You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Local Legend Not much left Tacoma left... 4500 koh build

- Thread starter Hambone

- Start date

My dad came back for another few days and we got a lot done. He painted all the interior panels at home and fixed the fiberglass fenders.

We got everything mounted in the dash. The shifter mount done. The intake in. Figured out power steering hoses and got the resi and oil filter mounted. Shock resi mounts. Seat belt eyelets. Front sway bar done. Skid plates. And more I’m sure.

We got everything mounted in the dash. The shifter mount done. The intake in. Figured out power steering hoses and got the resi and oil filter mounted. Shock resi mounts. Seat belt eyelets. Front sway bar done. Skid plates. And more I’m sure.

Just a couple hours today. Neighbor kid has been coming over a lot and been a huge help. He’s getting better and I can turn him lose on easy projects so I can focus on other stuff. When you need 2 resivor mounts per shock it gets expensive to buy. So cut some on the cnc and had him bump break and shape them on some tubing to fit. Turned out good

We got the jack mount done. I welded some of the resi mounts. Got the shocks and all the coolers off and the last 3 skid plate tabs on (they went in the triangle corners of the subframe and got nuts welded in)

I’m making a strong push to get a lot of tabs and stuff done tomorrow and hopefully paint it this weekend. Next up is the carrier bearing mount, driveshaft loop tabs, and some more miscellaneous tabs then pull the motor and start pulling the axles.

We got the jack mount done. I welded some of the resi mounts. Got the shocks and all the coolers off and the last 3 skid plate tabs on (they went in the triangle corners of the subframe and got nuts welded in)

I’m making a strong push to get a lot of tabs and stuff done tomorrow and hopefully paint it this weekend. Next up is the carrier bearing mount, driveshaft loop tabs, and some more miscellaneous tabs then pull the motor and start pulling the axles.

badlinesgoodtimes

Administrator

- Joined

- Mar 30, 2022

- Messages

- 1,410

Thanks for the shoutout!

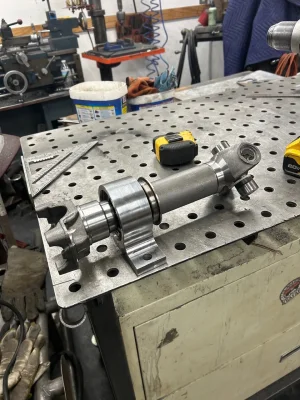

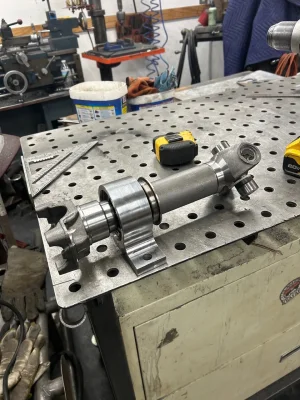

It seems like the small tabs and brackets never end. Screwed with the carrier bearing all day yesterday. Ended up having to make a front driveshaft and glad I did as clearance is tight but Everything fits. Mid shaft is less than a degree down and about a degree out to the side. And the actual front shaft is about 17 degrees down at full droop (20 degree max at the skip yoke) I did it out of 2x.120 but have some 2x.25 wall I’ll probably bore out and press on. Could videos on my Instagram showing how I did the carrier bearing.

Also got the driveshaft hoop tabs in, I’ll use an old limit strap. Added a brace to the winch tray as it had some flex. An antenna mount in the top wing thing.

Then today soent all day tearing everything apart while the wife sanded and scotch brighted the tubes. I got everything off the car and we got about 80-85% of the car sanded. I’ll finish sanding tomorrow and make a mock paint booth in the garage and start spraying the chassis.

Also got the driveshaft hoop tabs in, I’ll use an old limit strap. Added a brace to the winch tray as it had some flex. An antenna mount in the top wing thing.

Then today soent all day tearing everything apart while the wife sanded and scotch brighted the tubes. I got everything off the car and we got about 80-85% of the car sanded. I’ll finish sanding tomorrow and make a mock paint booth in the garage and start spraying the chassis.

What a mess. Painting was a ton of work and made a giant mess but the chassis and links are painted. Wife and I sanded the entire chassis then cleaned and tack clothed the entire thing.

Took about a day and half to prep and abour 4 hours to paint. There’s overspray everywhere despite making a paint booth with plastic. But it turned out good I think.

A few runs here and there and only found 2 small sections of tube I didn’t weld despite crawling all over the thing several times. I’ll clean them out and weld em up.

Just used the rustoleum gloss black in a gallon can. Thinned with acetone and added some hardener per some of the things I’ve seen online. Then sprayed through the cheap pink harbor freight gun. Sprayed no issue and laid flat. I’m happy.

Goal is to get the axles prepped tomorrow and then hopefully painted Monday. Then it’s time to start reassembling.

Took about a day and half to prep and abour 4 hours to paint. There’s overspray everywhere despite making a paint booth with plastic. But it turned out good I think.

A few runs here and there and only found 2 small sections of tube I didn’t weld despite crawling all over the thing several times. I’ll clean them out and weld em up.

Just used the rustoleum gloss black in a gallon can. Thinned with acetone and added some hardener per some of the things I’ve seen online. Then sprayed through the cheap pink harbor freight gun. Sprayed no issue and laid flat. I’m happy.

Goal is to get the axles prepped tomorrow and then hopefully painted Monday. Then it’s time to start reassembling.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

That is coming along great. Pro tip for next time, lay down the rolled butcher paper on the ground to keep the over-sprayed plastic from sticking to your shoes.

thanks I’ll try that next time. Had someone on Instagram say to wet the floor and tried that today and it worked decent tooThat is coming along great. Pro tip for next time, lay down the rolled butcher paper on the ground to keep the over-sprayed plastic from sticking to your shoes.

Got the rear housing brake calipers on and added fill/inspection holes on both housings. Then more sanding and cleaning and blasted everything with some paint. The garage will never be the same. Even with the paint booth attempt, overspray got on everything.

I have a few small parts to paint but I can finally start reassembling for the final time.

I have a few small parts to paint but I can finally start reassembling for the final time.

Finally some good progress. Panels going in. Trans is in but had to cut more of the passenger seat mount. It’ll get 3 interlocking tube disconnects and essentially the front middle seat mount will come out to get the trans and atlas in and out. With the torque converter in and flex plate on, they hit while lowering the trans in. I tested it with the torque converter but never the flex plate.

Pedals are bolted in. Radiator in. Oil filter. My mom painted the inside of the cab black for easy touch up and also got the skid plates painted.

Pedals are bolted in. Radiator in. Oil filter. My mom painted the inside of the cab black for easy touch up and also got the skid plates painted.

My dad and I got the Car about 75% plumbed. Still need to do brake lines and finish majority of the fuel lines. And I need two fittings to finish the oil cooler/filter lines. Feeling good about the progress.

My mom also painted the inside of the cab the same color as the chassis to make touch up easy. And got the skid plates painted.

My mom also painted the inside of the cab the same color as the chassis to make touch up easy. And got the skid plates painted.

Another easy win today. Garage Generator had an issue two days ago and was able to figure that out. So that was a relief as they aren’t cheap.

Got the axle shafts seal surfaces turned down and they fit in the third now. Went back and forth with a company as they were supposed to be stock spec shafts just chromoly, but they weren’t. So my off the shelf inner shaft housing now requires shafts to be modified on a lathe. I’ll end up ordering a set of shafts from Dutchman that I’ll run in the car and keep these modified ones for spares.

But got the passenger side assembled.

And a guy on Instagram, @Ultra4Jones was nice enough to send me 3 four piston wilwood calipers to use as spares. So if your on Instagram, give him a follow and buy some merch. He’s been a big help in answering questions reference the rules etc.

Got the axle shafts seal surfaces turned down and they fit in the third now. Went back and forth with a company as they were supposed to be stock spec shafts just chromoly, but they weren’t. So my off the shelf inner shaft housing now requires shafts to be modified on a lathe. I’ll end up ordering a set of shafts from Dutchman that I’ll run in the car and keep these modified ones for spares.

But got the passenger side assembled.

And a guy on Instagram, @Ultra4Jones was nice enough to send me 3 four piston wilwood calipers to use as spares. So if your on Instagram, give him a follow and buy some merch. He’s been a big help in answering questions reference the rules etc.

Front and rear axle are all together. Need to order some barbs to drill and tap the fill caps for breathers. I ordered a wfo skid for the front high pinion I’ll have to put on later. Put some foam tape on a few panels and got them installed. The tube connectors showed up to fix the seat so I’ll work on that tomorrow and get the fuel pumps mounted.

Finished fixing the passenger seat mount. Got the trans remote filter mount done and got the fuel cell plumbed minus the regulator mount and return. (Return is about half done). Also welded the one joint I found I missed and a capture nut I forgot to weld on the panhard. I painted the dash yesterday but it was still a little tacky so put it in the sun today to dry and tomorrow I’ll put everything in it and start figuring out wiring mounts etc.

Pretty happy with the lines on the fuel pumps. I bought the fuel filters super early on and bought -8 but later switched to -6 stuff so have a -8 100 and -8 10 micron aeromotive fuel filters for sale if anyone wants them. Brand new never used. Took them out of the boxes today for mockup.

I cut more resi mounts and used them to mount the fuel pumps and filters. Each one will have 2 hose clamps so they shouldn’t go anywhere.

Pretty happy with the lines on the fuel pumps. I bought the fuel filters super early on and bought -8 but later switched to -6 stuff so have a -8 100 and -8 10 micron aeromotive fuel filters for sale if anyone wants them. Brand new never used. Took them out of the boxes today for mockup.

I cut more resi mounts and used them to mount the fuel pumps and filters. Each one will have 2 hose clamps so they shouldn’t go anywhere.

Dash is pretty much assembled. I need to get some locking nuts for some of the stuff and loctite things but it’s all in. I’m putting this heat shield stuff on the back of panels that are around the engine. We will see if it does anything. Made the final panel for the middle between the seats out of some .040 aluminum and got the air filter mount done. The coupler by the dash will get a second clamp just for good measures. I’ll bead roll and paint it last as I think the battery switch and maybe the switch pros will end up there. And more fittings from fragola showed up to finish out the power steering and oil cooler.

My dad came down for another weekend and we got most the wiring knocked out. Wiring is my least favorite activity and I’m least knowledgeable about but we got most things done. Still have to do the fuel pumps and tail lights and finish looming but my wife helped loom the front today. Doesn’t look like much and still looks sloppy but with some zip ties and putting everything where it belongs, it’ll clean up. We have very minimal butt connectors and used deutsch connectors pretty much everywhere.

Time is slipping away and the list is still long but still plugging away.

Time is slipping away and the list is still long but still plugging away.

Similar threads

- Replies

- 10

- Views

- 262

- Replies

- 10

- Views

- 1K

- Replies

- 0

- Views

- 475