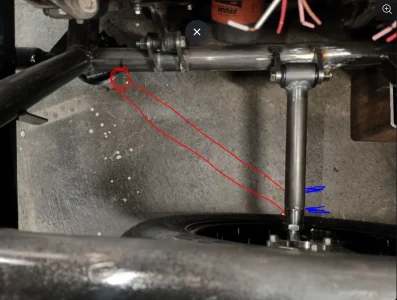

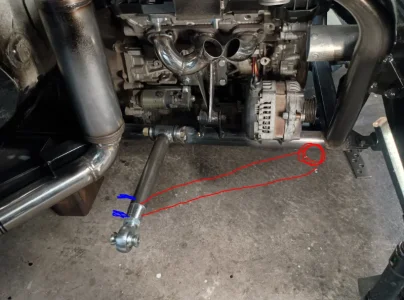

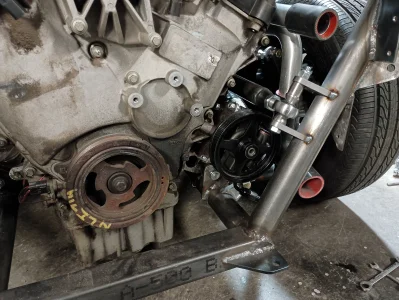

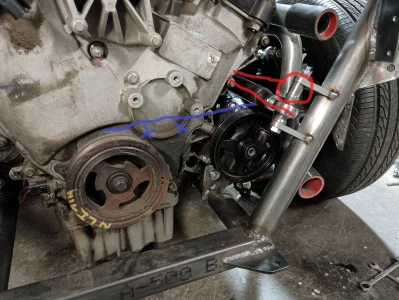

ok, so interestingly enough while fumbling pieces around i found out that if i run the uca from level up to 2 degrees (3/4") in the front i can gain 1.5 degrees in caster. kinda fun so i made a bushing in the front mount that i can adjust by makinng shims. i figure i will start with 0 degrees on the uca and about 8 degrees caster and see how it drives in about 4 years when its done. if i get some wild hair to fuck with it i can easliy add some control arm angle for some antidive. this is the red lines

the blue line is where the power steering belt is going and i have to sand down the stupid little perimeter lip. should be easy

the blue line is where the power steering belt is going and i have to sand down the stupid little perimeter lip. should be easy

Attachments

turbomonty

Well-known member

turbomonty

Well-known member

Similar threads

- Replies

- 34

- Views

- 772