BlazeOrange3

Active member

- Joined

- May 3, 2023

- Messages

- 31

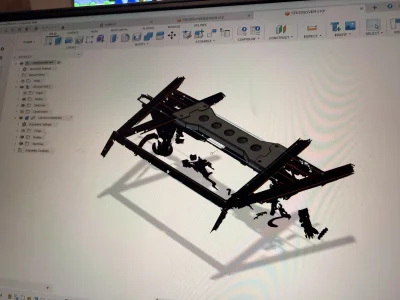

Chopped off the LCA shock mounts and reset the suspension at new full compression on passenger side. With a bit of playing with the arrangement im sitting around 16.5” of clean travel, aproximafley 50-50 down/up travel. Previously around 12” of travel, so the result should be a massive improvement.

Now working on boxed shock mounts via cardboard aided design and replicating on drivers side. Then placing steering box in the chassis for the swing steer after I get an older model that has 1/2” bolts, instead of the 14mm version I currently have.

Now working on boxed shock mounts via cardboard aided design and replicating on drivers side. Then placing steering box in the chassis for the swing steer after I get an older model that has 1/2” bolts, instead of the 14mm version I currently have.