First the truck started off as a completely stock SLE that I bought brand new in 2015 with no plans of getting into this hobby as I was much too focused on dirt bike riding

In 2017 I then broke my spine in a dirt bike crash leaving me in rods and screws in my back, so in an effort to go towards something safer I started to look at building a truck.

Going through many different brand options and to be completely transparent I hardly knew what I was looking at I bought a

CWF bolt on long travel kit.

2.5x8 inch king c/o

Fiberwerx 6” CF fenders front and rear

Method mr106 wheels and toyo R/t 37/13.50 tires

I was super thrilled with this stage of the truck but through conversations and learning I found that I was left just wanting more and I was stuck cleaning up the mistakes I made through uninformed purchases.

First of my issues is the offset on the wheels was a -44 which adds a lot more stress on the stock hubs, and also seeing multiple shock buckets get torn off I really wanted to upgrade to a proper “race kit” (depending on the brands marketing) or true long travel kit with fabricated shock towers.

When I was shopping for kits mz was not making them and I had the options of LSK or Dirt King left.

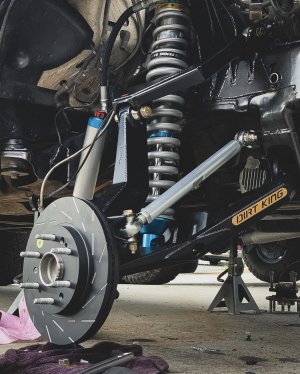

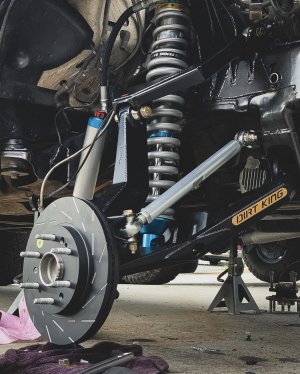

I landed on the Dirt King race kit and 2.5x10 IBP coilovers that I installed in a driveway with the help of a few buddies.

I chose dirt king due to the upper arms mounting over the frame rails allowing for (in my opinion) a slightly better geometry. And with the taller upright it has a lower scrub radius. It also included billet tie rods and FK heims standard while the other kit had to be upgraded to those.

This was a much more involved process than I had anticipated going in but the kit went together great and the proper kit was noticed as soon as I drove it. The steering immediately felt much lighter due to the scrub and the control of the wheel over bumps was effortless while the prior kit had almost been scary to drive with.

Shortly later I then bought a new set of beadlocks with a -12 offset in order to take the stress of the hubs even more and bring in the scrub to what the kit was designed for.

I went with MR103 methods due to them being one of the strongest load ratings of the beadlocks on the market and I really wanted to try the polished wheel look.

Here’s where the road started to get bumpy…

I started the process of moving to the rear suspension with the plan on using some 2.5x18 pr coilovers… and some simple tubes to the rear end using the GFW link mounts.

Well… through the obsession of geometry and not wanting to buy parts twice this has snowballed.

What was 2.5 coilovers is now 3.0 IBP coilovers for the rear

What was supposed to be GFW link mounts is now tig welded izzyfab link mounts

What was tubes has now turned into izzyfab tig welded lower links and billet upper links

What was supposed to be a trussed 12b is now a FF camburg rear end

And what was supposed to be a c notch is now Izzy fab frame kicks

And what was supposed to be a bedcage is now an izzyfab trunk and insert.

And what was supposed to be fresh 37s is now 40” KR3s

This has all been collected slowly but surely, hunting race dezert daily, selloffroad on IG and just word of mouth.

3.0x18 RS coilovers with XL race finned resis and comp adj

GMT 900 Izzy fab frame kicks and link mounts

4130 TIG

Picked up a Camburg 76” WMS 3.50 rear end

2.50 hubs

Camburg 2.0 GM front hubs

Yukon third with 4.88 gears

6 piston wilwoods 12” rotors

Opted for a PCI intercom and Kenwood radio system

2.5x4 bolt on style bumps for the rear

Got these 55” tig 4130 lower links and billet uppers from Izzyfab

Got these PRP custom alphas for the seats

This is the izzyfab tig welded trunk set up and ready to go.

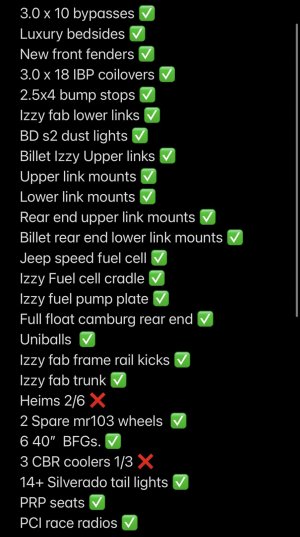

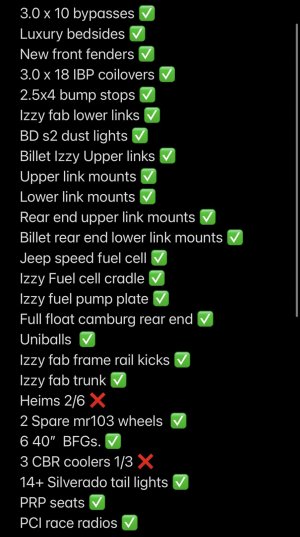

here’s the list of parts collected so far, there’s im sure a few smaller things I didn’t post but if this raises any questions I’m happy to answer the why this vs that etc. and I’ll post more on here after she goes under the knife in a couple months here!

Thanks for checking it out