DesertGoat

Well-known member

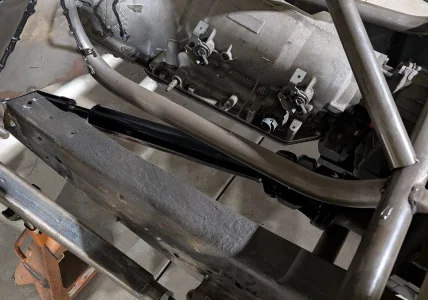

Making some progress on radiator mounting.

Gonna have the homie come weld these out for me next week once i'm done with the mockups & test fits. I gotta make sure I can still lift & wiggle the radiator out with these wings on it.

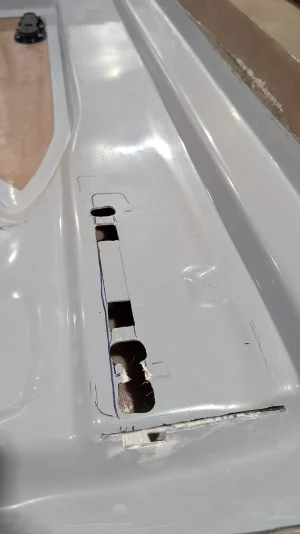

Also trying to get the hood mounted to double check clearances but that's requiring some fussiness, more on that later.

for this one, I just held it up there with a trick tab to show the idea, but I'm going to have to make my own steel tab that actually fits better than this

Gonna have the homie come weld these out for me next week once i'm done with the mockups & test fits. I gotta make sure I can still lift & wiggle the radiator out with these wings on it.

Also trying to get the hood mounted to double check clearances but that's requiring some fussiness, more on that later.

for this one, I just held it up there with a trick tab to show the idea, but I'm going to have to make my own steel tab that actually fits better than this