ADSRACINGSHOCKS

Active member

- Joined

- Jan 16, 2023

- Messages

- 79

NO OF COURSE NOT!

There are many opinions both good and bad revolving around leaf springs, the simplicity in design has many advantages for some, other scoff at the idea of them. Here are some realities to let you decide for your self if they are the best option.

- Cost There is no denying that leaf springs are more cost effective than a link style suspension, in some cases only slightly, custom springs for special applications can get very pricey but will nearly always beat out the cost of link type suspension.

- Simplicity Since the spring locates the axle and provides the load carrying there is no need for an addition spring system such as a coil-over, on our tow rigs we do add supplemental load support with air bags or overload springs generally not used in performance applications.

- Axle wrap One down side to relying on the spring to locate the axle and provide support, and being able to move is that, the pack is able to twist under throttle (axle wrap) this situation is not ideal but normally does not cause many issues, if axle wrap is too severe a torque arm can be added to eliminate this issue but it does add complexity to the system.

- Packaging As most vehicles come stock with leaf springs packaging is nearly seamless, whereas link suspension generally requires relocation of fuel tanks and crossmembers.

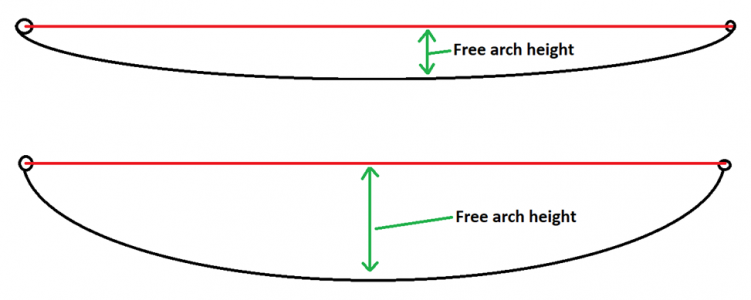

- Overall Travel With leaf springs we have a few limitations on available travel from any given pack, those factors are, free arch of the spring and shackle orientation/length. In the diagram below you can see the spring with the larger free arch as more travel potential, this spring will also increase its length more as it compresses which changes wheelbase more throughout the cycle.

- This added length will also require a longer shackle to allow uninhibited travel. Think about a Deaver F67 on a Tacoma they run 11-13” shackle length, Where a stock style Tacoma may have a 3-5”

- Your short free arch spring will generally be found as a spring over axle configuration, and high free arch as a spring under axle configuration.

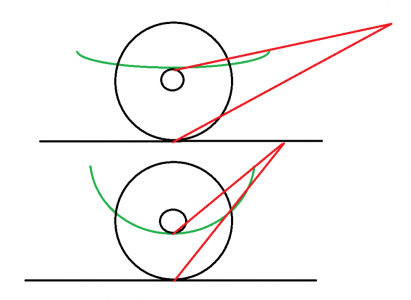

- Anti-squat is also effected by which type of spring configuration is used, spring over axle will generally has less anti squat than a spring under, due to the moment arm geometry changing between the two. This factor all depends on how much power you are providing to the moment arm. See diagram below.

- (These examples are extreme to easily display the differences)

- Shackle type, there are 2 common types of shackles being used today. Tension and compression style. See diagram.

- You can use either type on both spring types, but packaging will change for each. There are tricks to gain additional droop from a tension style shackle, personally I am not a fan of them as it is “dead” travel with no spring rate pushing out, you are solely relying on gravity to pull the axle out, not thing wrong with it but it does not stay active in deep whoops, which is why they need very little rebound control on droop. A compression style shackle will stay under spring force just until to reaches its free arch, which may be less overall wheel travel but has spring force through its full cycle aiding in traction.

- Which is best for your application? That will be up to the vehicle and effort your willing to put into the combo, most bolt on kits are pretty close to ideal for the platform. Staying spring over normally means no fabrication or welding but to get more free arch you may gain ride height so keep that in mind, bolt in shock options are available for these “extended travel” springs. Going spring under will normally unlock more up travel as well as droop, but will require some fab work in the form of spring perches and shock mounts, normally when doing spring under your going to a bed cage and a 16” or 18” shock obviously of the ADS 5 tube flavor