Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 976

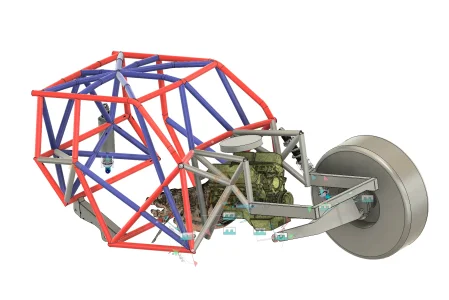

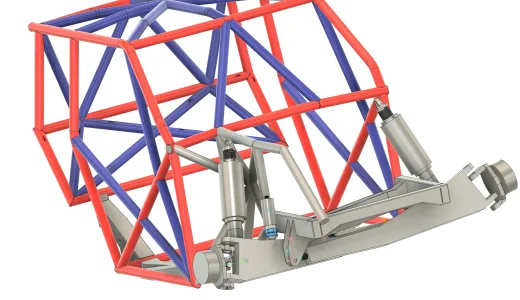

Awesome work!! The time put into all the mechanism design and constraints in Fusion is impressive.I have respect for the guys who spend weeks doing steering geometry by hand, with a million holes and suspension cycles later.

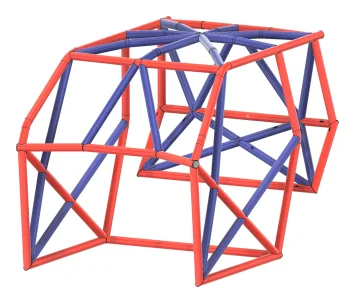

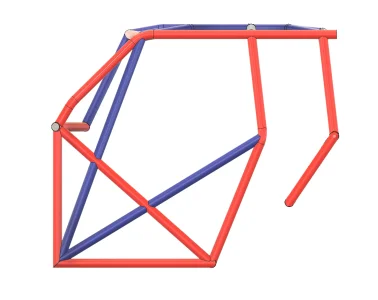

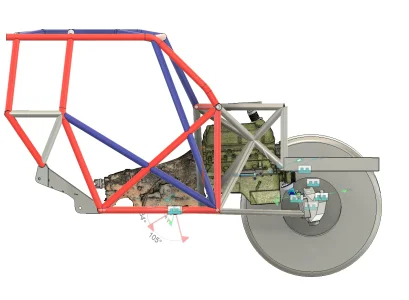

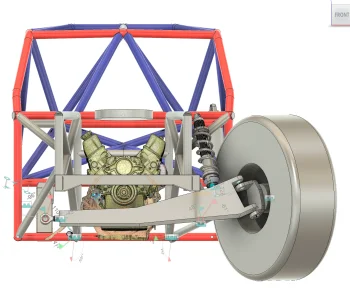

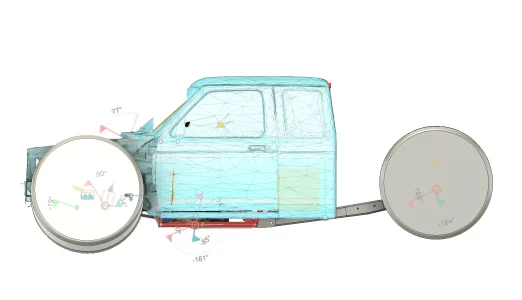

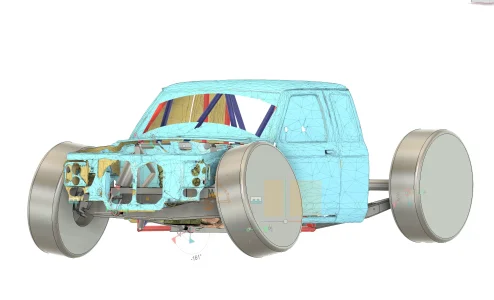

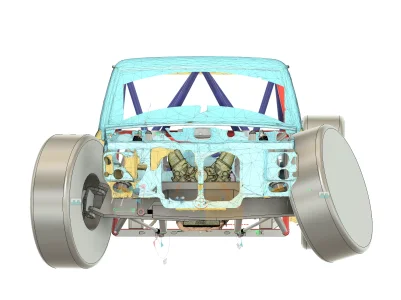

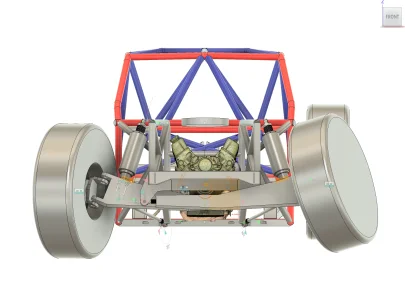

Spent the day chasing issues but finally at a point where I am content to move along and make the small changes when its getting assembled. With a 14" Coilover in the front, the truck is hitting 30" metal to metal. I don't even think that's possible but regardless its getting strapped well short at around 23-24"

Was able to "eliminate" bumpsteer through ride height and full bump, have about 1" of toe in at full droop but should be negligible where I end up strapping it at. Deciding on using 2x4x.188 rails from the firewall forward to mount everything. I tossed around the idea of having all the suspension/steering tie into tubing and sheet metal work, but with my luck I'll need to adjust mounts afterward and would rather have the ease of a square frame to do it on.

Definitely a lot of time on the computer, but I am appreciative of being able to reverse a timeline rather than cut half my truck apart on a mistake I made (ask me how I know)

The 30” travel number doesn’t sound too far off… the old Herbst chevy beamed prerunners had like 28” of front travel.

Without a bypass, my Ranger cycles 25” travel on a 14” coilover, and it’s only like 80” wide—so your numbers seem legit